Single motor drives control only one motor and are simple, cost-effective, and easy to maintain. Multi-motor drives control multiple motors simultaneously and offer increased flexibility, improved performance, and enhanced functionality but are more complex and expensive. The choice between these two types of drives depends on the specific requirements of the application.

Single Motor Drive vs. Multi-Motor Drive

Introduction

In the realm of mechatronics and robotics, motor drives are crucial components that control the operation of motors. There are two main types of motor drives: single motor drive and multi-motor drive. This article will delve into the differences between these two types of drives.

Single Motor Drive

A single motor drive is a system that controls only one motor. It is typically used in applications where only one motor is needed to perform a task. The advantages of using a single motor drive include simplicity, cost-effectiveness, and ease of maintenance. However, it may not be suitable for applications that require multiple motors to work together or have different speeds and torque requirements.

Key Points:

- Controls only one motor

- Simple and cost-effective

- Ease of maintenance

- Limited to applications with a single motor requirement

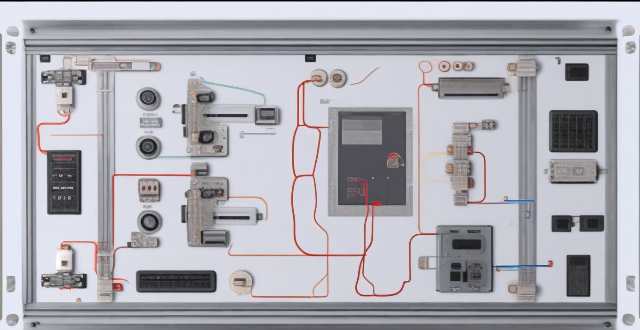

Multi-Motor Drive

On the other hand, a multi-motor drive is a system that can control multiple motors simultaneously. It is commonly used in applications where multiple motors need to work together or have different speeds and torque requirements. The advantages of using a multi-motor drive include increased flexibility, improved performance, and enhanced functionality. However, it may be more complex and expensive than a single motor drive.

Key Points:

- Controls multiple motors simultaneously

- Increased flexibility and improved performance

- Enhanced functionality

- More complex and expensive than a single motor drive

Differences Between Single Motor Drive and Multi-Motor Drive

Simplicity

Single motor drives are simpler than multi-motor drives because they only control one motor. This makes them easier to understand, install, and maintain. In contrast, multi-motor drives are more complex due to the additional components required to control multiple motors simultaneously.

Cost

Single motor drives are generally less expensive than multi-motor drives because they require fewer components and less wiring. Multi-motor drives, on the other hand, may require additional hardware and software, which can increase their overall cost.

Performance

Multi-motor drives offer better performance than single motor drives because they can control multiple motors simultaneously, allowing for greater flexibility and improved functionality. For example, in an industrial automation application, a multi-motor drive could be used to coordinate the movement of several robotic arms at once.

Maintenance

Single motor drives are generally easier to maintain than multi-motor drives because they have fewer components that can fail or require replacement. In contrast, multi-motor drives may require more frequent maintenance due to the additional components and complexity of the system.

Applications

Single motor drives are typically used in applications where only one motor is needed to perform a task, such as conveyor belts or simple machine tools. Multi-motor drives are commonly used in applications where multiple motors need to work together or have different speeds and torque requirements, such as industrial automation or robotics.

Conclusion

In conclusion, there are several differences between single motor drives and multi-motor drives. Single motor drives are simpler, less expensive, and easier to maintain than multi-motor drives. However, multi-motor drives offer better performance and greater flexibility than single motor drives. The choice between these two types of drives depends on the specific requirements of the application.