The efficiency rate of an internal rotor motor compared to other types of motors depends on various factors such as design, size, application, materials, and control system. Internal rotor motors typically have higher efficiency rates than external rotor motors due to their compact design and reduced air gap between the rotor and stator. However, it is essential to consider the specific requirements of the application when choosing a motor type, as other factors such as brushless DC (BLDC) motors and permanent magnet synchronous motors (PMSM) are also known for their high efficiency rates.

Efficiency Rate of an Internal Rotor Motor Compared to Other Types of Motors

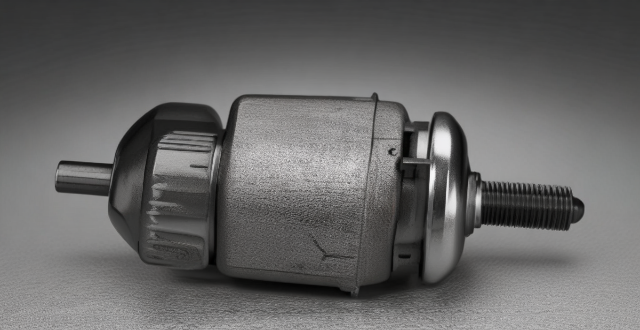

An internal rotor motor is a type of electric motor where the rotor is located inside the stator. The efficiency rate of an internal rotor motor compared to other types of motors depends on various factors such as the design, size, and application. In general, internal rotor motors have higher efficiency rates than external rotor motors due to their compact design and reduced air gap between the rotor and stator.

Factors Affecting Efficiency Rate

1. Design: The design of the motor plays a crucial role in determining its efficiency rate. Internal rotor motors typically have a more compact design, which reduces energy losses and increases efficiency.

2. Size: The size of the motor also affects its efficiency rate. Smaller motors tend to have higher efficiency rates than larger ones due to lower energy losses.

3. Application: The application for which the motor is used can also impact its efficiency rate. For example, a motor used in a high-speed application may have a lower efficiency rate than one used in a low-speed application.

4. Materials: The materials used in the construction of the motor can also affect its efficiency rate. For instance, using high-quality materials such as copper wires and steel laminations can improve the motor's performance and efficiency.

5. Control System: The control system used to operate the motor can also influence its efficiency rate. Advanced control systems can optimize the motor's performance and reduce energy losses, leading to higher efficiency rates.

Comparison with Other Types of Motors

When comparing the efficiency rate of an internal rotor motor to other types of motors, it is essential to consider the specific application and operating conditions. However, in general, internal rotor motors tend to have higher efficiency rates than external rotor motors due to their compact design and reduced air gap between the rotor and stator. Additionally, brushless DC (BLDC) motors and permanent magnet synchronous motors (PMSM) are known for their high efficiency rates, making them suitable for applications requiring high torque and low energy consumption.

In conclusion, the efficiency rate of an internal rotor motor compared to other types of motors depends on various factors such as design, size, application, materials, and control system. While internal rotor motors generally have higher efficiency rates than external rotor motors, it is essential to consider the specific requirements of the application when choosing a motor type.