Motor Electronic

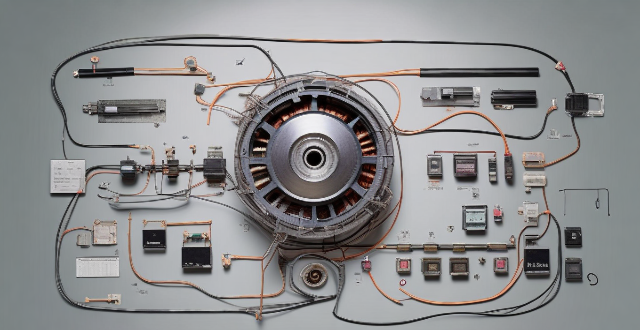

How does a brushless motor work ?

Brushless motors, also known as BLDC motors, are electric motors that use an electronic controller to switch the current in their stator windings. They consist of three main components: the rotor, stator, and electronic controller. The working principle of a brushless motor involves initial rotation, commutation, and maintaining rotation. Brushless motors offer several advantages over traditional brushed motors, including higher efficiency, longer lifespan, better performance, and lower maintenance.

What are the benefits of using an electronic speed controller ?

Benefits of Using an Electronic Speed Controller An electronic speed controller (ESC) regulates the speed of electric motors by controlling the amount of electrical power delivered to them. It is a crucial component in many electronic devices, particularly in the field of robotics and drones. The benefits of using an ESC include precision control over the motor's speed, increased efficiency by reducing energy consumption, improved safety by preventing damage to components, enhanced performance by allowing for more precise control over the motor's speed, and reduced maintenance costs. These benefits make ESCs essential components in many electronic devices and systems.

Is it possible to upgrade my existing mechanical speed controller to an electronic one ?

Mechanical speed controllers have been used for a long time in various applications, such as fans, pumps, and other machinery. However, with the advancement of technology, electronic speed controllers have become more popular due to their advantages over mechanical ones. In this article, we will discuss whether it is possible to upgrade your existing mechanical speed controller to an electronic one. The first factor to consider is compatibility. You need to ensure that the electronic speed controller is compatible with your existing motor and system. This may require consulting with a professional or the manufacturer of both the motor and the electronic speed controller. Another important factor is power requirements. You need to make sure that the electronic speed controller can handle the power output of your motor. If not, you may need to upgrade your motor as well. Installation is another crucial aspect to consider when upgrading from a mechanical to an electronic speed controller. This may require additional wiring and configuration changes, which should be done by a professional to ensure proper installation and operation. Finally, you need to consider the cost of upgrading. While electronic speed controllers offer many advantages, they can be more expensive than mechanical ones. You should weigh the initial cost against the potential long-term savings in energy consumption and maintenance costs before making a decision. In conclusion, it is possible to upgrade your existing mechanical speed controller to an electronic one, but several factors need to be considered before doing so. These include compatibility, power requirements, installation, and cost. By carefully evaluating these factors and consulting with professionals, you can determine if upgrading is the right choice for your application.

What is an electronic speed controller ?

The text provides an overview of electronic speed controllers (ESCs), which are devices used to regulate the power sent to motors in model aircraft and drones. It describes key features such as adjustable throttle, battery protection, signal modulation, and failsafe functionality. The process by which ESCs work is outlined: receiving a signal from the radio transmitter, decoding it into a throttle setting, controlling motor speed based on this setting, and providing feedback to the pilot. Two types of ESCs are mentioned: brushed and brushless, with the latter being more complex and expensive. The text concludes that ESCs are crucial for precise control over motor speed and aircraft performance.

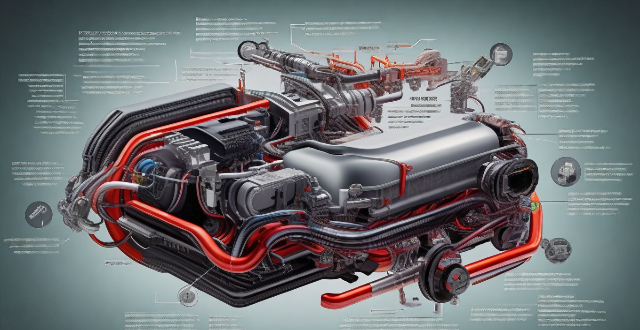

How does an electronic speed controller work ?

An electronic speed controller (ESC) regulates the speed of an electric motor by controlling the electrical power sent to it. It receives a signal, typically a pulse-width modulation (PWM) signal, which it interprets as a desired speed for the motor. The ESC then converts this low-power signal into a high-power electrical current that can drive the motor. By adjusting the duty cycle of the PWM signal, the ESC controls the motor's speed and torque. It also includes features such as overcurrent protection and cooling to ensure reliable operation. Some ESCs even have a feedback loop to monitor the actual speed of the motor and adjust the power output accordingly.

How does a single motor drive work ?

The motor drive converts incoming AC power to DC, controls the motor's speed via PWM, regulates its torque by monitoring current and adjusting voltage, and ensures proper operation through feedback control.

How do I install an electronic speed controller in my vehicle ?

An Electronic Speed Controller (ESC) is a device that regulates the speed of an electric motor. It is commonly used in RC cars, drones, and other electronic devices to maintain consistent speed and improve performance. In the context of vehicles, an ESC can be used to control the speed of electric motors in electric or hybrid cars. Installing an ESC in your vehicle involves several steps, which may vary depending on the specific model and make of your vehicle. Here's a general guide to get you started: 1. Choose the right ESC for your vehicle. 2. Disconnect the battery before working on any electrical system in your vehicle. 3. Remove the old controller (if applicable). 4. Mount the ESC in a suitable location within your vehicle. 5. Connect wires and motor according to the manufacturer's instructions. 6. Reconnect the battery and test the system. There are several reasons why you might want to install an ESC in your vehicle, including improved performance, better control, and additional safety features such as overcurrent protection. When installing an ESC, it's important to follow the manufacturer's instructions, wear protective gear, and seek professional assistance if needed.

What is a brushless motor ?

Brushless motors, also known as BLDC (Brushless Direct Current) motors, are electric motors that use an electronic controller to switch the current in their stator windings. They have higher efficiency, longer lifespan, higher power density, lower maintenance requirements, and quieter operation compared to brushed motors. The working principle of a brushless motor involves three main components: the rotor, stator, and electronic controller. Brushless motors are used in various applications, including aircraft, automotive, appliances, and industrial equipment.

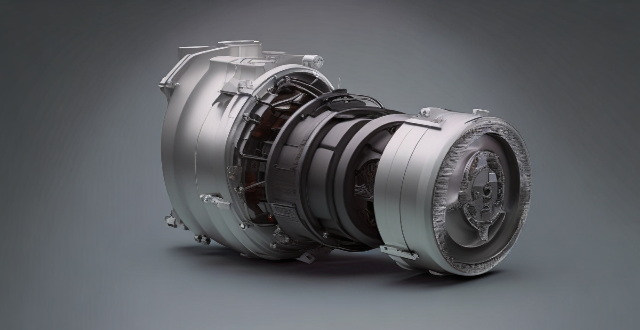

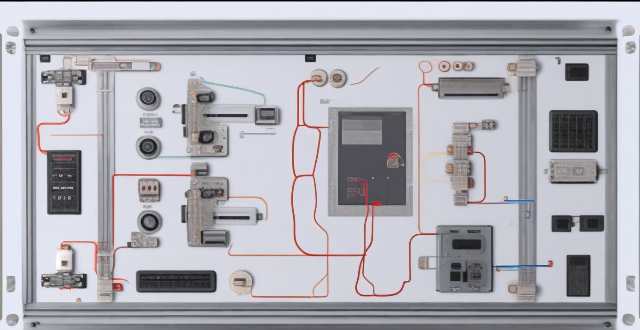

How do I install and maintain a combination motor drive system ?

A combination motor drive system, also known as an integrated drive system or hybrid drivetrain, is a complex assembly of components designed to deliver power from the engine to the wheels of a vehicle. It typically includes an internal combustion engine, one or more electric motors, and a transmission that may incorporate both mechanical and electronic control systems. This guide will walk you through the installation and maintenance process for such a system.

What are the advantages of using a brushless motor ?

Brushless motors offer several advantages over traditional brushed motors, including higher efficiency, longer lifespan, improved performance, quieter operation, enhanced reliability, and environmental benefits. These benefits make them an attractive choice for a wide range of applications.

How do I maintain and care for my brushless motor ?

Taking care of your brushless motor is essential to ensure its longevity and performance. Here are some tips on how to maintain and care for your brushless motor: Regular Cleaning: - Clean the motor, heat sink, and propeller regularly to remove dirt, dust, or debris. Lubrication: - Lubricate the bearings with a high-quality lubricant to reduce friction and wear. - Avoid overlubrication as it can attract dirt and debris. Inspection: - Inspect the motor, wiring connections, and propeller for any signs of damage or corrosion. - Replace damaged components or the entire motor if necessary. Storage: - Store your brushless motor in a dry place to prevent moisture from entering the motor. - Avoid storing the motor in direct sunlight to prevent discoloration and damage to the components. Usage: - Avoid overloading the motor by using the appropriate propeller size and battery voltage. - Use a LiPo battery with an appropriate C rating for optimal performance. - Avoid exposing the motor to water as it can cause damage to the electronic components. By following these maintenance and care tips, you can ensure that your brushless motor performs at its best and lasts for a long time.

How does a multi-motor drive system work ?

The text explains how a multi-motor drive system works, its components, and benefits. It describes the process of power conversion, control signals, motor operation, mechanical transmission, and feedback adjustment in such systems. The advantages include improved efficiency, increased redundancy, and enhanced control.

How can I choose the right combination motor drive for my application ?

When selecting a combination motor drive for your application, consider factors such as the type of motor (AC, DC, stepper, or servo), application requirements (load characteristics, speed and torque needs, control precision), appropriate drive technology (VFDs, electronic speed controls, stepper motor drives, servo amplifiers), compatibility and integration with existing systems, performance features (efficiency, dynamic response, protection features), budget and cost considerations (initial and operating costs), and seek professional advice from manufacturers and technical support.

What are the different types of combination motor drives available in the market ?

The article discusses different types of combination motor drives, including AC, DC, servo, and stepper motor drives. It highlights their unique features such as precise speed control, high torque output, regenerative braking, position control, feedback systems, and microstepping capabilities. The article emphasizes the importance of selecting the appropriate type of motor drive based on the specific needs and requirements of the application.

Can an electronic speed controller be used in a car engine ?

The question of whether an electronic speed controller (ESC) can be used in a car engine depends on the type of engine. In traditional internal combustion engines (ICE), which use gasoline or diesel as fuel, an ESC cannot be used because these engines rely on mechanical systems for speed control. However, in electric cars, which use electric motors as their primary source of propulsion, an ESC is essential for controlling the speed of the motor and protecting it from damage. Therefore, while an ESC cannot be used in ICE vehicles, it plays a crucial role in electric vehicles.

What are the benefits of using an electronic shopping list versus a paper one ?

**Summary:** Electronic shopping lists offer several advantages over paper ones, including convenience, organization, cost savings, environmental friendliness, and time savings. They allow for easy creation, updating, and access; prioritization and categorization of items; avoidance of duplicate purchases; price comparison; coupon management; reduced paper waste; digital receipt storage; less plastic bag use; faster shopping; automatic replenishment; and sharing with family members. As technology advances, electronic shopping lists are likely to become more prevalent and useful in daily life.

How can I find a reliable electronic waste recycling center near me ?

Finding a reliable electronic waste recycling center is crucial for environmental protection, resource conservation, and energy savings. Here's a summary of the steps to find one: 1. Research online using search engines and review websites. 2. Check with local government agencies and solid waste management departments. 3. Ask friends, family, and community groups for recommendations. 4. Look for certifications and accreditations like e-Stewards and R2/RIOS. 5. Visit the recycling center to assess cleanliness and organization. To properly dispose of electronic waste, backup data, remove personal information, and follow manufacturer instructions.

How do electronic devices impact our ability to fall asleep ?

Electronic devices, such as smartphones and laptops, have become an integral part of modern life but their use has raised concerns about their impact on sleep quality and quantity. Exposure to blue light from electronic screens before bedtime can delay the onset of sleep by suppressing the production of melatonin, a hormone responsible for regulating sleep-wake cycles. This means that using electronic devices in the hours leading up to bedtime can make it harder for us to fall asleep. In addition, engaging with stimulating content on electronic devices can lead to mental arousal, making it difficult for us to relax and fall asleep. To reduce the impact of electronic devices on sleep, consider implementing tips such as establishing a relaxing bedtime routine, limiting screen time before bed, creating a technology-free sleep environment, and engaging in mindfulness practices.

What is the difference between single motor and multi-motor drives ?

Single motor drives control only one motor and are simple, cost-effective, and easy to maintain. Multi-motor drives control multiple motors simultaneously and offer increased flexibility, improved performance, and enhanced functionality but are more complex and expensive. The choice between these two types of drives depends on the specific requirements of the application.

What is a hub motor ?

A hub motor is an electric motor integrated into a vehicle's wheel hub, offering direct drive, simplified design, quiet operation, and space efficiency. However, it has limitations such as limited power output, overheating concerns, and cost considerations. Hub motors are commonly used in electric vehicles like bicycles, scooters, motorcycles, and cars.

How does electronic waste affect the environment if not recycled ?

Electronic waste, or e-waste, refers to discarded electronic devices such as computers, smartphones, and televisions. Improper disposal of these items can have severe consequences for the environment, including the release of toxic chemicals into soil, water, and air. These chemicals can cause health problems for both humans and wildlife. Non-recycled e-waste also occupies valuable landfill space and contributes to soil contamination, water pollution, and air pollution. Proper recycling of electronic waste is essential to protect the environment and human health, conserve natural resources, and minimize the impact on landfills.

Can I use homemade cleaners on electronic devices, or will they cause damage ?

Homemade cleaners are cost-effective and environmentally friendly, but using them on electronic devices can be risky. Some homemade cleaners, like vinegar and lemon juice, are acidic and can damage sensitive parts of electronic devices. Others, like baking soda, are abrasive and can scratch surfaces or leave a residue behind. Commercial cleaners, on the other hand, are specifically designed for electronic devices and are tested for safety. Therefore, it is recommended to use commercial cleaners on electronic devices to ensure their safety and longevity.

What impact has electronic health records had on the efficiency of medical practices ?

Electronic health records (EHRs) have revolutionized the healthcare industry by providing a digital platform for storing, managing, and exchanging patient information. This has led to significant improvements in the efficiency of medical practices. In this article, we will discuss the various ways in which EHRs have impacted the efficiency of medical practices. Benefits of Electronic Health Records: - Improved accessibility with faster retrieval and remote access - Enhanced communication through secure messaging and patient portals - Streamlined workflow with automated tasks and reduced paperwork - Improved quality of care with error reduction and clinical decision support - Data analysis and reporting simplified by data mining and regulatory compliance Challenges Faced with Electronic Health Records: - High implementation costs and staff training requirements - Interoperability issues and data exchange challenges - Security concerns related to data breaches and privacy protection In conclusion, electronic health records have had a significant impact on the efficiency of medical practices by improving accessibility, enhancing communication, streamlining workflow, improving quality of care, and simplifying data analysis and reporting. However, challenges such as cost, training, interoperability issues, and security concerns must be addressed to fully realize the potential benefits of EHRs in healthcare settings.

What happens to my data after I recycle my electronic devices ?

When you recycle your electronic devices, several stepsWhen you recycle your electronic devices, several steps data is securely erased several steps are taken to ensure your data is securely erased and the device is properly disposed of. This includes data erasure, disassembly, recycling, reuse and donation, and final disposal. Recycling helps protect your personal data and reduces environmental impact by conserving resources and reducing waste.

Which industries commonly use combination motor drives ?

Combination motor drives, or variable frequency drivesCombination motor drives, or variable frequency drives are electronic devices that control the or variable frequency drives (VFDs), are electronic devices that control the speed of AC electric motors. They are widely used in various industries for energy saving, control precision, and process optimization. Some sectors where combination motor drives are commonly employed include manufacturing and production industries, such as food and beverage processing, pharmaceuticals, automotive manufacturing, paper and pulp, energy and utilities, transportation and logistics, HVAC and refrigeration, textile and garment industry, pumps and compressed air systems. The adaptability and efficiency benefits of combination motor drives make them an integral part of modern industrial processes.

How do you choose the right AC stepping motor for your project ?

Choosing the right AC stepping motor requires understanding project needs, selecting the appropriate motor type, ensuring compatibility with control systems, considering physical constraints, evaluating performance characteristics, accounting for environmental factors, managing budgetary considerations, relying on supplier support and reputation, and conducting thorough testing.

Can you provide some examples of applications where multi-motor drives are used ?

Multi-motor drives are used in various applications where multiple motors need to be controlled simultaneously, including industrial automation, CNC machines, electric vehicles, wind turbines, robotics, and aerospace.

Are brushless motors more efficient than brushed motors ?

Brushless motors are more efficient than brushed motors due to their lack of friction, reduced maintenance requirements, higher RPM range, improved torque control, and better power-to-weight ratio.