Motor Electronics

How has the development of power electronics influenced the design of modern drive motors ?

The advancement of power electronics has significantly influenced the design and performance of contemporary drive motors. This technological progress has led to more efficient, reliable, and sophisticated motor control systems, offering a wide array of benefits across various sectors. Here are some key points: - **Enhanced Efficiency and Performance**: Power electronics have enabled advanced control techniques like FOC and DTC, optimizing motor operation for better dynamic response and efficiency. The introduction of VFDs allows motors to operate at varying speeds without mechanical gearboxes or belt drives, enhancing energy efficiency and reducing mechanical wear. - **Improved Reliability and Durability**: Integrated power electronics can monitor motor conditions in real-time, enabling predictive maintenance that reduces downtime and repair costs. Modern drive motors often include protection features like overcurrent, overvoltage, and temperature monitoring, thanks to the integration of power electronics. These safeguards extend the motor's lifespan and ensure stable operation. - **Customizable and Smarter Motors**: Power electronics enable motors with programmable settings that can be tailored to specific applications, improving performance and adaptability. The inclusion of power electronics paves the way for IoT integration, where motors can communicate with other devices, enabling smart grid functionalities and remote diagnostics. - **Environmental Benefits**: By allowing motors to operate at optimal speeds and loads, power electronics contribute to significant energy savings, aligning with global efforts to reduce energy consumption and greenhouse gas emissions. Modern drive motors utilizing power electronics often operate more smoothly, resulting in reduced noise pollution compared to traditional motor designs. - **Scalability and Cost-Effectiveness**: Power electronic components can be designed modularly, making it easier to scale motor designs up or down to meet specific power requirements without starting from scratch. As power electronic components become more standardized and mass-produced, their cost decreases, making advanced motor designs more accessible to a broader range of industries and applications.

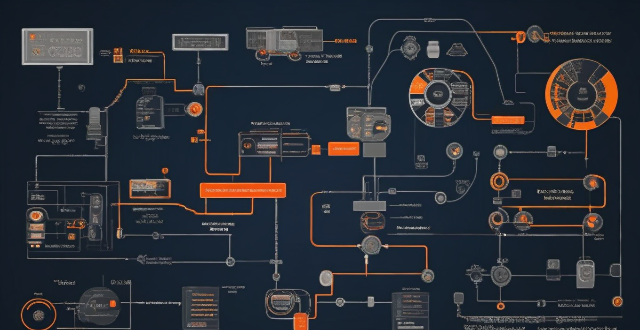

How does a multi-motor drive system work ?

The text explains how a multi-motor drive system works, its components, and benefits. It describes the process of power conversion, control signals, motor operation, mechanical transmission, and feedback adjustment in such systems. The advantages include improved efficiency, increased redundancy, and enhanced control.

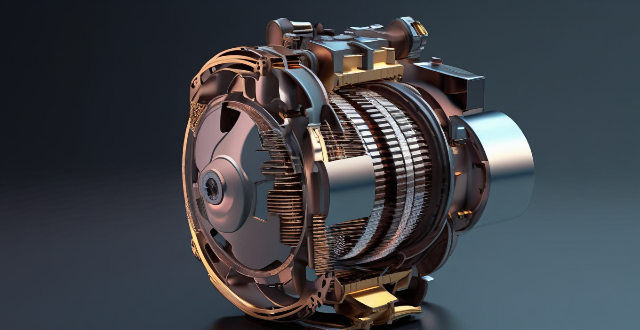

What is an internal rotor motor ?

The text discusses the design, advantages, disadvantages, and applications of internal rotor motors. Internal rotor motors are a type of electric motor where the moving part (rotor) is inside the stationary part (stator). They offer benefits such as high efficiency, good heat dissipation, simplicity in construction, and low inertia. However, they also have limitations like limited torque density, difficulty in cooling, and potential for magnetic saturation. These motors are commonly used in automotive, aerospace, industrial equipment, and consumer electronics applications.

Which is the best online shopping site for electronics ?

When it comes to buying electronics online, there are several factors that you need to consider before making a decision. These factors include price, selection, customer service, and shipping options. In this article, we will explore some of the best online shopping sites for electronics and help you make an informed decision. Amazon is one of the most popular online shopping sites for electronics. It offers a wide range of products at competitive prices, with fast and reliable shipping options. Best Buy is another great option for buying electronics online. It offers a wide range of products, including TVs, audio systems, cameras, and home appliances. Newegg is a popular online shopping site for computer hardware and accessories. It offers a wide range of products, including CPUs, GPUs, motherboards, and RAM. B&H Photo Video is a popular online shopping site for photography and video equipment. It offers a wide range of products, including cameras, lenses, tripods, and lighting equipment.

Is it safe to donate used electronics for recycling purposes ?

Is it Safe to Donate Used Electronics for Recycling Purposes? Introduction: Donating used electronics for recycling purposes is a common practice that has both environmental and social benefits. However, many people are concerned about the safety of donating their old electronic devices. In this article, we will explore whether it is safe to donate used electronics for recycling purposes. Safety Concerns: When donating used electronics, there are several safety concerns that need to be addressed: 1. Data Security: Old electronic devices may contain sensitive personal information, such as photos, documents, and login credentials. Donating these devices without properly erasing the data can lead to identity theft and other security breaches. 2. Environmental Impact: Improper disposal of electronic waste can harm the environment. Toxic chemicals in electronic devices can contaminate soil and water sources if not disposed of correctly. 3. Physical Safety: Some electronic devices may contain hazardous materials, such as batteries or capacitors, that can cause injury if not handled properly. Benefits of Donating Used Electronics: Despite these concerns, there are several benefits to donating used electronics for recycling purposes: 1. Reduced Landfill Waste: By donating used electronics for recycling, you reduce the amount of waste that ends up in landfills. This helps conserve natural resources and protect the environment. 2. Resource Conservation: Recycling electronic devices conserves valuable resources, such as metals and plastics, that can be reused in new products. 3. Support for Charitable Causes: Many organizations accept donated electronics to support charitable causes, such as providing technology access to underprivileged communities or funding research initiatives. Best Practices for Safe Donation: To ensure the safety of donating used electronics for recycling purposes, follow these best practices: 1. Wipe Your Data: Before donating your device, make sure to wipe all personal data from it. Use a data erasure software or perform a factory reset on the device. 2. Choose a Trusted Recycler: Research recycling centers or organizations before donating your device. Look for reputable organizations that have experience in handling electronic waste safely. 3. Properly Pack and Ship Your Device: If you are shipping your device, make sure to pack it securely to prevent damage during transit. Use bubble wrap or packing peanuts to cushion the device and place it in a sturdy box. 4. Label Your Device: Clearly label your device with any relevant information, such as its condition or any known issues. This helps the recycler assess the device accurately and determine the appropriate recycling method. Conclusion: In conclusion, donating used electronics for recycling purposes can be safe when done correctly. By following best practices for data security, environmental impact, and physical safety, you can contribute to reducing electronic waste while supporting charitable causes. Always choose a trusted recycler and take necessary precautions when preparing your device for donation.

Can you explain the concept of vector control in multi-motor drives ?

Vector control is a method for controlling the speed and torque of electric motors, especially AC motors, in multi-motor drives. It works by decoupling the flux-producing and torque-producing components of the stator current, allowing for independent control of both. This results in improved dynamic response, precise speed regulation, energy efficiency, reduced mechanical stress, and adaptability to different motor types.

How does a single motor drive work ?

The motor drive converts incoming AC power to DC, controls the motor's speed via PWM, regulates its torque by monitoring current and adjusting voltage, and ensures proper operation through feedback control.

What is the difference between single motor and multi-motor drives ?

Single motor drives control only one motor and are simple, cost-effective, and easy to maintain. Multi-motor drives control multiple motors simultaneously and offer increased flexibility, improved performance, and enhanced functionality but are more complex and expensive. The choice between these two types of drives depends on the specific requirements of the application.

What is a hub motor ?

A hub motor is an electric motor integrated into a vehicle's wheel hub, offering direct drive, simplified design, quiet operation, and space efficiency. However, it has limitations such as limited power output, overheating concerns, and cost considerations. Hub motors are commonly used in electric vehicles like bicycles, scooters, motorcycles, and cars.

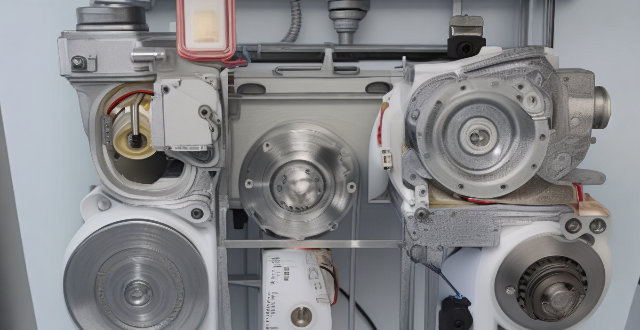

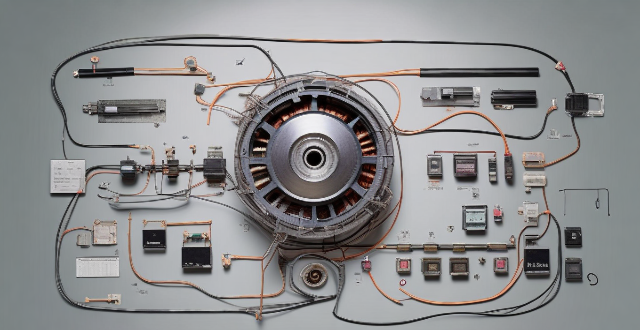

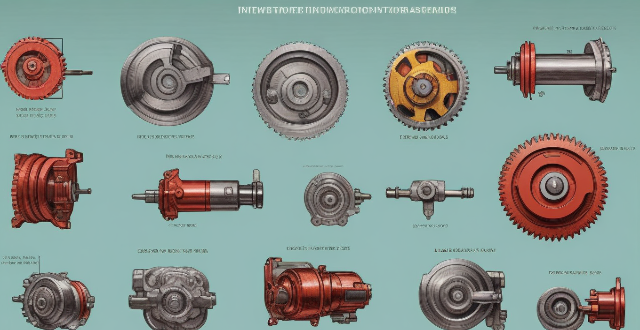

How is an electromagnetic motor designed and constructed ?

Design and construction of an electromagnetic motor involves selecting appropriate components, determining specifications, choosing the type of motor, designing the stator and rotor, calculating winding patterns, assembling the motor, installing a commutator if applicable, connecting wiring and control electronics, testing and troubleshooting, and finalizing and optimizing the design. The key components include the stator, rotor, bearings, commutator, and armature. The steps ensure that the motor meets the required specifications and operates efficiently for its intended use.

How do you choose the right AC stepping motor for your project ?

Choosing the right AC stepping motor requires understanding project needs, selecting the appropriate motor type, ensuring compatibility with control systems, considering physical constraints, evaluating performance characteristics, accounting for environmental factors, managing budgetary considerations, relying on supplier support and reputation, and conducting thorough testing.

Can you provide some examples of applications where multi-motor drives are used ?

Multi-motor drives are used in various applications where multiple motors need to be controlled simultaneously, including industrial automation, CNC machines, electric vehicles, wind turbines, robotics, and aerospace.

Can a combination motor drive improve energy efficiency in my facility ?

Combination motor drives can improve energy efficiency in facilities by optimizing electric motor performance, reducing energy consumption, and extending equipment lifespan. They offer variable speed control, soft start/stop capabilities, and reactive power compensation features that contribute to lower energy bills, reduced maintenance costs, and environmental benefits like reduced greenhouse gas emissions.

How does a single motor drive compare to a dual motor drive ?

This article compares single motor drives and dual motor drives based on their performance, efficiency, cost, and applications. Single motor drives can only control one motor at a time, while dual motor drives can control two motors simultaneously. Dual motor drives offer higher overall torque and better synchronization between multiple motors, but they also consume more power and require more maintenance. Single motor drives are typically less expensive and well-suited for low power applications with simple movement profiles, while dual motor drives are appropriate for high power applications with complex movement profiles requiring precise synchronization. The choice between a single motor drive and a dual motor drive depends on the specific requirements of the application.

What are the advantages of using an electromagnetic motor ?

The text is a summary of the advantages of using an electromagnetic motor, which include high efficiency, long lifespan, low noise levels, precise control, and environmental friendliness. These benefits make electromagnetic motors a preferred choice for various applications, from industrial machinery to consumer electronics.

What are the advantages and disadvantages of using a combination motor drive compared to a single motor drive ?

The combination motor drive has several advantages over a single motor drive, including improved performance, enhanced reliability, flexibility in design, energy efficiency, and modularity and scalability. However, it also has disadvantages such as complexity, cost, space requirements, synchronization issues, and integration challenges.

How does the design of a permanent magnet motor differ from an induction motor ?

The article discusses the differences between permanent magnet motor and induction motor design, focusing on three main aspects: rotor design, stator winding design, and cooling system. The rotor of a permanent magnet motor contains high-energy rare-earth magnets that interact with the stator windings to produce torque, while the rotor of an induction motor has aluminum or copper bars that induce currents when exposed to a rotating magnetic field produced by the stator windings. The stator winding design also varies between the two types of motors, with permanent magnet motors typically having a three-phase distributed winding and induction motors having either a distributed or concentrated winding. Finally, the cooling system design differs as well, with permanent magnet motors often relying on natural convection or forced air cooling, while induction motors may use external fans or blowers for more effective heat removal. Understanding these differences is crucial for engineers to choose the appropriate motor type for their needs and optimize its performance accordingly.

How do you maintain and troubleshoot a DC brushed motor ?

Maintaining and Troubleshooting a DC Brushed Motor involves regular cleaning, lubrication, brush replacement, heat management, and monitoring voltage and current. Troubleshooting steps include checking for no power, reduced performance, excessive heat, vibration or noise, sparking, intermittent operation, and smoke or burning smell. Proper maintenance and troubleshooting can prolong the lifespan and ensure reliable operation of the motor.

How does a multi-motor drive system contribute to energy savings in industrial processes ?

A multi-motor drive system contributes to energy savings in industrial processes by optimizing the operation of multiple motors. It balances loads, controls speed optimally, provides reactive power compensation, enables regenerative braking, and reduces maintenance costs. This technology helps businesses improve their bottom line while reducing their environmental footprint.

What is a drive motor and how does it work ?

A drive motor, also known as a motor or electric motor, is a device that converts electrical energy into mechanical energy. It operates on the principle of electromagnetism, using magnetic fields to produce motion. Drive motors are used in various applications such as transportation, industrial machinery, and consumer electronics. The working principle of a drive motor is based on **electromagnetic induction**, which refers to the process of generating an electric current within a conductor when it is exposed to a changing magnetic field. In a typical AC (Alternating Current) motor, a rotating magnetic field is created inside the motor using multiple coils of wire connected to an alternating current source. The alternating current causes the direction of the magnetic field produced by each coil to change continuously. As these fields change, they create a rotational force called **torque**, which turns the motor shaft. The interaction between the rotating magnetic field and the stationary part of the motor generates motion. This movement can be harnessed to perform work, such as driving a fan blade or lifting weights. The components of a drive motor include the stator, rotor, bearings, windings, commutator (in DC motors), and shaft. There are several types of drive motors, including DC Motors, AC Motors, Stepper Motors, and Servo Motors. Each type has its advantages and disadvantages, making it suitable for specific applications based on factors like efficiency, size, cost, and control complexity.

What are the benefits of using a combination motor drive system ?

Combination motor drive systems offer benefits such as improved efficiency, increased reliability, flexibility, and enhanced control. These systems combine the advantages of different types of motors to create a more efficient and reliable drive system. They are ideal for a wide range of applications and can help businesses save money on energy costs while reducing downtime and maintenance requirements.

How do I choose the right drive motor for my application ?

When selecting a drive motor for your application, considerWhen selecting a drive motor for your application, considerrque and speed, power duty cycle, cost, size, control compatibility, safety compliance, maintenance, and manufacturer reputation. This comprehensive guide helps ensure you choose a motor that meets your needs effectively and efficiently.

What are the advantages of using a brushless motor ?

Brushless motors offer several advantages over traditional brushed motors, including higher efficiency, longer lifespan, improved performance, quieter operation, enhanced reliability, and environmental benefits. These benefits make them an attractive choice for a wide range of applications.

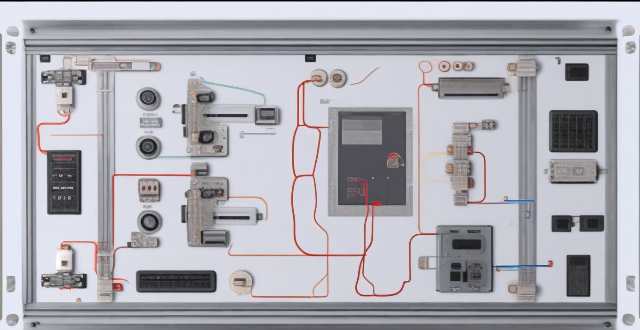

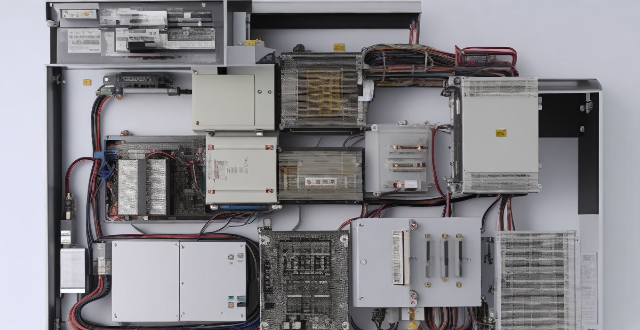

How does a combination motor drive work ?

Combination motor drives integrate VFD and servo controller functionalities to achieve precise speed and torque control for AC induction and permanent magnet synchronous motors. They enhance performance, reduce energy consumption, and extend motor lifespan by offering smooth speed control and reducing wear and tear. Key components include a VFD, servo controller, electric motor, encoder, and user interface. The system uses feedback from an encoder to adjust the motor's input signals, ensuring accurate motion profiles.

How does a brushless motor work ?

Brushless motors, also known as BLDC motors, are electric motors that use an electronic controller to switch the current in their stator windings. They consist of three main components: the rotor, stator, and electronic controller. The working principle of a brushless motor involves initial rotation, commutation, and maintaining rotation. Brushless motors offer several advantages over traditional brushed motors, including higher efficiency, longer lifespan, better performance, and lower maintenance.

Is it possible to convert an internal rotor motor into an external rotor one, and vice versa ?

Converting an internal rotor motor into an external rotor one and vice versa is possible but not straightforward. It requires significant modifications to the motor's design and components, which can be costly and time-consuming. Moreover, the performance of the converted motor may not meet the original specifications or expectations. Therefore, it is essential to carefully evaluate the benefits and drawbacks of such a conversion before proceeding.

How does a DC brushed motor compare to a DC brushless motor in terms of efficiency and performance ?

The text provides a comparison between DC Brushed Motor and DC Brushless Motor in terms of efficiency, performance, and lifespan. DC brushed motors have lower efficiency due to energy loss caused by friction between the brushes and the commutator, while DC brushless motors are more efficient as there are no brushes to cause friction. In terms of performance, DC brushed motors are limited due to physical limitations of the brushes and commutator, while DC brushless motors offer improved performance with higher RPM and power output. Overall, a DC brushless motor is generally superior to a DC brushed motor in terms of efficiency, performance, and lifespan.

What are the advantages of using a single motor drive system ?

A single motor drive system is a type of electric motor control system that uses only one motor to power a machine or equipment. This system has several advantages over other types of drive systems, including simplified design and maintenance, improved efficiency and performance, increased reliability and longevity, and greater flexibility and versatility. These benefits make it an attractive option for many industrial applications where precise control and efficient operation are essential.

What are the different types of combination motor drives available in the market ?

The article discusses different types of combination motor drives, including AC, DC, servo, and stepper motor drives. It highlights their unique features such as precise speed control, high torque output, regenerative braking, position control, feedback systems, and microstepping capabilities. The article emphasizes the importance of selecting the appropriate type of motor drive based on the specific needs and requirements of the application.

Are there any safety concerns associated with using a combination motor drive ?

The text discusses the safety concerns associated with using combination motor drives, which combine the functions of an electric motor and a gearbox. Safety issues include electrical hazards such as overheating and electrical shock, mechanical hazards like gearbox failure and injuries from rotating parts, and chemical hazards from lubricants and fluids. To ensure safe operation, it is important to follow proper safety procedures, regularly maintain the equipment, and use appropriate personal protective equipment.