Converting an internal rotor motor into an external rotor one and vice versa is possible but not straightforward. It requires significant modifications to the motor's design and components, which can be costly and time-consuming. Moreover, the performance of the converted motor may not meet the original specifications or expectations. Therefore, it is essential to carefully evaluate the benefits and drawbacks of such a conversion before proceeding.

Is it Possible to Convert an Internal Rotor Motor into an External Rotor One, and Vice Versa?

Introduction

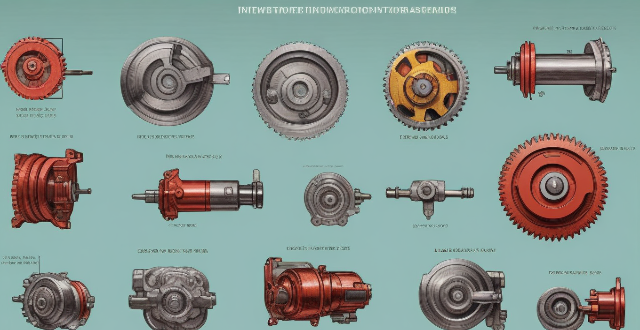

Motors are essential components in many applications, from electric vehicles to industrial machinery. They come in various types, including internal rotor motors and external rotor motors. The main difference between these two types of motors is the location of the rotor. In an internal rotor motor, the rotor is inside the stator, while in an external rotor motor, the rotor surrounds the stator. This article discusses whether it is possible to convert an internal rotor motor into an external rotor one and vice versa.

Main Body

Internal Rotor Motors

An internal rotor motor consists of a rotor that is located inside the stator. The stator is made up of windings that create a magnetic field when an electrical current flows through them. The rotor contains permanent magnets or electromagnets that interact with the magnetic field produced by the stator. This interaction causes the rotor to rotate, producing mechanical energy.

External Rotor Motors

An external rotor motor, on the other hand, has a rotor that surrounds the stator. The stator is typically fixed, while the rotor rotates around it. The rotor also contains permanent magnets or electromagnets that interact with the magnetic field produced by the stator. This interaction causes the rotor to rotate, producing mechanical energy.

Conversion Possibilities

Converting an internal rotor motor into an external rotor one and vice versa is not a straightforward process. It requires significant modifications to the motor's design and components. Here are some factors to consider:

1. Magnetic Field: The magnetic field generated by the stator and rotor must be compatible for both types of motors. If not, additional components may be needed to modify the magnetic field.

2. Mechanical Structure: The mechanical structure of the motor must be altered to accommodate the new configuration. This may involve changing the size and shape of the rotor and stator, as well as their mounting points.

3. Electrical Connections: The electrical connections must be modified to match the new configuration. This may involve rewiring the motor or replacing its controller.

4. Performance: The performance of the motor may be affected by the conversion. For example, an external rotor motor may have lower efficiency than an internal rotor motor due to increased air gap losses.

5. Cost: The cost of converting a motor can be significant, especially if specialized components or custom designs are required.

Advantages and Disadvantages

Both internal and external rotor motors have their advantages and disadvantages. Here are some key points to consider:

* Internal Rotor Motors:

* Advantages: Smaller size, higher efficiency, simpler construction.

* Disadvantages: Limited torque capabilities, less flexibility in terms of design and application.

* External Rotor Motors:

* Advantages: Higher torque capabilities, more flexibility in terms of design and application.

* Disadvantages: Larger size, lower efficiency due to increased air gap losses.

Conclusion

In conclusion, converting an internal rotor motor into an external rotor one and vice versa is possible but not straightforward. It requires significant modifications to the motor's design and components, which can be costly and time-consuming. Moreover, the performance of the converted motor may not meet the original specifications or expectations. Therefore, it is essential to carefully evaluate the benefits and drawbacks of such a conversion before proceeding.