Safety Controller

What safety precautions should be taken while working with a speed controller ?

Working with a speed controller can be dangerous if proper safety precautions are not taken. Here are some important safety measures to consider: ## General Safety Tips - Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hearing protection when working with a speed controller. - Ensure that the work area is well-lit and free from any tripping or slipping hazards. - Keep all tools and materials organized and stored safely to prevent accidents. - Be aware of your surroundings and any potential hazards that may exist in the work environment. ## Electrical Safety - Disconnect power to the speed controller before performing any maintenance or repairs. - Use insulated tools when working on electrical components. - Avoid touching exposed wires or terminals with bare hands. - Do not work on a speed controller if you are standing on a damp or wet surface. ## Mechanical Safety - Use appropriate lockout/tagout procedures to prevent accidental startup of machinery during maintenance or repair. - Ensure that guards and shields are in place and functioning properly. - Be cautious around moving parts and avoid reaching across or under moving machinery. - Use caution when handling heavy objects to avoid straining muscles or causing injury. ## Chemical Safety - If chemicals are used in conjunction with the speed controller, ensure proper ventilation is provided. - Store chemicals in their original containers and keep them away from heat sources or open flames. - Follow all manufacturer instructions for handling and disposal of chemicals.

Can a speed controller be used to control the speed of an electric motor ?

A speed controller is a device that adjusts the electrical power supplied to an electric motor to change its speed. There are several types of speed controllers available for electric motors, including variable frequency drives (VFDs), DC motor controllers, and phase controllers. Using a speed controller has benefits such as energy efficiency, improved performance, extended motor lifespan, and enhanced safety.

Are there any safety precautions I should take when working with an electronic speed controller ?

Working with electronic speed controllers (ESCs) requires careful attention to safety precautions to prevent injuries or damage to equipment. Some important safety measures include disconnecting power sources, wearing protective gear, using proper tools, following manufacturer's instructions, keeping away from flammable materials, being cautious with high voltage, avoiding overloading, and seeking professional help if unsure about proper installation or operation.

How does a PID (Proportional Integral Derivative) controller differ from other types of speed controllers ?

A PID controller uses three control mechanisms to adjust output based on input error, differing from other speed controllers in flexibility and adaptability.

How do I troubleshoot a speed controller if it's not functioning properly ?

Troubleshooting a Speed Controller: If your speed controller is not functioning properly, there are several steps you can take to troubleshoot the issue. Here are some tips: 1. Check the power source. 2. Inspect the wiring and connections. 3. Examine the motor and load. 4. Test the control signals. 5. Check the settings and parameters. 6. Test other components.

What factors should I consider when choosing an electronic speed controller for my application ?

Choosing the right electronic speed controller for your application requires considering several factors, including power requirements, compatibility with your system, accuracy and precision, ease of use and programming, reliability and durability, and cost-effectiveness. Ensure that the chosen controller can handle the maximum power output required by your system, is compatible with all components, offers accurate and precise control, is easy to program and operate, is reliable and durable enough to withstand harsh operating conditions, and offers good value for money.

What is a speed controller and how does it work ?

Speed controllers regulate the speed of electric motors and are used in various applications requiring precise speed control, such as industrial machinery. They consist of an input stage for power supply, a control stage using PID controllers to adjust voltage based on motor speed feedback, and an output stage that converts adjusted voltage for motor use.

How do I choose the right speed controller for my application ?

Choosing the right speed controller for your application involves considering factors such as the type of control needed, power requirements, performance specifications, compatibility with other system components, and cost-effectiveness. Open-loop systems are simpler and less expensive but less accurate, while closed-loop systems offer higher accuracy at a higher cost and complexity. Power considerations include load inertia, duty cycle, and peak power. Performance factors include accuracy, response time, and stability. Compatibility issues involve motor type, control signals, and mounting options. Lastly, weigh the initial cost against long-term reliability and maintenance expenses to ensure you select a speed controller that meets your needs and budget.

Is it possible to upgrade my existing mechanical speed controller to an electronic one ?

Mechanical speed controllers have been used for a long time in various applications, such as fans, pumps, and other machinery. However, with the advancement of technology, electronic speed controllers have become more popular due to their advantages over mechanical ones. In this article, we will discuss whether it is possible to upgrade your existing mechanical speed controller to an electronic one. The first factor to consider is compatibility. You need to ensure that the electronic speed controller is compatible with your existing motor and system. This may require consulting with a professional or the manufacturer of both the motor and the electronic speed controller. Another important factor is power requirements. You need to make sure that the electronic speed controller can handle the power output of your motor. If not, you may need to upgrade your motor as well. Installation is another crucial aspect to consider when upgrading from a mechanical to an electronic speed controller. This may require additional wiring and configuration changes, which should be done by a professional to ensure proper installation and operation. Finally, you need to consider the cost of upgrading. While electronic speed controllers offer many advantages, they can be more expensive than mechanical ones. You should weigh the initial cost against the potential long-term savings in energy consumption and maintenance costs before making a decision. In conclusion, it is possible to upgrade your existing mechanical speed controller to an electronic one, but several factors need to be considered before doing so. These include compatibility, power requirements, installation, and cost. By carefully evaluating these factors and consulting with professionals, you can determine if upgrading is the right choice for your application.

Is it possible to build a DIY speed controller, and how would I go about doing so ?

The article discusses the process of building a DIY speed controller using components such as a microcontroller, motor driver, power supply, and motor. It outlines the steps required to connect the components together and provides example code for programming the microcontroller to control the speed of the motor based on the input from a potentiometer. The article also mentions that testing and troubleshooting may be necessary to ensure proper operation of the speed controller.

What are the benefits of using an electronic speed controller ?

Benefits of Using an Electronic Speed Controller An electronic speed controller (ESC) regulates the speed of electric motors by controlling the amount of electrical power delivered to them. It is a crucial component in many electronic devices, particularly in the field of robotics and drones. The benefits of using an ESC include precision control over the motor's speed, increased efficiency by reducing energy consumption, improved safety by preventing damage to components, enhanced performance by allowing for more precise control over the motor's speed, and reduced maintenance costs. These benefits make ESCs essential components in many electronic devices and systems.

How do I install an electronic speed controller in my vehicle ?

An Electronic Speed Controller (ESC) is a device that regulates the speed of an electric motor. It is commonly used in RC cars, drones, and other electronic devices to maintain consistent speed and improve performance. In the context of vehicles, an ESC can be used to control the speed of electric motors in electric or hybrid cars. Installing an ESC in your vehicle involves several steps, which may vary depending on the specific model and make of your vehicle. Here's a general guide to get you started: 1. Choose the right ESC for your vehicle. 2. Disconnect the battery before working on any electrical system in your vehicle. 3. Remove the old controller (if applicable). 4. Mount the ESC in a suitable location within your vehicle. 5. Connect wires and motor according to the manufacturer's instructions. 6. Reconnect the battery and test the system. There are several reasons why you might want to install an ESC in your vehicle, including improved performance, better control, and additional safety features such as overcurrent protection. When installing an ESC, it's important to follow the manufacturer's instructions, wear protective gear, and seek professional assistance if needed.

Can an electronic speed controller be used in a car engine ?

The question of whether an electronic speed controller (ESC) can be used in a car engine depends on the type of engine. In traditional internal combustion engines (ICE), which use gasoline or diesel as fuel, an ESC cannot be used because these engines rely on mechanical systems for speed control. However, in electric cars, which use electric motors as their primary source of propulsion, an ESC is essential for controlling the speed of the motor and protecting it from damage. Therefore, while an ESC cannot be used in ICE vehicles, it plays a crucial role in electric vehicles.

How much does an electronic speed controller cost ?

The cost of an electronic speed controller (ESC) varies depending on brand, type, and features. Popular brands include Hobbywing, Tattu, and SimonK, with prices ranging from $5 to over $100. Brushed ESCs are generally less expensive than brushless ESCs, while more features like higher current ratings and advanced programming options can increase the price. It's important to consider your specific needs and budget when choosing an ESC.

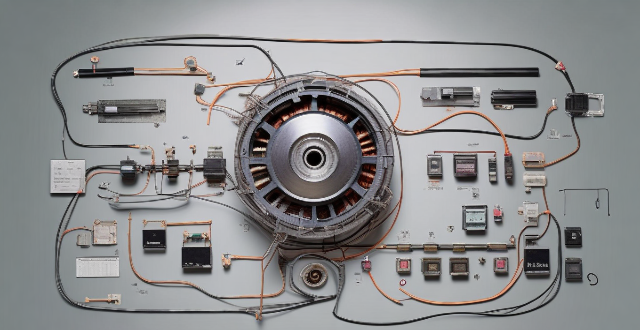

How does a combination motor drive work ?

Combination motor drives integrate VFD and servo controller functionalities to achieve precise speed and torque control for AC induction and permanent magnet synchronous motors. They enhance performance, reduce energy consumption, and extend motor lifespan by offering smooth speed control and reducing wear and tear. Key components include a VFD, servo controller, electric motor, encoder, and user interface. The system uses feedback from an encoder to adjust the motor's input signals, ensuring accurate motion profiles.

What is an electronic speed controller ?

The text provides an overview of electronic speed controllers (ESCs), which are devices used to regulate the power sent to motors in model aircraft and drones. It describes key features such as adjustable throttle, battery protection, signal modulation, and failsafe functionality. The process by which ESCs work is outlined: receiving a signal from the radio transmitter, decoding it into a throttle setting, controlling motor speed based on this setting, and providing feedback to the pilot. Two types of ESCs are mentioned: brushed and brushless, with the latter being more complex and expensive. The text concludes that ESCs are crucial for precise control over motor speed and aircraft performance.

How does an electronic speed controller work ?

An electronic speed controller (ESC) regulates the speed of an electric motor by controlling the electrical power sent to it. It receives a signal, typically a pulse-width modulation (PWM) signal, which it interprets as a desired speed for the motor. The ESC then converts this low-power signal into a high-power electrical current that can drive the motor. By adjusting the duty cycle of the PWM signal, the ESC controls the motor's speed and torque. It also includes features such as overcurrent protection and cooling to ensure reliable operation. Some ESCs even have a feedback loop to monitor the actual speed of the motor and adjust the power output accordingly.

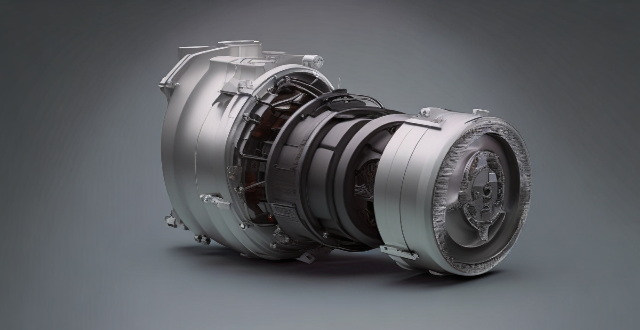

How does a brushless motor work ?

Brushless motors, also known as BLDC motors, are electric motors that use an electronic controller to switch the current in their stator windings. They consist of three main components: the rotor, stator, and electronic controller. The working principle of a brushless motor involves initial rotation, commutation, and maintaining rotation. Brushless motors offer several advantages over traditional brushed motors, including higher efficiency, longer lifespan, better performance, and lower maintenance.

How do safety regulations affect the manufacturing industry ?

Safety regulations are critical in manufacturing for worker safety, environmental protection, and product quality assurance but can increase costs and administrative burden while potentially slowing innovation.

What is a brushless motor ?

Brushless motors, also known as BLDC (Brushless Direct Current) motors, are electric motors that use an electronic controller to switch the current in their stator windings. They have higher efficiency, longer lifespan, higher power density, lower maintenance requirements, and quieter operation compared to brushed motors. The working principle of a brushless motor involves three main components: the rotor, stator, and electronic controller. Brushless motors are used in various applications, including aircraft, automotive, appliances, and industrial equipment.

Are there any disadvantages to using an electronic speed controller ?

Electronic speed controllers (ESCs) have some drawbacks, including complexity, cost, battery drain, and compatibility issues.

How can parents effectively teach their children about safety ?

Teaching children about safety is crucial for their well-being. Parents can effectively teach their children about safety by establishing clear rules, educating them about potential dangers, practicing safety drills, encouraging open communication, and modeling safe behavior. By doing so, children will develop awareness and the ability to protect themselves from potential dangers.

What safety measures are in place on cruise ships ?

Cruise ships implement various safety measures to ensure the well-being of passengers and crew, including muster drills, life-saving equipment, fire safety systems, medical facilities, security personnel, emergency response plans, navigation systems, and regular maintenance checks.

How can technology be used to enhance child safety education ?

Technology can significantly enhance child safety education through various strategies such as interactive learning applications, virtual reality experiences, online safety courses, wearable devices, and social media engagement. These tools not only make learning fun and engaging but also provide practical, real-world simulations that help children develop essential safety skills. By utilizing these modern methods, we can equip the younger generation with the knowledge and confidence needed to stay safe in a rapidly changing world.

What is the importance of using standardized safety symbols and colors on safety signs ?

Using standardized safety symbols and colors on safety signs is crucial for promoting a safe working environment. These signs convey clear, concise information to employees, visitors, and emergency responders about potential hazards and necessary precautions. The importance of these symbols and colors in enhancing safety awareness and reducing accidents will be discussed in this response.

What are the most common workplace safety hazards ?

The most common workplace safety hazards include slips, trips, and falls, fires and explosions, electrical hazards, chemical exposure, repetitive strain injuries (RSIs), noise-induced hearing loss (NIHL), violence and harassment, and ergonomic hazards. Employers should conduct regular risk assessments and provide appropriate training and personal protective equipment (PPE) to mitigate these hazards. Employees should report any potential hazards to their supervisors and participate in safety meetings and training sessions.

What are the legal requirements for workplace safety ?

Legal requirements for workplace safety include compliance with occupational health and safety laws, implementation of a health and safety management system, provision of personal protective equipment (PPE), reporting of injuries and illnesses, and employee participation in health and safety decisions. These measures ensure the well-being of employees and protect the company from potential legal liabilities.

How do safety drills help identify potential hazards in the workplace ?

Safety drills are crucial exercises to simulate and identify potential hazards in the workplace. They help highlight weak links in safety procedures, test equipment and infrastructure, enhance visibility of hazardous areas, train for unexpected circumstances, and promote a culture of safety. By conducting regular drills, organizations can reduce accidents and ensure a safer environment for employees.