Brushless motors, also known as BLDC (Brushless Direct Current) motors, are electric motors that use an electronic controller to switch the current in their stator windings. They have higher efficiency, longer lifespan, higher power density, lower maintenance requirements, and quieter operation compared to brushed motors. The working principle of a brushless motor involves three main components: the rotor, stator, and electronic controller. Brushless motors are used in various applications, including aircraft, automotive, appliances, and industrial equipment.

Introduction

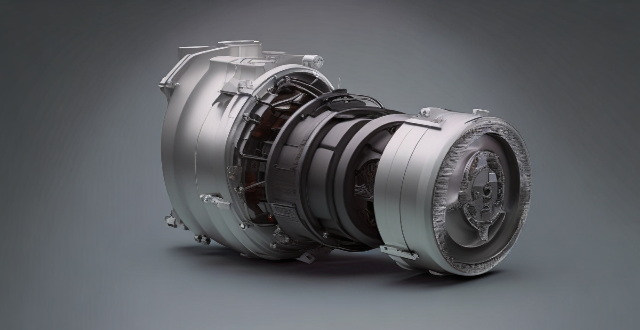

A brushless motor, also known as a BLDC (Brushless Direct Current) motor, is an electric motor that uses an electronic controller to switch the current in its stator windings. Unlike traditional DC motors, which use carbon brushes to commutate the armature winding, brushless motors use a rotating permanent magnet in the rotor and stationary coils in the stator.

Features of Brushless Motors

- High efficiency: Brushless motors have higher efficiency than brushed motors because they do not experience brush friction or electrical losses associated with brushes.

- Long lifespan: Since there are no brushes to wear out, brushless motors can last much longer than brushed motors.

- High power density: Brushless motors can produce more power per unit volume compared to brushed motors.

- Low maintenance: Brushless motors require less maintenance due to the absence of brushes.

- Quiet operation: Brushless motors operate more quietly than brushed motors because there is no sparking at the brushes.

Working Principle of Brushless Motors

The working principle of a brushless motor involves three main components: the rotor, stator, and electronic controller. The rotor contains a permanent magnet, while the stator consists of multiple coils of wire arranged around the rotor. The electronic controller controls the flow of current through each coil in a specific sequence to create a rotating magnetic field that interacts with the permanent magnet in the rotor, causing it to rotate.

Applications of Brushless Motors

Brushless motors are used in various applications, including:

- Aircraft: Brushless motors are commonly used in radio-controlled aircraft due to their high efficiency and low weight.

- Automotive: Brushless motors are used in electric vehicles and hybrid cars as traction motors.

- Appliances: Brushless motors are used in household appliances such as washing machines and dishwashers due to their long lifespan and quiet operation.

- Industrial equipment: Brushless motors are used in industrial equipment such as pumps, fans, and conveyors due to their high efficiency and low maintenance requirements.

Advantages of Using Brushless Motors over Brushed Motors

- Higher efficiency: Brushless motors have higher efficiency than brushed motors because they do not experience brush friction or electrical losses associated with brushes.

- Longer lifespan: Since there are no brushes to wear out, brushless motors can last much longer than brushed motors.

- Higher power density: Brushless motors can produce more power per unit volume compared to brushed motors.

- Lower maintenance: Brushless motors require less maintenance due to the absence of brushes.

- Quieter operation: Brushless motors operate more quietly than brushed motors because there is no sparking at the brushes.