Motor Application

How do I choose the right drive motor for my application ?

When selecting a drive motor for your application, considerWhen selecting a drive motor for your application, considerrque and speed, power duty cycle, cost, size, control compatibility, safety compliance, maintenance, and manufacturer reputation. This comprehensive guide helps ensure you choose a motor that meets your needs effectively and efficiently.

How can I choose the right combination motor drive for my application ?

When selecting a combination motor drive for your application, consider factors such as the type of motor (AC, DC, stepper, or servo), application requirements (load characteristics, speed and torque needs, control precision), appropriate drive technology (VFDs, electronic speed controls, stepper motor drives, servo amplifiers), compatibility and integration with existing systems, performance features (efficiency, dynamic response, protection features), budget and cost considerations (initial and operating costs), and seek professional advice from manufacturers and technical support.

What are the key factors to consider when selecting a permanent magnet motor for a specific application ?

When selecting a permanent magnet motor for a specific application, several key factors must be considered to ensure optimal performance and efficiency. These factors include application requirements, efficiency and performance, size and weight, temperature range and cooling, control and feedback systems, cost and budget, reliability and durability, and compatibility with other system components. By carefully considering these key factors when selecting a permanent magnet motor for your specific application, you can ensure that you choose a motor that meets your needs in terms of performance, efficiency, size, cooling requirements, control options, cost, reliability, and compatibility with other system components.

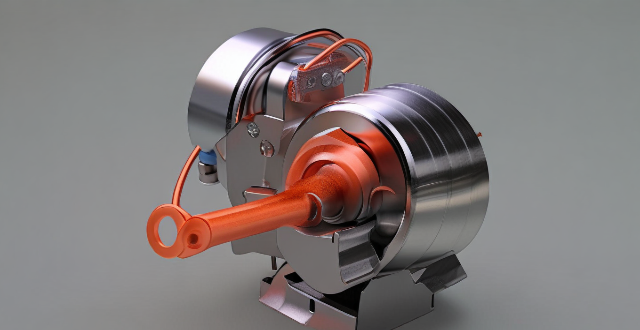

What is the efficiency rate of an internal rotor motor compared to other types of motors ?

The efficiency rate of an internal rotor motor compared to other types of motors depends on various factors such as design, size, application, materials, and control system. Internal rotor motors typically have higher efficiency rates than external rotor motors due to their compact design and reduced air gap between the rotor and stator. However, it is essential to consider the specific requirements of the application when choosing a motor type, as other factors such as brushless DC (BLDC) motors and permanent magnet synchronous motors (PMSM) are also known for their high efficiency rates.

What is the difference between single motor and multi-motor drives ?

Single motor drives control only one motor and are simple, cost-effective, and easy to maintain. Multi-motor drives control multiple motors simultaneously and offer increased flexibility, improved performance, and enhanced functionality but are more complex and expensive. The choice between these two types of drives depends on the specific requirements of the application.

What are the different types of combination motor drives available in the market ?

The article discusses different types of combination motor drives, including AC, DC, servo, and stepper motor drives. It highlights their unique features such as precise speed control, high torque output, regenerative braking, position control, feedback systems, and microstepping capabilities. The article emphasizes the importance of selecting the appropriate type of motor drive based on the specific needs and requirements of the application.

Is it possible to upgrade a machine to a single motor drive ?

The text discusses the possibility of upgrading a machine to a single motor drive. It outlines key considerations such as compatibility, performance requirements, and cost considerations. It also provides steps for upgrading to a single motor drive, including evaluating the machine, selecting a suitable motor drive, modifying the machine, installing the motor drive, and testing and optimizing the machine.

How do you choose the right AC stepping motor for your project ?

Choosing the right AC stepping motor requires understanding project needs, selecting the appropriate motor type, ensuring compatibility with control systems, considering physical constraints, evaluating performance characteristics, accounting for environmental factors, managing budgetary considerations, relying on supplier support and reputation, and conducting thorough testing.

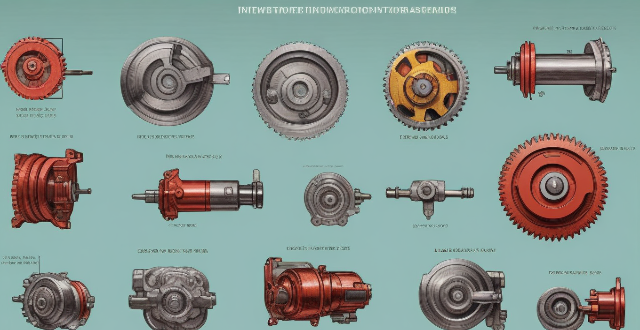

Can you explain the differences between an internal and external rotor motor ?

Motors are crucial components of various mechanical systems, and understanding their types is essential for selecting the appropriate one for a specific application. Two common types of motors are internal rotor motors and external rotor motors. An internal rotor motor has its rotor located inside the stator, while an external rotor motor has its rotor located outside the stator. The main differences between these two types of motors include rotor location, torque output, cooling efficiency, maintenance accessibility, and application suitability. Understanding these differences can help in selecting the appropriate motor type for a given task.

Is it possible to convert an internal rotor motor into an external rotor one, and vice versa ?

Converting an internal rotor motor into an external rotor one and vice versa is possible but not straightforward. It requires significant modifications to the motor's design and components, which can be costly and time-consuming. Moreover, the performance of the converted motor may not meet the original specifications or expectations. Therefore, it is essential to carefully evaluate the benefits and drawbacks of such a conversion before proceeding.

What are the key parameters to consider when selecting an AC stepping motor ?

Selecting an AC stepping motor involves considering key parameters such as torque, step angle, voltage and current ratings, resolution, size and weight, compatibility with the control system, and cost. These factors ensure the motor meets the application's requirements, providing enough rotational force, handling load demands, fitting within space and weight restrictions, and operating smoothly and precisely. Compatibility with the controller is crucial for proper operation, while cost considerations help stay within budget constraints.

Can an AC stepping motor be used in robotics applications ?

AC stepping motors can be used in robotics applications, offering precise control and high torque. However, they have speed limitations and can overheat, requiring cooling mechanisms. Consider application requirements and compatibility with control systems before choosing an AC stepping motor for a robotic project.

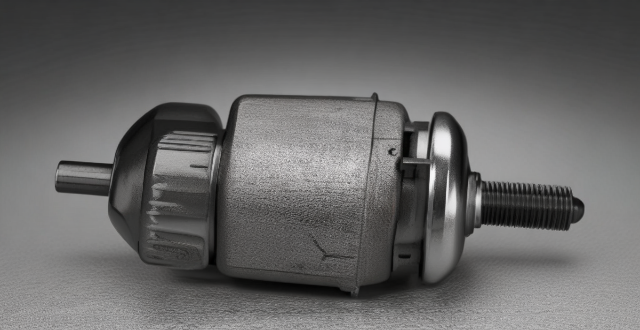

How does a DC brushed motor compare to a DC brushless motor in terms of efficiency and performance ?

The text provides a comparison between DC Brushed Motor and DC Brushless Motor in terms of efficiency, performance, and lifespan. DC brushed motors have lower efficiency due to energy loss caused by friction between the brushes and the commutator, while DC brushless motors are more efficient as there are no brushes to cause friction. In terms of performance, DC brushed motors are limited due to physical limitations of the brushes and commutator, while DC brushless motors offer improved performance with higher RPM and power output. Overall, a DC brushless motor is generally superior to a DC brushed motor in terms of efficiency, performance, and lifespan.

What are the advantages and disadvantages of using a DC brushed motor in robotics ?

DC brushed motors in robotics offer advantages such as affordability, simple maintenance, and high-speed efficiency. They provide predictable behavior and quick response to voltage changes, making them suitable for tasks requiring fast movements. However, they also present disadvantages including limited lifespan due to commutator wear, overheating issues, reduced torque at low speeds, electrical noise leading to EMI/RFI, higher power consumption, and potential size and weight constraints. The decision to use a brushed or brushless motor depends on the specific requirements of the robotic application.

How does a single motor drive compare to a dual motor drive ?

This article compares single motor drives and dual motor drives based on their performance, efficiency, cost, and applications. Single motor drives can only control one motor at a time, while dual motor drives can control two motors simultaneously. Dual motor drives offer higher overall torque and better synchronization between multiple motors, but they also consume more power and require more maintenance. Single motor drives are typically less expensive and well-suited for low power applications with simple movement profiles, while dual motor drives are appropriate for high power applications with complex movement profiles requiring precise synchronization. The choice between a single motor drive and a dual motor drive depends on the specific requirements of the application.

What is the typical cost difference between a permanent magnet motor and an equivalent size induction motor ?

Permanent magnet motors (PMMs) and induction motors (IMs) are two common types of electric motors used in various applications. The cost difference between them is often a significant factor in deciding which one to use. PMMs are known for their high efficiency, compact size, and low noise levels, while IMs are simpler and more robust. The cost difference depends on factors such as size, power rating, materials used, and manufacturing processes. Generally, PMMs are more expensive than IMs of equivalent size due to material costs, manufacturing processes, efficiency and performance requirements, and market demand and availability. When choosing between these two types of motors, it is essential to consider both the technical requirements and budget constraints of your specific application.

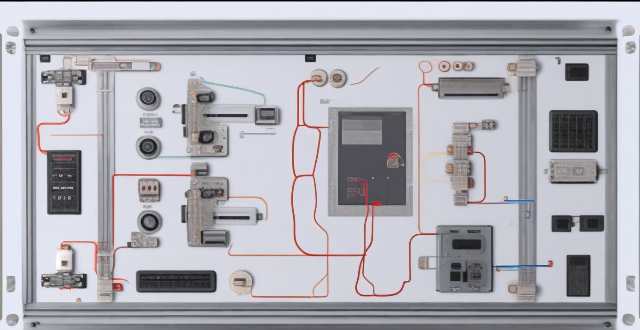

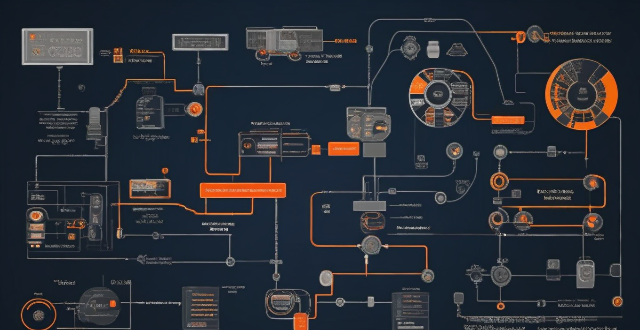

How does a combination motor drive work ?

Combination motor drives integrate VFD and servo controller functionalities to achieve precise speed and torque control for AC induction and permanent magnet synchronous motors. They enhance performance, reduce energy consumption, and extend motor lifespan by offering smooth speed control and reducing wear and tear. Key components include a VFD, servo controller, electric motor, encoder, and user interface. The system uses feedback from an encoder to adjust the motor's input signals, ensuring accurate motion profiles.

Can a speed controller be used to control the speed of an electric motor ?

A speed controller is a device that adjusts the electrical power supplied to an electric motor to change its speed. There are several types of speed controllers available for electric motors, including variable frequency drives (VFDs), DC motor controllers, and phase controllers. Using a speed controller has benefits such as energy efficiency, improved performance, extended motor lifespan, and enhanced safety.

How does a single motor drive work ?

The motor drive converts incoming AC power to DC, controls the motor's speed via PWM, regulates its torque by monitoring current and adjusting voltage, and ensures proper operation through feedback control.

How do you maintain and care for a permanent magnet motor to extend its lifespan ?

Permanent magnet motors are widely used in various industries due to their high efficiency, power density, and reliability. However, proper maintenance and care are essential to extend the lifespan of these motors. Here are some tips on how to maintain and care for a permanent magnet motor: - Regular cleaning, lubrication, thermal management, electrical maintenance, mechanical maintenance, environmental considerations, and preventive maintenance schedule are all important aspects of maintaining a permanent magnet motor. - External and internal cleaning should be done regularly to keep the motor clean from dust, dirt, and debris. Lubrication of bearings and gearbox (if any) should be done according to the manufacturer's recommendations. - Thermal management includes ensuring that the cooling system is functioning properly and monitoring the temperature of the motor during operation. Overheating can cause damage to the magnets and other components. - Electrical maintenance involves checking all electrical connections periodically to ensure they are secure and free from corrosion. Insulation resistance should also be tested periodically to detect any potential issues before they become serious problems. - Mechanical maintenance includes ensuring that the motor shaft is properly aligned with the load and performing vibration analysis periodically to identify any mechanical issues such as imbalance or loose parts. - Environmental considerations involve storing and operating the motor in a dry environment to prevent rust and corrosion. Protection from harsh environmental conditions such as extreme temperatures, chemicals, or moisture should also be considered. - A preventive maintenance schedule should be created based on the manufacturer's recommendations and specific application requirements. Regular inspections and prompt attention to any issues will save time and money in the long run by preventing more significant problems from occurring.

How much power can a hub motor generate ?

Hub motors are electric motors built into the wheel's hub and are commonly found in electric vehicles, wheelchairs, and other space-limited applications. The power generation of a hub motor is influenced by its design, size, and the type of battery it uses. Larger motors generally produce more power but require more energy to operate. The control system managing the motor's power output can also affect performance. Examples of hub motor power generation include small electric bikes (250-500 watts), medium electric bikes (500-1000 watts), large electric bikes (over 1000 watts), electric wheelchairs (250-1000 watts), and other applications like golf carts and electric cars with varying power ratings.

Are permanent magnet motors more susceptible to damage from high temperatures compared to other motor types ?

Permanent magnet motors are more susceptible to high temperatures due to demagnetization and thermal expansion issues, compared to induction motors and switched reluctance motors which primarily face insulation degradation and material fatigue respectively.

What is a hub motor ?

A hub motor is an electric motor integrated into a vehicle's wheel hub, offering direct drive, simplified design, quiet operation, and space efficiency. However, it has limitations such as limited power output, overheating concerns, and cost considerations. Hub motors are commonly used in electric vehicles like bicycles, scooters, motorcycles, and cars.

How does a co-signer affect my mortgage application ?

A co-signer is a person who signs a loan application along with the primary borrower. The co-signer agrees to take on the responsibility of repaying the loan if the primary borrower fails to do so. In this article, we will discuss how a co-signer affects your mortgage application. The credit score of both the primary borrower and the co-signer plays a significant role in determining the eligibility for a mortgage loan. A co-signer with a good credit score can improve the chances of getting approved for a mortgage loan. However, if the co-signer has a poor credit score, it may negatively impact the loan approval process. The income and debt-to-income ratio (DTI) of both the primary borrower and the co-signer are also important factors that lenders consider when evaluating a mortgage application. If the co-signer has a high income and low DTI, it can help strengthen the application and increase the chances of approval. On the other hand, if the co-signer has a low income or high DTI, it may negatively impact the loan approval process. Lenders also consider the employment history of both the primary borrower and the co-signer when evaluating a mortgage application. A stable employment history can demonstrate financial stability and reliability, which can positively impact the loan approval process. If the co-signer has a stable employment history, it can help strengthen the application and increase the chances of approval. The assets and liabilities of both the primary borrower and the co-signer are also taken into consideration by lenders when evaluating a mortgage application. If the co-signer has significant assets and few liabilities, it can help strengthen the application and increase the chances of approval. However, if the co-signer has significant liabilities or limited assets, it may negatively impact the loan approval process. In conclusion, a co-signer can have a significant impact on your mortgage application. Their credit score, income and DTI, employment history, assets, and liabilities are all factors that lenders consider when evaluating a mortgage application. It is important to choose a co-signer who has a good credit score, stable employment history, and low DTI to increase the chances of getting approved for a mortgage loan.

What are the advantages of using an AC stepping motor compared to a DC stepping motor ?

The text discusses the advantages of using AC stepping motors compared to DC stepping motors. The main points include: 1. **Simplified Drive Circuitry**: AC stepping motors have simpler drive circuitry than DC stepping motors, leading to fewer components and a more streamlined design, which reduces complexity and lowers manufacturing costs. 2. **Higher Torque Output**: AC stepping motors typically offer higher torque output than DC stepping motors, making them ideal for applications requiring high torque at low speeds. This also leads to improved efficiency and reduced energy consumption. 3. **Better Heat Dissipation**: AC stepping motors often have better heat dissipation capabilities due to their larger surface area and improved cooling mechanisms, allowing them to operate at higher temperatures without overheating and extending their lifespan. 4. **Compatibility with Standard AC Power Sources**: AC stepping motors are compatible with standard AC power sources widely available in industrial and commercial settings, eliminating the need for additional power supplies or conversion equipment and simplifying installation. 5. **Lower Maintenance Requirements**: AC stepping motors generally require less maintenance than DC stepping motors, as they have fewer moving parts and simpler drive circuitry, reducing maintenance costs and downtime. Overall, the text highlights that AC stepping motors offer significant benefits over DC stepping motors in terms of simplicity, performance, efficiency, compatibility, and maintenance, making them a popular choice for various applications where precision control and reliability are essential.

What is the difference between a bipolar and unipolar AC stepping motor ?

AC stepping motors are widely used in various applications such as robotics, CNC machines, and automation systems. They convert electrical pulses into mechanical movements with high precision and repeatability. There are two main types of AC stepping motors: bipolar and unipolar. This article will discuss the differences between these two types of motors. Bipolar AC stepping motors have two windings that are connected in series or parallel. Each winding is energized by an alternating current (AC) source, which creates a magnetic field. The direction of the magnetic field depends on the polarity of the current flowing through the windings. By changing the polarity of the current flowing through the windings, the direction of rotation can be reversed. Bipolar AC stepping motors have several advantages over unipolar motors, including higher torque output at lower speeds, better heat dissipation due to larger surface area of the windings, and more efficient use of electrical energy due to lower resistance of the windings. Unipolar AC stepping motors have only one winding that is energized by an alternating current (AC) source. The direction of the magnetic field created by this winding is always the same, regardless of the polarity of the current flowing through it. Unlike bipolar motors, unipolar motors cannot change the direction of rotation without additional hardware. Unipolar AC stepping motors have some advantages over bipolar motors, including simpler control circuitry since only one winding needs to be controlled, lower cost due to fewer components required for operation, and smaller size and weight, making them suitable for compact applications. In conclusion, bipolar and unipolar AC stepping motors differ in terms of their number of windings, ability to reverse direction, torque output, heat dissipation, efficiency, control circuitry complexity, cost, and size/weight. Depending on the specific requirements of your application, you may choose either type of motor based on these factors.

How does the design of a DC brushed motor impact its performance and efficiency ?

The performance and efficiency of a DC brushed motor are significantly influenced by its design. Key factors include the materials used, winding configuration, magnet strength, bearing type, and cooling system. Materials such as silicon steel for stator cores and carbon steel or aluminum alloys for rotor cores affect magnetic properties and mechanical strength. Winding configuration, including the number of poles and winding type (lap or wave), determines speed and torque characteristics. Magnet strength, shape, and placement impact torque production and power density. Bearing type (ball or roller) affects precision, friction, and load capacity. Finally, proper cooling through active or passive methods is essential for preventing overheating during operation. Overall, careful consideration of these design elements is crucial for achieving desired motor performance and efficiency goals.

How can I check the status of my tourist visa application ?

Checking the status of your tourist visa application can be a nerve-wracking experience, especially when you're eagerly anticipating your travel plans. Here's a step-by-step guide to help you through the process: 1. Determine the type of visa you applied for, as different visas might have different checking procedures. 2. Locate the appropriate government website or portal dedicated to visa services where you can check the status of your application. 3. Have your application details ready, such as Application ID Number, Passport Number, and Date of Birth. 4. Enter the required details into the online system on the visa status portal. 5. Submit the form and retrieve the status of your visa application. 6. Interpret the status message, which could indicate that your application has been accepted, is under review, requires administrative processing, has been issued, or has been refused. 7. Follow up if necessary with the embassy or consulate for any delays or further action required. Additional tips include keeping track of timelines, being patient as visa processing times can vary, and staying informed about any events that might affect processing times. By following these steps, you should be able to effectively check the status of your tourist visa application and plan accordingly.

Can you provide some examples of applications where multi-motor drives are used ?

Multi-motor drives are used in various applications where multiple motors need to be controlled simultaneously, including industrial automation, CNC machines, electric vehicles, wind turbines, robotics, and aerospace.

Can a combination motor drive improve energy efficiency in my facility ?

Combination motor drives can improve energy efficiency in facilities by optimizing electric motor performance, reducing energy consumption, and extending equipment lifespan. They offer variable speed control, soft start/stop capabilities, and reactive power compensation features that contribute to lower energy bills, reduced maintenance costs, and environmental benefits like reduced greenhouse gas emissions.