Design and construction of an electromagnetic motor involves selecting appropriate components, determining specifications, choosing the type of motor, designing the stator and rotor, calculating winding patterns, assembling the motor, installing a commutator if applicable, connecting wiring and control electronics, testing and troubleshooting, and finalizing and optimizing the design. The key components include the stator, rotor, bearings, commutator, and armature. The steps ensure that the motor meets the required specifications and operates efficiently for its intended use.

Design and Construction of an Electromagnetic Motor

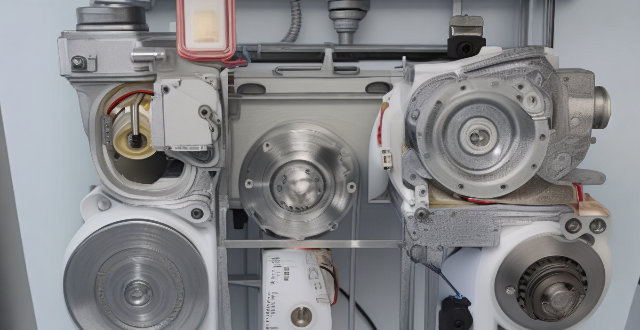

An electromagnetic motor is a device that converts electrical energy into mechanical energy. It operates on the principle of electromagnetism, which states that when an electric current flows through a conductor, it creates a magnetic field around it. This magnetic field can be used to produce motion in a motor. The design and construction of an electromagnetic motor involve several key components and steps.

Key Components of an Electromagnetic Motor

1. Stator: The stator is the stationary part of the motor, usually made up of a series of coils or magnets.

2. Rotor: The rotor is the moving part of the motor, typically consisting of a shaft with attached wire windings or permanent magnets.

3. Bearings: Bearings support the rotor and allow it to rotate smoothly within the stator.

4. Commutator: In some types of electromagnetic motors, such as DC motors, a commutator is used to reverse the current flow in the rotor windings at the appropriate time.

5. Armorature: The armature is the rotating part of the motor where the current flows and generates the magnetic field.

Steps in Designing and Constructing an Electromagnetic Motor

1. Determine the Purpose and Specifications: Before designing an electromagnetic motor, you need to determine its intended use and required specifications, such as power output, speed, torque, and efficiency.

2. Choose the Type of Motor: There are various types of electromagnetic motors, including DC motors, AC motors, stepper motors, and servo motors. Each type has its advantages and disadvantages depending on the application. Choose the appropriate type based on your requirements.

3. Design the Stator and Rotor: Once you have chosen the type of motor, design the stator and rotor according to your specifications. This involves selecting the appropriate materials for the core (usually iron or steel) and determining the number of turns in each coil or magnet size.

4. Calculate Winding Patterns: For motors with coils, calculate the winding patterns for both the stator and rotor. This involves determining the number of turns per coil, the wire gauge, and the arrangement of the coils.

5. Assemble the Motor: After designing and calculating all necessary components, assemble the motor by attaching the stator and rotor to their respective housings or frames. Install bearings to support the rotor and ensure smooth rotation.

6. Install the Commutator (if applicable): If you are building a DC motor, install the commutator to reverse the current flow in the rotor windings at the appropriate time.

7. Connect Wiring and Control Electronics: Connect wiring to the stator and rotor windings, and install any control electronics needed to regulate voltage and current supply to the motor.

8. Test and Troubleshoot: Test the motor under various load conditions to ensure it meets your specifications. Troubleshoot any issues that may arise during testing and make adjustments as necessary.

9. Finalize and Optimize: Once the motor is functioning correctly, finalize the design by adding any necessary mounting hardware or protective coverings. Optimize performance by fine-tuning parameters such as voltage levels or winding configurations.

In conclusion, designing and constructing an electromagnetic motor requires careful consideration of various factors such as purpose, specifications, type of motor, winding patterns, assembly techniques, and control electronics. By following these steps and using appropriate materials and components, you can create a functional and efficient electromagnetic motor for your desired application.