Motor Longevity

How do I maintain my internal rotor motor to ensure its longevity ?

Maintaining an Internal Rotor Motor for Longevity involves regular cleaning, inspection, lubrication, and checks on critical components. Proper care can extend the motor's lifespan and prevent costly repairs. Cleaning includes removing dust and debris with a soft cloth and compressed air. Deep cleaning is recommended when there are signs of overheating or reduced performance. Inspections should check for visible damage, wear, insulation resistance, and tight connections. Lubricating moving parts and changing lubricants as needed is essential. Bearings should be checked for wear and replaced if necessary, while cooling systems should be inspected for blockages or leaks. Seal integrity should also be verified. Performance testing and preventive replacement of worn parts can save time and money in the long run. Environmental considerations such as keeping the motor in a clean, dry, and temperate environment should also be taken into account. By following these steps, optimal performance and longevity of the internal rotor motor can be ensured.

How does exercise influence aging and longevity ?

Exercise is crucial for maintaining good health and well-being, with numerous benefits including improved cardiovascular health and reduced risk of chronic diseases. It also has a significant impact on aging and longevity, as regular physical activity can help maintain muscle mass, improve bone density, and reduce the risk of chronic diseases. Exercise also has mental health benefits, such as improved cognitive function and reduced risk of depression and anxiety. Numerous studies have shown that exercise can lead to an increased lifespan by reducing the risk of premature death from various causes. Examples of long-lived populations, such as the Okinawans and Nicoyans, demonstrate the importance of an active lifestyle in promoting healthy aging and longevity. Incorporating exercise into your daily routine can lead to a higher quality of life during your golden years and potentially extend your lifespan.

What are the advantages of using a single motor drive system ?

A single motor drive system is a type of electric motor control system that uses only one motor to power a machine or equipment. This system has several advantages over other types of drive systems, including simplified design and maintenance, improved efficiency and performance, increased reliability and longevity, and greater flexibility and versatility. These benefits make it an attractive option for many industrial applications where precise control and efficient operation are essential.

How do I maintain and troubleshoot a drive motor ?

Maintaining and troubleshooting a drive motor is crucial for ensuring its longevity and optimal performance. Here are some tips on how to do it: ### Maintenance Tips 1. Keep the motor clean by removing dust, dirt, and debris from the exterior and interior components. This helps prevent overheating and damage to the motor. 2. Ensure that the motor bearings are properly lubricated to reduce friction and wear. Follow the manufacturer's recommendations for the type and frequency of lubrication. 3. Check the cooling system (if applicable) regularly to ensure it is functioning correctly. Clean or replace filters as needed to maintain proper airflow. 4. Inspect electrical connections for signs of corrosion, damage, or looseness. Tighten or replace connections as necessary to prevent electrical issues. 5. Monitor the voltage and amperage of the motor to ensure they are within the recommended range. Excessive voltage or amperage can cause damage to the motor. 6. Ensure that thermal protection devices are functioning correctly to prevent overheating and potential damage to the motor. 7. Conduct periodic inspections of the motor, including checking for unusual noises, vibrations, or smells. Address any issues promptly to avoid further damage. ### Troubleshooting Tips If you encounter issues with your drive motor, here are some troubleshooting steps to follow: 1. Ensure that the motor is receiving the correct voltage and amperage. A faulty power supply can cause the motor to malfunction or fail. 2. Check for loose, damaged, or corroded wiring connections. Repair or replace any faulty wiring to restore proper functionality. 3. If you hear unusual noises coming from the motor, such as grinding or humming, it could indicate a problem with the bearings or other internal components. Consult a professional mechanic for further diagnosis and repair. 4. If the motor is overheating, check the cooling system for any blockages or issues with airflow. Clean or replace filters as needed to improve cooling efficiency. 5. Test thermal protection devices to ensure they are functioning correctly. Faulty devices may not provide adequate protection against overheating, leading to motor damage. 6. If you are unable to identify or resolve the issue, consult the manufacturer's guide or contact their support team for assistance. They may be able to provide additional troubleshooting steps or recommend a professional mechanic for further inspection and repair. By following these maintenance and troubleshooting tips, you can help ensure the longevity and optimal performance of your drive motor. Remember to always prioritize safety when working on any machinery and seek professional assistance if necessary.

How do I maintain and care for my brushless motor ?

Taking care of your brushless motor is essential to ensure its longevity and performance. Here are some tips on how to maintain and care for your brushless motor: Regular Cleaning: - Clean the motor, heat sink, and propeller regularly to remove dirt, dust, or debris. Lubrication: - Lubricate the bearings with a high-quality lubricant to reduce friction and wear. - Avoid overlubrication as it can attract dirt and debris. Inspection: - Inspect the motor, wiring connections, and propeller for any signs of damage or corrosion. - Replace damaged components or the entire motor if necessary. Storage: - Store your brushless motor in a dry place to prevent moisture from entering the motor. - Avoid storing the motor in direct sunlight to prevent discoloration and damage to the components. Usage: - Avoid overloading the motor by using the appropriate propeller size and battery voltage. - Use a LiPo battery with an appropriate C rating for optimal performance. - Avoid exposing the motor to water as it can cause damage to the electronic components. By following these maintenance and care tips, you can ensure that your brushless motor performs at its best and lasts for a long time.

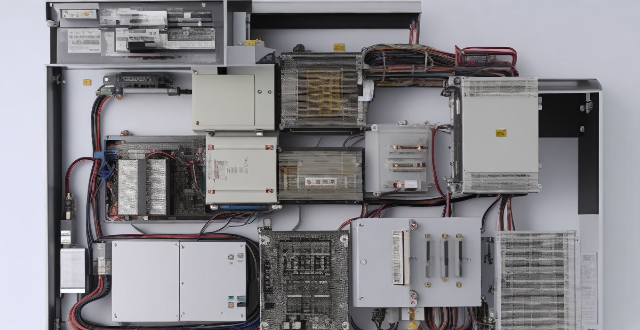

What are the maintenance requirements for a single motor drive system ?

Maintenance requirements for a single motor drive system include daily visual and auditory inspections, weekly lubrication and cleanliness checks, monthly electrical connection and belt tension inspections, quarterly cooling system cleaning and bearing lubrication, yearly motor performance testing and preventative replacement of parts, additional environmental factor considerations, and following manufacturer's guidelines for maintenance and servicing.

How do you control the speed and torque of an AC stepping motor ?

The text provides a comprehensive overview of controlling the speed and torque of an AC stepping motor, emphasizing the importance of understanding its basic principles and utilizing appropriate control techniques. Key points include the motor's working principle, torque generation, and step resolution, as well as various control methods such as pulse rate modulation, microstepping, closed-loop control, current limiting, voltage control, and soft start/stop. Practical considerations like drive system compatibility, thermal management, load factors, and safety precautions are also highlighted for optimal motor performance and longevity.

Can an AC stepping motor be used in robotics applications ?

AC stepping motors can be used in robotics applications, offering precise control and high torque. However, they have speed limitations and can overheat, requiring cooling mechanisms. Consider application requirements and compatibility with control systems before choosing an AC stepping motor for a robotic project.

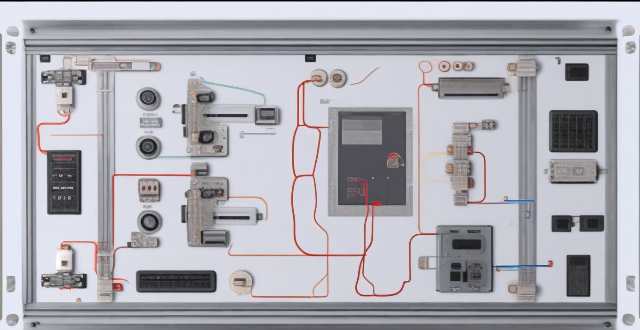

How does a single motor drive work ?

The motor drive converts incoming AC power to DC, controls the motor's speed via PWM, regulates its torque by monitoring current and adjusting voltage, and ensures proper operation through feedback control.

What is the difference between single motor and multi-motor drives ?

Single motor drives control only one motor and are simple, cost-effective, and easy to maintain. Multi-motor drives control multiple motors simultaneously and offer increased flexibility, improved performance, and enhanced functionality but are more complex and expensive. The choice between these two types of drives depends on the specific requirements of the application.

What is a hub motor ?

A hub motor is an electric motor integrated into a vehicle's wheel hub, offering direct drive, simplified design, quiet operation, and space efficiency. However, it has limitations such as limited power output, overheating concerns, and cost considerations. Hub motors are commonly used in electric vehicles like bicycles, scooters, motorcycles, and cars.

How do you choose the right AC stepping motor for your project ?

Choosing the right AC stepping motor requires understanding project needs, selecting the appropriate motor type, ensuring compatibility with control systems, considering physical constraints, evaluating performance characteristics, accounting for environmental factors, managing budgetary considerations, relying on supplier support and reputation, and conducting thorough testing.

Can you provide some examples of applications where multi-motor drives are used ?

Multi-motor drives are used in various applications where multiple motors need to be controlled simultaneously, including industrial automation, CNC machines, electric vehicles, wind turbines, robotics, and aerospace.

Can a combination motor drive improve energy efficiency in my facility ?

Combination motor drives can improve energy efficiency in facilities by optimizing electric motor performance, reducing energy consumption, and extending equipment lifespan. They offer variable speed control, soft start/stop capabilities, and reactive power compensation features that contribute to lower energy bills, reduced maintenance costs, and environmental benefits like reduced greenhouse gas emissions.

How does a single motor drive compare to a dual motor drive ?

This article compares single motor drives and dual motor drives based on their performance, efficiency, cost, and applications. Single motor drives can only control one motor at a time, while dual motor drives can control two motors simultaneously. Dual motor drives offer higher overall torque and better synchronization between multiple motors, but they also consume more power and require more maintenance. Single motor drives are typically less expensive and well-suited for low power applications with simple movement profiles, while dual motor drives are appropriate for high power applications with complex movement profiles requiring precise synchronization. The choice between a single motor drive and a dual motor drive depends on the specific requirements of the application.

How can I maintain and repair my electromagnetic motor ?

Maintaining and repairing an electromagnetic motor is vital for its longevity and efficient operation. This step-by-step guide covers regular maintenance, troubleshooting, repairs, and preventative measures to keep the motor in top condition. Regular maintenance includes cleaning, lubrication, and inspection of wiring, connections, and cooling systems. Troubleshooting involves diagnosing issues such as strange noises, reduced performance, and overheating. Common repairs include replacing worn parts, repairing or replacing wiring, and adjusting settings. Seeking professional help is recommended for complex issues, electrical safety concerns, and warranty work. Preventative measures include proper use, adequate ventilation, and environmental considerations. Following these guidelines ensures the motor's lifespan and efficiency while prioritizing safety during electrical equipment maintenance.

How does a multi-motor drive system work ?

The text explains how a multi-motor drive system works, its components, and benefits. It describes the process of power conversion, control signals, motor operation, mechanical transmission, and feedback adjustment in such systems. The advantages include improved efficiency, increased redundancy, and enhanced control.

What maintenance is required for a hybrid car ?

Maintaining a hybrid car involves regular checks on the battery health and cooling system, brake inspections, tire care, engine oil changes, coolant flushes, electric motor lubrication, transmission fluid checks, and adhering to scheduled services. Proper maintenance ensures the longevity of high-value components like the battery and electric motor, contributing to improved fuel economy and reduced emissions.

What are the advantages and disadvantages of using a combination motor drive compared to a single motor drive ?

The combination motor drive has several advantages over a single motor drive, including improved performance, enhanced reliability, flexibility in design, energy efficiency, and modularity and scalability. However, it also has disadvantages such as complexity, cost, space requirements, synchronization issues, and integration challenges.

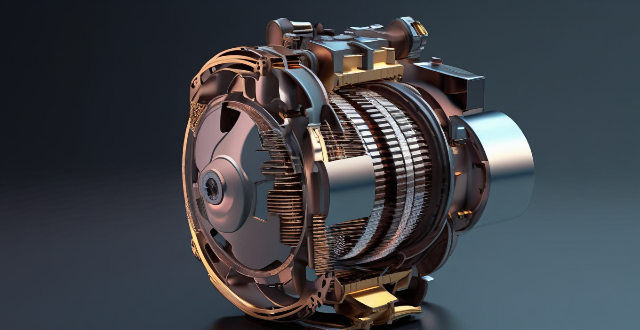

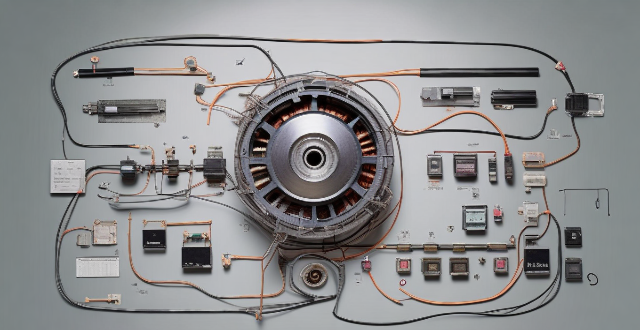

What is an internal rotor motor ?

The text discusses the design, advantages, disadvantages, and applications of internal rotor motors. Internal rotor motors are a type of electric motor where the moving part (rotor) is inside the stationary part (stator). They offer benefits such as high efficiency, good heat dissipation, simplicity in construction, and low inertia. However, they also have limitations like limited torque density, difficulty in cooling, and potential for magnetic saturation. These motors are commonly used in automotive, aerospace, industrial equipment, and consumer electronics applications.

How does the design of a permanent magnet motor differ from an induction motor ?

The article discusses the differences between permanent magnet motor and induction motor design, focusing on three main aspects: rotor design, stator winding design, and cooling system. The rotor of a permanent magnet motor contains high-energy rare-earth magnets that interact with the stator windings to produce torque, while the rotor of an induction motor has aluminum or copper bars that induce currents when exposed to a rotating magnetic field produced by the stator windings. The stator winding design also varies between the two types of motors, with permanent magnet motors typically having a three-phase distributed winding and induction motors having either a distributed or concentrated winding. Finally, the cooling system design differs as well, with permanent magnet motors often relying on natural convection or forced air cooling, while induction motors may use external fans or blowers for more effective heat removal. Understanding these differences is crucial for engineers to choose the appropriate motor type for their needs and optimize its performance accordingly.

How do you maintain and troubleshoot a DC brushed motor ?

Maintaining and Troubleshooting a DC Brushed Motor involves regular cleaning, lubrication, brush replacement, heat management, and monitoring voltage and current. Troubleshooting steps include checking for no power, reduced performance, excessive heat, vibration or noise, sparking, intermittent operation, and smoke or burning smell. Proper maintenance and troubleshooting can prolong the lifespan and ensure reliable operation of the motor.

How does a multi-motor drive system contribute to energy savings in industrial processes ?

A multi-motor drive system contributes to energy savings in industrial processes by optimizing the operation of multiple motors. It balances loads, controls speed optimally, provides reactive power compensation, enables regenerative braking, and reduces maintenance costs. This technology helps businesses improve their bottom line while reducing their environmental footprint.

How long do hub motors typically last ?

Hub motors are crucial for the performance and reliability of electric vehicles. The typical lifespan of hub motors is 50,000 to 100,000 miles or more, depending on various factors such as quality, usage, maintenance, and environmental conditions. Proper maintenance, avoiding overloading, proper storage, using quality accessories, and responsible driving can help extend the lifespan of hub motors.

What are the benefits of using a combination motor drive system ?

Combination motor drive systems offer benefits such as improved efficiency, increased reliability, flexibility, and enhanced control. These systems combine the advantages of different types of motors to create a more efficient and reliable drive system. They are ideal for a wide range of applications and can help businesses save money on energy costs while reducing downtime and maintenance requirements.

How do I choose the right drive motor for my application ?

When selecting a drive motor for your application, considerWhen selecting a drive motor for your application, considerrque and speed, power duty cycle, cost, size, control compatibility, safety compliance, maintenance, and manufacturer reputation. This comprehensive guide helps ensure you choose a motor that meets your needs effectively and efficiently.

What are the advantages of using a brushless motor ?

Brushless motors offer several advantages over traditional brushed motors, including higher efficiency, longer lifespan, improved performance, quieter operation, enhanced reliability, and environmental benefits. These benefits make them an attractive choice for a wide range of applications.

Are brushless motors more efficient than brushed motors ?

Brushless motors are more efficient than brushed motors due to their lack of friction, reduced maintenance requirements, higher RPM range, improved torque control, and better power-to-weight ratio.

How does a combination motor drive work ?

Combination motor drives integrate VFD and servo controller functionalities to achieve precise speed and torque control for AC induction and permanent magnet synchronous motors. They enhance performance, reduce energy consumption, and extend motor lifespan by offering smooth speed control and reducing wear and tear. Key components include a VFD, servo controller, electric motor, encoder, and user interface. The system uses feedback from an encoder to adjust the motor's input signals, ensuring accurate motion profiles.

How does a brushless motor work ?

Brushless motors, also known as BLDC motors, are electric motors that use an electronic controller to switch the current in their stator windings. They consist of three main components: the rotor, stator, and electronic controller. The working principle of a brushless motor involves initial rotation, commutation, and maintaining rotation. Brushless motors offer several advantages over traditional brushed motors, including higher efficiency, longer lifespan, better performance, and lower maintenance.