Motor Gasoline

Do gasoline hybrid cars require special maintenance ?

This text discusses the maintenance requirements for gasoline hybrid cars, which combine a conventional engine with an electric motor for added efficiency. While these vehicles do not require extensive special maintenance, there are specific components that need attention. Regular maintenance such as oil changes, tire rotations, brake checks, and air filter replacements are still essential. Additionally, hybrid-specific maintenance includes monitoring battery health, checking the regenerative braking system, ensuring proper cooling of the electric motor, and maintaining transmission fluid levels. It is important to refer to the vehicle's owner's manual for specific maintenance schedules and seek out professional service when needed. By addressing both conventional and hybrid-specific maintenance needs, gasoline hybrid cars can run reliably and efficiently.

Can I still use gasoline in a gasoline hybrid car ?

Gasoline hybrid cars combine a traditional gasoline engine with an electric motor for improved fuel efficiency and reduced emissions. While they still require gasoline to operate the internal combustion engine, they offer significant savings in fuel costs over time. To maximize fuel efficiency in a gasoline hybrid car, drivers should practice eco-driving techniques, perform regular maintenance, and utilize regenerative braking settings. Gasoline hybrid cars represent a step towards reducing our reliance on fossil fuels and transitioning to cleaner energy sources.

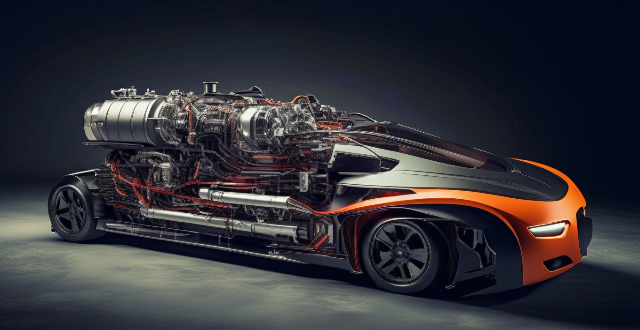

How does a gasoline hybrid car work ?

Gasoline hybrid vehicles, known as HEVs, merge an ICE with an electric motor for enhanced efficiency and reduced emissions. Key components include the ICE, electric motor, battery pack, transmission, and a generator/alternator. These cars can operate in various modes: fully on ICE power, purely electric, combined power, or through regenerative braking. The energy management controller optimizes power distribution for peak efficiency. Benefits of gasoline hybrids include better fuel economy, lower emissions, extended brake life, and potential tax incentives.

What are the benefits of a gasoline hybrid engine ?

The article discusses the advantages of a gasoline hybrid engine, which is a combination of a traditional internal combustion engine and an electric motor. The benefits include improved fuel efficiency through reduced fuel consumption, regenerative braking, and start-stop technology; lower CO2 emissions and decreased pollutants resulting in cleaner air quality; and enhanced performance with instant torque, smooth driving experience, and extended brake life due to regenerative braking. Overall, gasoline hybrid engines provide a balance between power and efficiency, making them an attractive option for eco-conscious drivers.

How much more expensive is a gasoline hybrid car compared to a regular gasoline car ?

The cost difference between a gasoline hybrid car and a regular gasoline car can vary depending on several factors such as brand, model, features, and location. However, in general, gasoline hybrid cars tend to be more expensive than regular gasoline cars. Here are some key points to consider: - Gasoline Hybrid Cars: These vehicles typically have a higher initial cost compared to regular gasoline cars due to the additional technology required for the hybrid system. The price difference can range from a few thousand dollars to over $10,000, depending on the make and model. One of the main advantages of gasoline hybrid cars is their improved fuel efficiency. They use both gasoline and electricity to power the engine, which results in better mileage and lower fuel costs over time. While gasoline hybrid cars may have higher repair costs due to their complex systems, they often require less maintenance overall because the electric motor helps reduce wear and tear on the engine. As awareness of environmental issues grows, so does the demand for eco-friendly vehicles like gasoline hybrid cars. This increased demand can help maintain or even increase their resale value over time. - Regular Gasoline Cars: These vehicles are generally less expensive upfront as they do not require the same advanced technology as hybrid cars. These vehicles rely solely on gasoline for power, which can lead to higher fuel consumption and expenses, especially if you drive long distances or frequently idle in traffic. These vehicles may have lower repair costs initially but may require more frequent maintenance, such as oil changes and tune-ups, due to their reliance on a single power source. The resale value of regular gasoline cars may decline faster than that of hybrid cars, especially as more buyers seek out fuel-efficient options.

Are gasoline hybrid cars better for the environment than traditional gasoline cars ?

Gasoline hybrid cars, also known as hybrid electric vehicles (HEVs), are becoming increasingly popular due to their potential environmental benefits. These vehicles produce fewer emissions compared to traditional gasoline cars and have better fuel efficiency. They also use regenerative braking technology, which captures energy normally lost during braking and stores it in the battery, further improving fuel efficiency and reducing emissions. However, gasoline hybrid cars also have drawbacks such as higher upfront cost, limited electric-only range, and potential environmental impacts from battery production and disposal. Traditional gasoline cars, on the other hand, are generally less expensive than gasoline hybrid cars and have a widespread refueling infrastructure. They are also often simpler and more reliable than gasoline hybrid cars. In conclusion, gasoline hybrid cars offer several environmental benefits over traditional gasoline cars, but they also come with drawbacks. The decision between a gasoline hybrid car and a traditional gasoline car depends on individual preferences, priorities, and circumstances.

What is the difference between a gasoline hybrid and an electric car ?

The main difference between a gasoline hybrid and an electric car is their fuel source and how they generate energy. Gasoline hybrids run on a combination of gasoline and electricity, while electric cars run solely on electricity. Gasoline hybrids produce lower emissions than traditional gasoline-powered vehicles but still require gasoline to operate. Electric cars produce zero tailpipe emissions but may still result in emissions from electricity production. Finally, gasoline hybrids typically have a longer range than electric cars due to their ability to switch between using gasoline and electricity depending on driving conditions.

How far can a gasoline hybrid car travel on a full tank of gas ?

The text discusses the fuel efficiency and range of gasoline hybrid cars on a full tank of gas. Factors affecting fuel efficiency include driving habits, traffic conditions, vehicle maintenance, and weather conditions. Gasoline hybrid cars typically have higher fuel efficiency ratings than traditional gasoline-powered cars due to their combination of an electric motor and a gasoline engine. The estimated range of many gasoline hybrid cars is around 300-500 miles on a full tank of gas, with some having larger fuel tanks or higher fuel efficiency ratings allowing for greater ranges. Maximizing fuel efficiency can be achieved by considering factors such as driving habits and vehicle maintenance.

Are electric cars more expensive than gasoline cars ?

Electric cars, also known as EVs, have been gaining popularity due to their eco-friendly nature and lower operating costs. However, the initial purchase price of an electric car is often higher than that of a traditional gasoline-powered car. In this article, we will explore the cost differences between electric and gasoline cars. ## Upfront Cost **Electric Cars:** - Higher upfront cost due to expensive battery technology and limited production scale. - Prices vary depending on the model, brand, and range. - Some governments offer incentives and tax credits to offset the high initial cost. **Gasoline Cars:** - Generally less expensive upfront compared to electric cars. - Wide variety of models and brands available at different price points. - No government incentives or tax credits for purchasing a gasoline car. ## Operating Costs **Electric Cars:** - Lower operating costs due to cheaper electricity rates compared to gasoline prices. - Maintenance costs are generally lower since there are fewer moving parts in an electric motor. - Battery replacement can be costly, but it is not expected until after several years of use. **Gasoline Cars:** - Higher operating costs due to fluctuating gasoline prices and regular maintenance requirements. - More frequent oil changes, tune-ups, and other routine maintenance tasks. - Fuel efficiency varies widely among gasoline cars, affecting overall operating costs. ## Depreciation **Electric Cars:** - Depreciation rate may be higher for electric cars due to rapid advancements in technology and changing consumer preferences. - Some early adopters may experience significant depreciation if they choose to sell their electric car before its battery lifespan ends. **Gasoline Cars:** - Generally slower depreciation rate compared to electric cars. - Well-maintained gasoline cars can retain their value for longer periods. ## Resale Value **Electric Cars:** - Resale value depends on factors such as battery health, range, and charging infrastructure availability. - As more people switch to electric cars, the demand for used electric vehicles may increase, potentially boosting resale values. **Gasoline Cars:** - Resale value is typically more predictable and stable compared to electric cars. - Factors such as fuel efficiency, brand reputation, and vehicle condition affect resale value. In conclusion, while electric cars may have a higher upfront cost, they offer lower operating costs and potentially better resale value in the future. It's essential for consumers to consider both short-term and long-term costs when deciding between an electric or gasoline car.

Do hybrid cars produce less pollution than traditional gasoline cars ?

Hybrid cars generally produce less pollution than traditional gasoline cars, but the comparison is not straightforward and various factors must be taken into account.

How do parallel hybrid electric vehicles (PHEVs) compare to traditional gasoline cars in terms of performance ?

Parallel Hybrid Electric Vehicles (PHEVs) offer better acceleration and fuel efficiency than traditional gasoline cars but may have lower top speeds and require more time for recharging. Gasoline cars have higher top speed capabilities and quicker refueling but are less efficient and require more maintenance. The choice between the two depends on individual needs and preferences.

How do electric cars compare to hybrid cars ?

Electric cars run solely on electricity and produce zero emissions, while hybrid cars combine a gasoline engine with an electric motor for improved fuel efficiency. Electric cars offer environmental benefits and lower operating costs but have limited range and long charging times. Hybrids provide a balance between gasoline-powered vehicles and electric cars, with improved fuel efficiency and no range limitations but still rely on gasoline and produce emissions. The choice between the two often depends on individual needs and preferences.

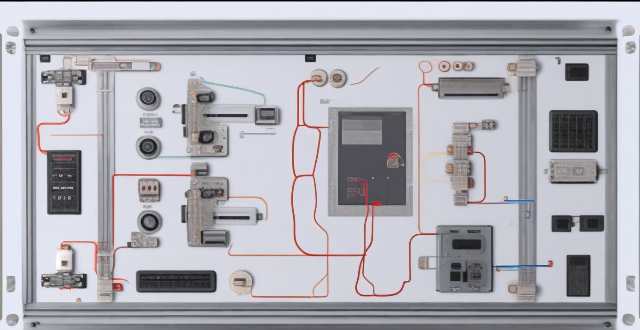

How does a single motor drive work ?

The motor drive converts incoming AC power to DC, controls the motor's speed via PWM, regulates its torque by monitoring current and adjusting voltage, and ensures proper operation through feedback control.

How do power batteries compare to traditional gasoline engines in terms of cost and efficiency ?

Power batteries and traditional gasoline engines are two different types of energy sources that are used to power vehicles. In this article, we will compare the cost and efficiency of power batteries and traditional gasoline engines. Power batteries have a higher initial cost than traditional gasoline engines, but require less maintenance and have lower fuel costs. They also have a higher energy conversion efficiency and can recharge through regenerative braking. However, they have a limited range compared to traditional gasoline engines. Traditional gasoline engines have a lower initial cost than power batteries, but require more maintenance and have higher fuel costs. They also have a lower energy conversion efficiency and cannot recharge through regenerative braking. However, they have a longer range than power batteries. Overall, while power batteries have a higher initial cost and limited range compared to traditional gasoline engines, they offer several advantages in terms of cost and efficiency. As technology continues to advance, it is likely that power batteries will become even more cost-effective and efficient compared to traditional gasoline engines.

What is the difference between single motor and multi-motor drives ?

Single motor drives control only one motor and are simple, cost-effective, and easy to maintain. Multi-motor drives control multiple motors simultaneously and offer increased flexibility, improved performance, and enhanced functionality but are more complex and expensive. The choice between these two types of drives depends on the specific requirements of the application.

What is a hub motor ?

A hub motor is an electric motor integrated into a vehicle's wheel hub, offering direct drive, simplified design, quiet operation, and space efficiency. However, it has limitations such as limited power output, overheating concerns, and cost considerations. Hub motors are commonly used in electric vehicles like bicycles, scooters, motorcycles, and cars.

How do you choose the right AC stepping motor for your project ?

Choosing the right AC stepping motor requires understanding project needs, selecting the appropriate motor type, ensuring compatibility with control systems, considering physical constraints, evaluating performance characteristics, accounting for environmental factors, managing budgetary considerations, relying on supplier support and reputation, and conducting thorough testing.

Can you provide some examples of applications where multi-motor drives are used ?

Multi-motor drives are used in various applications where multiple motors need to be controlled simultaneously, including industrial automation, CNC machines, electric vehicles, wind turbines, robotics, and aerospace.

How do gasoline hybrid cars perform in cold weather ?

Gasoline hybrid cars' performance in cold weather can be affected by reduced battery capacity, thicker engine oil, and decreased tire traction. Proper maintenance and adjustments to driving habits are crucial for safe and efficient operation during the colder months.

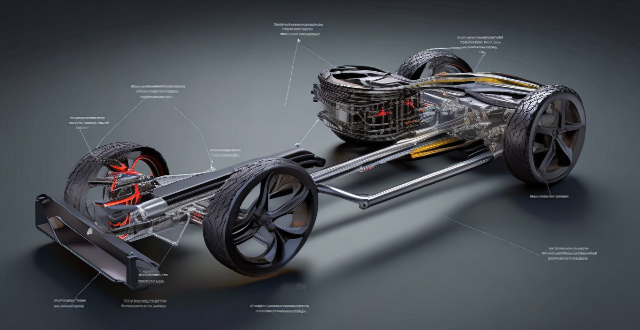

How does a parallel hybrid electric vehicle (PHEV) work ?

Parallel hybrid electric vehicles (PHEVs) are a type of hybrid vehicle that combines an internal combustion engine (ICE) with an electric motor. The two power sources can work independently or together, depending on the driving conditions. PHEVs have three operating modes: ICE only, electric motor only, and combined power. The energy management system controls the operation of the ICE and electric motor, deciding which power source to use based on driving conditions, battery state of charge, and other factors. PHEVs offer benefits such as improved fuel efficiency, reduced emissions, tax incentives, and reduced dependence on fossil fuels.

Can a combination motor drive improve energy efficiency in my facility ?

Combination motor drives can improve energy efficiency in facilities by optimizing electric motor performance, reducing energy consumption, and extending equipment lifespan. They offer variable speed control, soft start/stop capabilities, and reactive power compensation features that contribute to lower energy bills, reduced maintenance costs, and environmental benefits like reduced greenhouse gas emissions.

How does a single motor drive compare to a dual motor drive ?

This article compares single motor drives and dual motor drives based on their performance, efficiency, cost, and applications. Single motor drives can only control one motor at a time, while dual motor drives can control two motors simultaneously. Dual motor drives offer higher overall torque and better synchronization between multiple motors, but they also consume more power and require more maintenance. Single motor drives are typically less expensive and well-suited for low power applications with simple movement profiles, while dual motor drives are appropriate for high power applications with complex movement profiles requiring precise synchronization. The choice between a single motor drive and a dual motor drive depends on the specific requirements of the application.

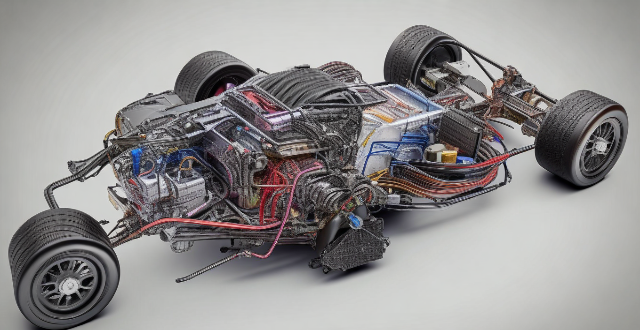

How does a multi-motor drive system work ?

The text explains how a multi-motor drive system works, its components, and benefits. It describes the process of power conversion, control signals, motor operation, mechanical transmission, and feedback adjustment in such systems. The advantages include improved efficiency, increased redundancy, and enhanced control.

What are the advantages and disadvantages of using a combination motor drive compared to a single motor drive ?

The combination motor drive has several advantages over a single motor drive, including improved performance, enhanced reliability, flexibility in design, energy efficiency, and modularity and scalability. However, it also has disadvantages such as complexity, cost, space requirements, synchronization issues, and integration challenges.

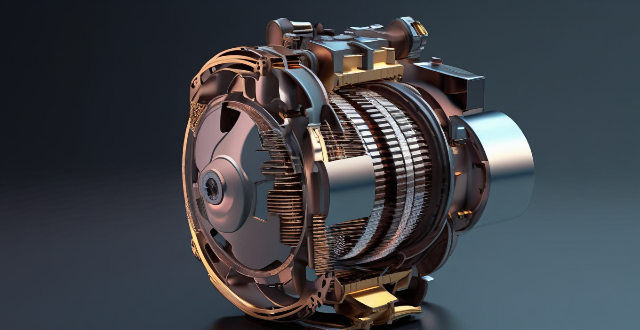

What is an internal rotor motor ?

The text discusses the design, advantages, disadvantages, and applications of internal rotor motors. Internal rotor motors are a type of electric motor where the moving part (rotor) is inside the stationary part (stator). They offer benefits such as high efficiency, good heat dissipation, simplicity in construction, and low inertia. However, they also have limitations like limited torque density, difficulty in cooling, and potential for magnetic saturation. These motors are commonly used in automotive, aerospace, industrial equipment, and consumer electronics applications.

How does the design of a permanent magnet motor differ from an induction motor ?

The article discusses the differences between permanent magnet motor and induction motor design, focusing on three main aspects: rotor design, stator winding design, and cooling system. The rotor of a permanent magnet motor contains high-energy rare-earth magnets that interact with the stator windings to produce torque, while the rotor of an induction motor has aluminum or copper bars that induce currents when exposed to a rotating magnetic field produced by the stator windings. The stator winding design also varies between the two types of motors, with permanent magnet motors typically having a three-phase distributed winding and induction motors having either a distributed or concentrated winding. Finally, the cooling system design differs as well, with permanent magnet motors often relying on natural convection or forced air cooling, while induction motors may use external fans or blowers for more effective heat removal. Understanding these differences is crucial for engineers to choose the appropriate motor type for their needs and optimize its performance accordingly.

How do you maintain and troubleshoot a DC brushed motor ?

Maintaining and Troubleshooting a DC Brushed Motor involves regular cleaning, lubrication, brush replacement, heat management, and monitoring voltage and current. Troubleshooting steps include checking for no power, reduced performance, excessive heat, vibration or noise, sparking, intermittent operation, and smoke or burning smell. Proper maintenance and troubleshooting can prolong the lifespan and ensure reliable operation of the motor.

How does a multi-motor drive system contribute to energy savings in industrial processes ?

A multi-motor drive system contributes to energy savings in industrial processes by optimizing the operation of multiple motors. It balances loads, controls speed optimally, provides reactive power compensation, enables regenerative braking, and reduces maintenance costs. This technology helps businesses improve their bottom line while reducing their environmental footprint.

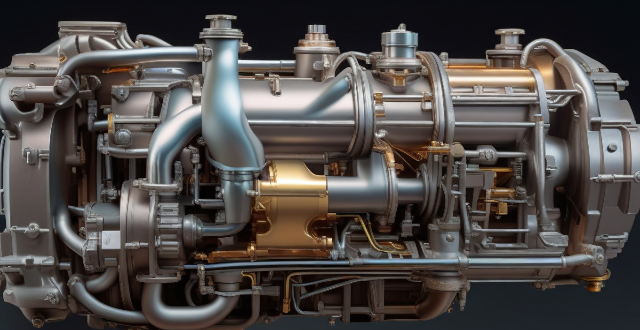

How does a hybrid car work ?

A hybrid car uses a combination of an internal combustion engine and electric motors to achieve better fuel economy and reduced emissions. It consists of key components like the ICE, electric motor(s), battery pack, transmission, control unit, and a charging system that includes regenerative braking. The car operates in various modes: starting with the electric motor, driving with either or both power sources, using regenerative braking for efficiency and battery charging, minimizing idling by shutting down the ICE at stops, and managing the battery's state of charge and health. Benefits include improved gas mileage, lower emissions, enhanced performance, and reduced wear and tear on vehicle components.

What are the benefits of using a combination motor drive system ?

Combination motor drive systems offer benefits such as improved efficiency, increased reliability, flexibility, and enhanced control. These systems combine the advantages of different types of motors to create a more efficient and reliable drive system. They are ideal for a wide range of applications and can help businesses save money on energy costs while reducing downtime and maintenance requirements.