Motor Pack

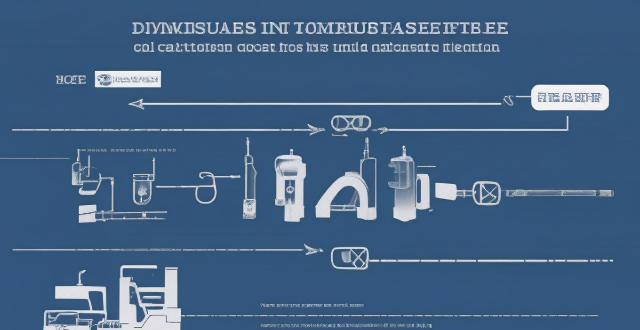

How does a Series Hybrid Electric Vehicle work ?

A series hybrid electric vehicle (SHEV) is a type of hybrid car that utilizes two power sources: an internal combustion engine (ICE) and an electric motor. The ICE generates electricity to charge the battery pack, which in turn powers the electric motor to propel the vehicle. The main components of a series hybrid electric vehicle include the ICE, battery pack, and electric motor. The working process of a series hybrid electric vehicle involves starting the vehicle with the electric motor drawing power from the battery pack, driving at low speeds or during city driving using only the electric motor, increasing speed or accelerating by starting up the ICE to generate electricity and charge the battery pack, regenerative braking to convert kinetic energy into electrical energy and store it in the battery pack, charging the battery pack when its state of charge falls below a certain level, steady-state driving on highways with the ICE running at its optimal speed while the electric motor provides necessary power, and shutting down both the ICE and electric motor when the vehicle is turned off. Series hybrid electric vehicles offer benefits such as improved fuel efficiency, lower emissions, reduced wear and tear on the ICE, and regenerative braking.

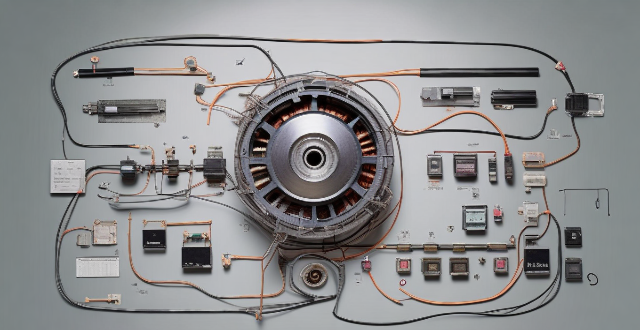

How does a multi-motor drive system work ?

The text explains how a multi-motor drive system works, its components, and benefits. It describes the process of power conversion, control signals, motor operation, mechanical transmission, and feedback adjustment in such systems. The advantages include improved efficiency, increased redundancy, and enhanced control.

What is a Series Hybrid Electric Vehicle (SHEV) ?

A Series Hybrid Electric Vehicle (SHEV) is a type of hybrid vehicle that uses an internal combustion engine and an electric motor to power the wheels. The engine generates electricity to charge the battery pack or provide power to the electric motor, which then drives the wheels. Some SHEVs have regenerative braking systems that capture energy during braking and use it to recharge the battery pack. Advantages of a SHEV include improved fuel economy, reduced emissions, increased torque, and quiet operation. Disadvantages include complexity, weight, limited range, and higher cost.

What should I pack for a cultural exploration journey ?

When embarking on a cultural exploration journey, itWhen embarking on a cultural exploration journey, it that will enhance your experience and it is important to pack items that will enhance your experience and ensure your comfort throughout the trip. Essential items include comfortable walking shoes, lightweight clothing, culturally appropriate attire, camera, portable charger, travel adapter, sunscreen, insect repellent, basic toiletries, reusable water bottle, daypack, and travel journal. Research the specific needs and customs of the culture you will be visiting to tailor your packing list accordingly.

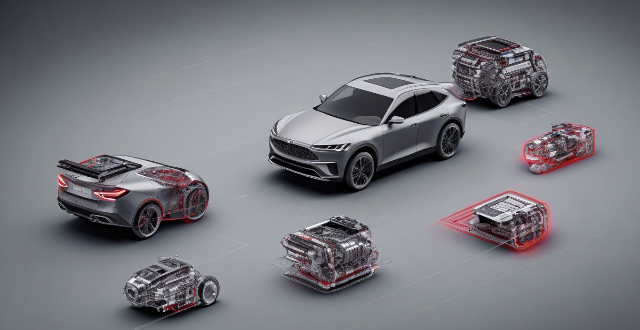

What are the key components of a Series Hybrid Electric Vehicle ?

Key components of a series hybrid electric vehicle (SHEV) include the battery pack, electric motor, internal combustion engine (ICE), generator, transmission, control unit, and regenerative braking system. The battery pack stores energy from the ICE or regenerative braking system and provides it to the electric motor when needed. The electric motor drives the wheels of the vehicle, while the ICE generates electricity to charge the battery pack rather than directly powering the wheels. The generator converts mechanical energy from the ICE into electrical energy to charge the battery pack. The transmission transfers power from the electric motor to the wheels using a single-speed reduction gearbox. The control unit manages the flow of energy between the various components and optimizes their operation. Finally, the regenerative braking system captures energy lost during braking and uses it to recharge the battery pack, increasing fuel efficiency and extending the range of the vehicle.

What are the advantages and disadvantages of multi-motor drives in electric vehicles ?

Multi-motor drives in electric vehicles provide enhanced performance, efficiency, redundancy, and design flexibility. However, they also come with increased complexity, cost, battery drain, weight, space constraints, and control challenges. The decision to use a multi-motor system should consider these factors based on the vehicle's goals and requirements.

What are the essential items to pack for a backpacking trip across Europe ?

When backpacking across Europe, it's crucial to pack essential items that cater to your needs during the journey. These include versatile and lightweight clothing, comfortable shoes, warm layers, basic toiletries, sun protection, a first aid kit, a well-fitted backpack, a sleeping bag, a headlamp or flashlight, power bank and chargers, a travel adapter, a camera, travel documents and money, a reusable water bottle, a daypack, a travel journal and pen, and a lock. Packing light is key for an enjoyable trip.

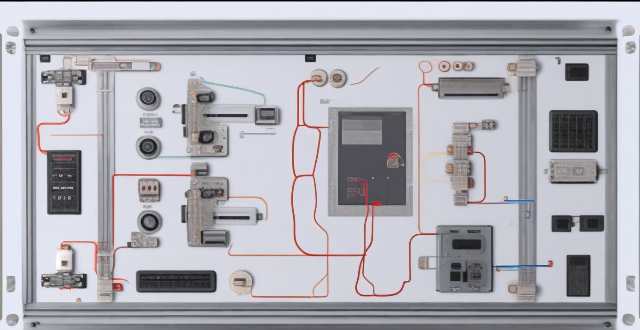

How does a single motor drive work ?

The motor drive converts incoming AC power to DC, controls the motor's speed via PWM, regulates its torque by monitoring current and adjusting voltage, and ensures proper operation through feedback control.

What should I pack for an adventure travel activity ?

Adventure travel activities can be thrilling and exciting, but it's important to pack the right gear to ensure your safety and comfort. Here are some essential items to consider packing for your next adventure: - Clothing: A waterproof jacket with a high waterproof rating and breathability is essential for outdoor activities in wet conditions. Quick-dry shirts and pants that are comfortable to move in and suitable for the climate you'll be traveling in are ideal. Comfortable shoes or boots that provide support, traction, and comfort are also important. Pack warm layers like a fleece jacket or sweater for cooler temperatures. - Gear: Choose a backpack that's comfortable to wear and has enough space for all your gear. A headlamp or flashlight is essential for navigating in the dark or during power outages. Pack extra batteries or a charger to ensure you have enough light throughout your trip. A well-stocked first aid kit with bandages, antiseptic wipes, pain relievers, and any prescription medications you may need is important. A multi-tool can come in handy for various tasks. - Other Essentials: A reusable water bottle and a water filter or purification tablets are crucial for staying hydrated. High-energy snacks and food that are easy to carry and won't spoil quickly are great options for fueling up during your adventure. Reliable navigation tools like a map, compass, or GPS device are essential for finding your way in unfamiliar terrain. By packing these essential items, you'll be prepared for whatever challenges come your way during your adventure travel activity. Remember to also check the weather forecast and any specific requirements for your destination to ensure you have everything you need for a safe and enjoyable trip.

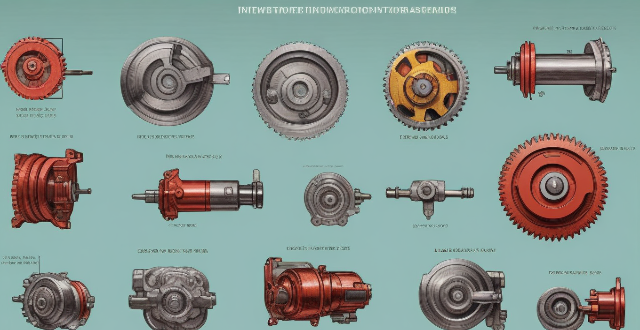

What is the difference between single motor and multi-motor drives ?

Single motor drives control only one motor and are simple, cost-effective, and easy to maintain. Multi-motor drives control multiple motors simultaneously and offer increased flexibility, improved performance, and enhanced functionality but are more complex and expensive. The choice between these two types of drives depends on the specific requirements of the application.

What is a hub motor ?

A hub motor is an electric motor integrated into a vehicle's wheel hub, offering direct drive, simplified design, quiet operation, and space efficiency. However, it has limitations such as limited power output, overheating concerns, and cost considerations. Hub motors are commonly used in electric vehicles like bicycles, scooters, motorcycles, and cars.

What are the key components of a CHEV's drive system ?

The key components of a CHEV's drive system include the engine, electric motor, transmission, battery pack, and energy management system. The engine generates the majority of the power needed to propel the vehicle, while the electric motor provides additional power during acceleration or hill climbing. The transmission transfers power from the engine and electric motor to the wheels, and may be a conventional automatic or manual transmission or a specialized hybrid transmission. The battery pack stores electrical energy generated by the electric motor during regenerative braking and provides power to the electric motor when needed. The energy management system controls the flow of energy between the engine, electric motor, and battery pack, determining when to use each source of power based on driving conditions, state of charge of the battery, and driver demand. These components work together to provide a seamless driving experience while maximizing fuel efficiency and reducing emissions.

How do you choose the right AC stepping motor for your project ?

Choosing the right AC stepping motor requires understanding project needs, selecting the appropriate motor type, ensuring compatibility with control systems, considering physical constraints, evaluating performance characteristics, accounting for environmental factors, managing budgetary considerations, relying on supplier support and reputation, and conducting thorough testing.

What kind of clothing should I pack for a trip to Africa ?

When packing for a trip to Africa, it's important to consider the climate and culture of the region you'll be visiting. Here are some essential clothing items to pack: - Lightweight and breathable fabrics such as cotton, linen, and rayon. - Long sleeve shirts and pants to protect your skin from the sun and insects. - A wide-brimmed hat to shade your face and neck. - Comfortable walking shoes or sandals with good support. - A light jacket or sweater for cooler evenings. - Sunglasses and sunscreen with high SPF protection. - Insect repellent to keep mosquitoes and other bugs at bay. It's also important to dress respectfully when traveling in Africa. Many African countries have conservative dress codes, especially in rural areas. Here are some tips to keep in mind: * Avoid wearing revealing or tight-fitting clothing. * Cover your shoulders and knees when visiting religious sites or conservative communities. * Women may want to bring a scarf or pashmina to cover their hair in certain situations. * Avoid wearing excessive amounts of jewelry or expensive accessories, as this can attract unwanted attention. The climate in Africa varies widely depending on the region and season. Here are some general guidelines for different seasons: Dry Season (November to April): * Lightweight clothing made of natural fibers like cotton and linen. * Shorts, skirts, and t-shirts for hot weather. * A light jacket or sweater for cooler evenings. * Sunglasses and sunscreen with high SPF protection. Wet Season (May to October): * Waterproof jacket or raincoat. * Quick-drying clothes that can be easily washed and dried. * Warm layers for cooler temperatures, especially in the evenings. * Insect repellent to keep mosquitoes and other bugs at bay. Year-Round Tips: * Pack clothing in neutral colors that can be mixed and matched easily. * Bring comfortable walking shoes or sandals with good support. * Don't forget a swimsuit if you plan on going to the beach or taking part in water activities. * Pack a small first aid kit with basic supplies like bandages, antiseptic wipes, and pain relievers.

Can you provide some examples of applications where multi-motor drives are used ?

Multi-motor drives are used in various applications where multiple motors need to be controlled simultaneously, including industrial automation, CNC machines, electric vehicles, wind turbines, robotics, and aerospace.

How does a parallel hybrid electric vehicle (PHEV) work ?

Parallel hybrid electric vehicles (PHEVs) are a type of hybrid vehicle that combines an internal combustion engine (ICE) with an electric motor. The two power sources can work independently or together, depending on the driving conditions. PHEVs have three operating modes: ICE only, electric motor only, and combined power. The energy management system controls the operation of the ICE and electric motor, deciding which power source to use based on driving conditions, battery state of charge, and other factors. PHEVs offer benefits such as improved fuel efficiency, reduced emissions, tax incentives, and reduced dependence on fossil fuels.

Can a combination motor drive improve energy efficiency in my facility ?

Combination motor drives can improve energy efficiency in facilities by optimizing electric motor performance, reducing energy consumption, and extending equipment lifespan. They offer variable speed control, soft start/stop capabilities, and reactive power compensation features that contribute to lower energy bills, reduced maintenance costs, and environmental benefits like reduced greenhouse gas emissions.

How does a single motor drive compare to a dual motor drive ?

This article compares single motor drives and dual motor drives based on their performance, efficiency, cost, and applications. Single motor drives can only control one motor at a time, while dual motor drives can control two motors simultaneously. Dual motor drives offer higher overall torque and better synchronization between multiple motors, but they also consume more power and require more maintenance. Single motor drives are typically less expensive and well-suited for low power applications with simple movement profiles, while dual motor drives are appropriate for high power applications with complex movement profiles requiring precise synchronization. The choice between a single motor drive and a dual motor drive depends on the specific requirements of the application.

How does a hybrid car work ?

A hybrid car uses a combination of an internal combustion engine and electric motors to achieve better fuel economy and reduced emissions. It consists of key components like the ICE, electric motor(s), battery pack, transmission, control unit, and a charging system that includes regenerative braking. The car operates in various modes: starting with the electric motor, driving with either or both power sources, using regenerative braking for efficiency and battery charging, minimizing idling by shutting down the ICE at stops, and managing the battery's state of charge and health. Benefits include improved gas mileage, lower emissions, enhanced performance, and reduced wear and tear on vehicle components.

What are the advantages and disadvantages of using a combination motor drive compared to a single motor drive ?

The combination motor drive has several advantages over a single motor drive, including improved performance, enhanced reliability, flexibility in design, energy efficiency, and modularity and scalability. However, it also has disadvantages such as complexity, cost, space requirements, synchronization issues, and integration challenges.

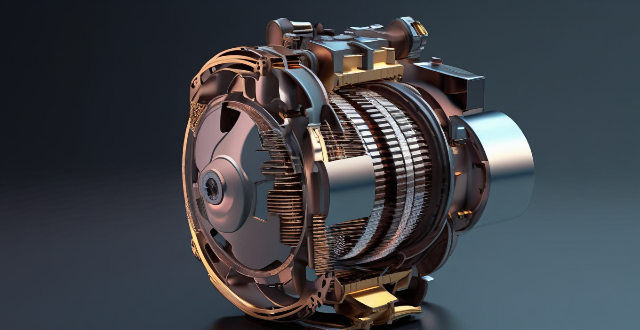

What is an internal rotor motor ?

The text discusses the design, advantages, disadvantages, and applications of internal rotor motors. Internal rotor motors are a type of electric motor where the moving part (rotor) is inside the stationary part (stator). They offer benefits such as high efficiency, good heat dissipation, simplicity in construction, and low inertia. However, they also have limitations like limited torque density, difficulty in cooling, and potential for magnetic saturation. These motors are commonly used in automotive, aerospace, industrial equipment, and consumer electronics applications.

How does the design of a permanent magnet motor differ from an induction motor ?

The article discusses the differences between permanent magnet motor and induction motor design, focusing on three main aspects: rotor design, stator winding design, and cooling system. The rotor of a permanent magnet motor contains high-energy rare-earth magnets that interact with the stator windings to produce torque, while the rotor of an induction motor has aluminum or copper bars that induce currents when exposed to a rotating magnetic field produced by the stator windings. The stator winding design also varies between the two types of motors, with permanent magnet motors typically having a three-phase distributed winding and induction motors having either a distributed or concentrated winding. Finally, the cooling system design differs as well, with permanent magnet motors often relying on natural convection or forced air cooling, while induction motors may use external fans or blowers for more effective heat removal. Understanding these differences is crucial for engineers to choose the appropriate motor type for their needs and optimize its performance accordingly.

How do you maintain and troubleshoot a DC brushed motor ?

Maintaining and Troubleshooting a DC Brushed Motor involves regular cleaning, lubrication, brush replacement, heat management, and monitoring voltage and current. Troubleshooting steps include checking for no power, reduced performance, excessive heat, vibration or noise, sparking, intermittent operation, and smoke or burning smell. Proper maintenance and troubleshooting can prolong the lifespan and ensure reliable operation of the motor.

How does a multi-motor drive system contribute to energy savings in industrial processes ?

A multi-motor drive system contributes to energy savings in industrial processes by optimizing the operation of multiple motors. It balances loads, controls speed optimally, provides reactive power compensation, enables regenerative braking, and reduces maintenance costs. This technology helps businesses improve their bottom line while reducing their environmental footprint.

What are the benefits of using a combination motor drive system ?

Combination motor drive systems offer benefits such as improved efficiency, increased reliability, flexibility, and enhanced control. These systems combine the advantages of different types of motors to create a more efficient and reliable drive system. They are ideal for a wide range of applications and can help businesses save money on energy costs while reducing downtime and maintenance requirements.

How do I choose the right drive motor for my application ?

When selecting a drive motor for your application, considerWhen selecting a drive motor for your application, considerrque and speed, power duty cycle, cost, size, control compatibility, safety compliance, maintenance, and manufacturer reputation. This comprehensive guide helps ensure you choose a motor that meets your needs effectively and efficiently.

What are the advantages of using a brushless motor ?

Brushless motors offer several advantages over traditional brushed motors, including higher efficiency, longer lifespan, improved performance, quieter operation, enhanced reliability, and environmental benefits. These benefits make them an attractive choice for a wide range of applications.

How does a combination motor drive work ?

Combination motor drives integrate VFD and servo controller functionalities to achieve precise speed and torque control for AC induction and permanent magnet synchronous motors. They enhance performance, reduce energy consumption, and extend motor lifespan by offering smooth speed control and reducing wear and tear. Key components include a VFD, servo controller, electric motor, encoder, and user interface. The system uses feedback from an encoder to adjust the motor's input signals, ensuring accurate motion profiles.

How does a brushless motor work ?

Brushless motors, also known as BLDC motors, are electric motors that use an electronic controller to switch the current in their stator windings. They consist of three main components: the rotor, stator, and electronic controller. The working principle of a brushless motor involves initial rotation, commutation, and maintaining rotation. Brushless motors offer several advantages over traditional brushed motors, including higher efficiency, longer lifespan, better performance, and lower maintenance.

Is it possible to convert an internal rotor motor into an external rotor one, and vice versa ?

Converting an internal rotor motor into an external rotor one and vice versa is possible but not straightforward. It requires significant modifications to the motor's design and components, which can be costly and time-consuming. Moreover, the performance of the converted motor may not meet the original specifications or expectations. Therefore, it is essential to carefully evaluate the benefits and drawbacks of such a conversion before proceeding.