Power Drive

How has the development of power electronics influenced the design of modern drive motors ?

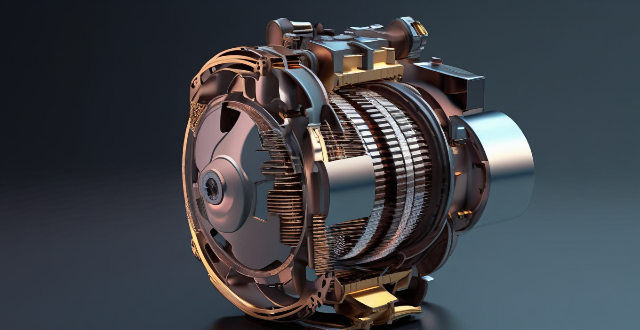

The advancement of power electronics has significantly influenced the design and performance of contemporary drive motors. This technological progress has led to more efficient, reliable, and sophisticated motor control systems, offering a wide array of benefits across various sectors. Here are some key points: - **Enhanced Efficiency and Performance**: Power electronics have enabled advanced control techniques like FOC and DTC, optimizing motor operation for better dynamic response and efficiency. The introduction of VFDs allows motors to operate at varying speeds without mechanical gearboxes or belt drives, enhancing energy efficiency and reducing mechanical wear. - **Improved Reliability and Durability**: Integrated power electronics can monitor motor conditions in real-time, enabling predictive maintenance that reduces downtime and repair costs. Modern drive motors often include protection features like overcurrent, overvoltage, and temperature monitoring, thanks to the integration of power electronics. These safeguards extend the motor's lifespan and ensure stable operation. - **Customizable and Smarter Motors**: Power electronics enable motors with programmable settings that can be tailored to specific applications, improving performance and adaptability. The inclusion of power electronics paves the way for IoT integration, where motors can communicate with other devices, enabling smart grid functionalities and remote diagnostics. - **Environmental Benefits**: By allowing motors to operate at optimal speeds and loads, power electronics contribute to significant energy savings, aligning with global efforts to reduce energy consumption and greenhouse gas emissions. Modern drive motors utilizing power electronics often operate more smoothly, resulting in reduced noise pollution compared to traditional motor designs. - **Scalability and Cost-Effectiveness**: Power electronic components can be designed modularly, making it easier to scale motor designs up or down to meet specific power requirements without starting from scratch. As power electronic components become more standardized and mass-produced, their cost decreases, making advanced motor designs more accessible to a broader range of industries and applications.

How does a single motor drive compare to a dual motor drive ?

This article compares single motor drives and dual motor drives based on their performance, efficiency, cost, and applications. Single motor drives can only control one motor at a time, while dual motor drives can control two motors simultaneously. Dual motor drives offer higher overall torque and better synchronization between multiple motors, but they also consume more power and require more maintenance. Single motor drives are typically less expensive and well-suited for low power applications with simple movement profiles, while dual motor drives are appropriate for high power applications with complex movement profiles requiring precise synchronization. The choice between a single motor drive and a dual motor drive depends on the specific requirements of the application.

What are the advantages and disadvantages of using a combination motor drive compared to a single motor drive ?

The combination motor drive has several advantages over a single motor drive, including improved performance, enhanced reliability, flexibility in design, energy efficiency, and modularity and scalability. However, it also has disadvantages such as complexity, cost, space requirements, synchronization issues, and integration challenges.

How do I install and maintain a combination motor drive system ?

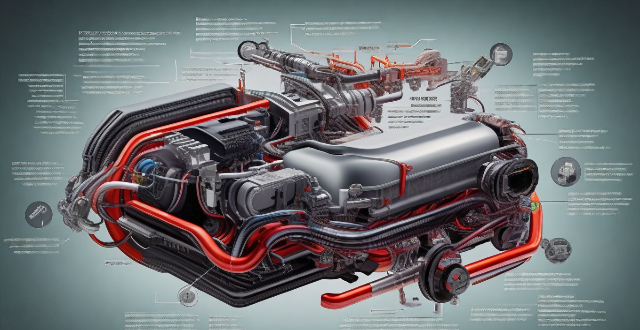

A combination motor drive system, also known as an integrated drive system or hybrid drivetrain, is a complex assembly of components designed to deliver power from the engine to the wheels of a vehicle. It typically includes an internal combustion engine, one or more electric motors, and a transmission that may incorporate both mechanical and electronic control systems. This guide will walk you through the installation and maintenance process for such a system.

What are the advantages of using a single motor drive system ?

A single motor drive system is a type of electric motor control system that uses only one motor to power a machine or equipment. This system has several advantages over other types of drive systems, including simplified design and maintenance, improved efficiency and performance, increased reliability and longevity, and greater flexibility and versatility. These benefits make it an attractive option for many industrial applications where precise control and efficient operation are essential.

How do I choose the right drive motor for my application ?

When selecting a drive motor for your application, considerWhen selecting a drive motor for your application, considerrque and speed, power duty cycle, cost, size, control compatibility, safety compliance, maintenance, and manufacturer reputation. This comprehensive guide helps ensure you choose a motor that meets your needs effectively and efficiently.

How do hub motors compare to mid-drive motors ?

Electric bicycle motors come in two primary configurations: hub motors and mid-drive motors, each with unique characteristics, advantages, and disadvantages suitable for different riding styles and preferences. Hub motors are integrated directly into the bicycle wheel hub, while mid-drive motors are mounted in the center of the bicycle, near the bottom bracket. Hub motors are generally simpler to install and maintain, quieter, and less expensive than mid-drive motors but are less efficient at higher speeds and can affect bike handling due to changes in wheel diameter and weight distribution. Mid-drive motors offer more efficient power delivery at higher speeds, better weight distribution, and adaptability to various wheel sizes but are generally more complex to install and maintain, louder during operation, and more expensive. Choosing between a hub motor and a mid-drive motor depends on what you value most in an e-bike, such as simplicity, quiet operation, lower cost, efficiency at higher speeds, better weight distribution, or adaptability.

What are the challenges faced when designing a multi-motor drive system ?

The article discusses the challenges of designing a multi-motor drive system, including coordination between motors, power distribution, and synchronization. It emphasizes the importance of control algorithms, communication systems, mechanical design, efficiency optimization, power management, thermal management, timing control, feedback mechanisms, and mechanical design in achieving proper operation of the system. The article concludes that careful consideration of these factors is crucial for creating efficient and effective multi-motor drive systems.

Is it possible to upgrade a machine to a single motor drive ?

The text discusses the possibility of upgrading a machine to a single motor drive. It outlines key considerations such as compatibility, performance requirements, and cost considerations. It also provides steps for upgrading to a single motor drive, including evaluating the machine, selecting a suitable motor drive, modifying the machine, installing the motor drive, and testing and optimizing the machine.

How can I choose the right combination motor drive for my application ?

When selecting a combination motor drive for your application, consider factors such as the type of motor (AC, DC, stepper, or servo), application requirements (load characteristics, speed and torque needs, control precision), appropriate drive technology (VFDs, electronic speed controls, stepper motor drives, servo amplifiers), compatibility and integration with existing systems, performance features (efficiency, dynamic response, protection features), budget and cost considerations (initial and operating costs), and seek professional advice from manufacturers and technical support.

What are the key factors to consider when designing a combination motor drive system ?

Designing a combination motor drive system requires careful consideration of several key factors, including load requirements, efficiency and performance, control strategies, reliability and safety, and environmental considerations. Load requirements play a significant role in determining the type and size of the motor required for the drive system, while efficiency and performance are critical factors to consider when designing a motor drive system. Control strategies used in the motor drive system are also crucial, with common strategies including open-loop control, closed-loop control, and adaptive control. Reliability and safety are essential factors to consider when designing a motor drive system, with redundancy, fault detection and protection, and safety interlocks being key considerations. Finally, environmental considerations should also be taken into account when designing a motor drive system, with temperature, humidity, vibration, and shock loads being important factors to consider.

What are the advantages of using a drive motor in industrial equipment ?

Drive motors are crucial components in industrial equipment, offering advantages such as increased efficiency, improved accuracy and precision, flexibility and customization, reduced maintenance and downtime, enhanced safety, and environmental benefits. By optimizing processes for maximum productivity and energy savings, drive motors lead to reduced operating costs and increased profitability for businesses. They also provide precise control over machinery movements, allowing for accurate positioning and repeatable operations, which is particularly important in applications where precision is critical. Drive motors offer flexibility in adjusting the speed, direction, and torque of machinery, accommodating changes and meeting specific requirements. Modern drive motors are designed with reliability and durability, minimizing downtime and increasing productivity. They can also be equipped with safety features to prevent accidents and injuries. Finally, drive motors have positive environmental impacts by improving efficiency and reducing energy consumption, leading to reduced greenhouse gas emissions and less waste material produced during manufacturing processes.

What are the key components of a CHEV's drive system ?

The key components of a CHEV's drive system include the engine, electric motor, transmission, battery pack, and energy management system. The engine generates the majority of the power needed to propel the vehicle, while the electric motor provides additional power during acceleration or hill climbing. The transmission transfers power from the engine and electric motor to the wheels, and may be a conventional automatic or manual transmission or a specialized hybrid transmission. The battery pack stores electrical energy generated by the electric motor during regenerative braking and provides power to the electric motor when needed. The energy management system controls the flow of energy between the engine, electric motor, and battery pack, determining when to use each source of power based on driving conditions, state of charge of the battery, and driver demand. These components work together to provide a seamless driving experience while maximizing fuel efficiency and reducing emissions.

What are the benefits of using a combination motor drive system ?

Combination motor drive systems offer benefits such as improved efficiency, increased reliability, flexibility, and enhanced control. These systems combine the advantages of different types of motors to create a more efficient and reliable drive system. They are ideal for a wide range of applications and can help businesses save money on energy costs while reducing downtime and maintenance requirements.

How can I maximize the lifespan of my electric vehicle's power battery ?

Maximizing the Lifespan of Your Electric Vehicle's Power Battery: Electric vehicles (EVs) are becoming increasingly popular due to their eco-friendliness and cost-effectiveness in the long run. However, one of the most crucial components of an EV is its power battery, which requires proper maintenance to ensure a longer lifespan. Here are some tips on how you can maximize the lifespan of your electric vehicle's power battery: 1. Avoid extreme temperatures: The performance and lifespan of your EV's power battery can be significantly affected by extreme temperatures. Both high and low temperatures can cause damage to the battery cells, leading to reduced capacity and shorter lifespan. Therefore, it is essential to store and operate your EV within moderate temperature ranges whenever possible. 2. Maintain proper charging habits: Proper charging habits play a crucial role in maximizing the lifespan of your EV's power battery. It is recommended to maintain a moderate state of charge (SOC) and avoid frequent deep discharges and full charges. 3. Regular maintenance: Regular maintenance is essential for ensuring the longevity of your EV's power battery. This includes monitoring the battery's health, checking for any signs of damage or leakage, and addressing issues promptly. 4. Drive efficiently: Driving efficiently can also help maximize the lifespan of your EV's power battery by reducing strain on the battery and improving overall energy efficiency.

**I accidentally deleted some items from my iCloud Drive, can I recover them ?

The article provides a step-by-step guide on how to recover accidentally deleted items from iCloud Drive, emphasizing the importance of acting within a 30-day window for potential recovery. It highlights key actions such as accessing the iCloud website, navigating to iCloud Drive, checking the "Recently Deleted" folder, selecting files for recovery, initiating the recovery process, and verifying the restoration of files. Additionally, it underscores the necessity of having sufficient storage space and maintaining regular backups to prevent future data loss incidents.

What is single motor drive ?

Single motor drive is a type of electric drive system that uses one motor to power a machine or device, offering efficiency, precision, simplicity, flexibility, and reliability. It has numerous applications across various industries, such as manufacturing, transportation, robotics, HVAC, and agriculture.

How does a single motor drive work ?

The motor drive converts incoming AC power to DC, controls the motor's speed via PWM, regulates its torque by monitoring current and adjusting voltage, and ensures proper operation through feedback control.

How does a multi-motor drive system work ?

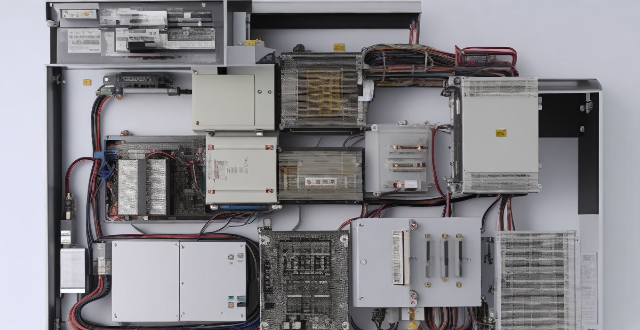

The text explains how a multi-motor drive system works, its components, and benefits. It describes the process of power conversion, control signals, motor operation, mechanical transmission, and feedback adjustment in such systems. The advantages include improved efficiency, increased redundancy, and enhanced control.

How does a lithium-ion power battery work ?

Lithium-ion power batteries work through the movement of lithium ions between the anode and cathode during charging and discharging, generating an electrical current to power devices. The process involves intercalation and deintercalation of ions in the electrodes, facilitated by an electrolyte and separator. Safety mechanisms and lifespan are key considerations for these widely used batteries.

In what industries are drive motors most commonly used, and why ?

Drive motors are crucial across industries for efficiency, reliability, and precision. In transportation, they power vehicles, aircraft, and railways. Manufacturing uses them in robotics, machinery, and printing. Construction and agriculture rely on them for heavy equipment and farm machinery. Consumer products like appliances and power tools also use drive motors, as do medical devices and prosthetics. Their significance lies in efficient energy conversion, reliable performance, and precise operation.

How much power can a hub motor generate ?

Hub motors are electric motors built into the wheel's hub and are commonly found in electric vehicles, wheelchairs, and other space-limited applications. The power generation of a hub motor is influenced by its design, size, and the type of battery it uses. Larger motors generally produce more power but require more energy to operate. The control system managing the motor's power output can also affect performance. Examples of hub motor power generation include small electric bikes (250-500 watts), medium electric bikes (500-1000 watts), large electric bikes (over 1000 watts), electric wheelchairs (250-1000 watts), and other applications like golf carts and electric cars with varying power ratings.

What are the benefits of using solar power ?

Solar power is a renewable and sustainable energy source that offers numerous benefits. It can be cost-effective in the long run, environmentally friendly, promotes energy independence, has low maintenance costs, versatile applications, creates jobs, provides government incentives, increases property value, and enhances energy security. As technology advances and awareness grows about renewable energy sources like solar power, its adoption is expected to continue rising worldwide.

How do women navigate power dynamics in relationships ?

In relationships, power dynamics often play a significant role, and understanding how to navigate them is crucial for maintaining healthy partnerships. Here's a detailed exploration of strategies women can use to manage power dynamics effectively: #### **Understanding Power Dynamics** Power dynamics refer to the distribution of influence, control, and authority within a relationship. It's important to recognize that power imbalances can manifest in various forms, such as financial disparity, differences in social status, educational background, or even emotional control. ##### **Key Points to Consider:** - **Awareness:** Recognize when power imbalances are present. - **Equality:** Work towards an equal distribution of power. - **Communication:** Open dialogue about each other's needs and expectations. #### **Strategies for Navigating Power Dynamics** 1. **Open Communication** - Start by discussing your feelings and expectations openly. - Use "I" statements to express yourself without accusing or blaming. - Encourage your partner to do the same. 2. **Setting Boundaries** - Identify what you find acceptable and unacceptable in a relationship. - Clearly communicate these boundaries to your partner. - Respect each other's boundaries equally. 3. **Shared Decision-Making** - Make decisions together rather than one person making all the choices. - Discuss options and consider each other's opinions and preferences. - Resolve conflicts collaboratively. 4. **Financial Independence** - Aim for financial independence where possible. - Discuss money matters transparently and work towards joint financial goals. - Avoid financial dependence on a partner to maintain negotiating power. 5. **Personal Growth and Self-Improvement** - Invest in your own education and career development. - Pursue hobbies and interests outside of the relationship. - Maintain a strong support network of friends and family. 6. **Recognizing and Addressing Manipulation** - Be aware of manipulation tactics such as guilt-tripping, silent treatments, or gaslighting. - Address these behaviors immediately and firmly. - Seek help from a counselor if needed. 7. **Mutual Respect** - Treat each other with respect at all times. - Avoid belittling or undermining your partner, even in arguments. - Acknowledge each other's achievements and contributions. 8. **Seeking Support** - Don't hesitate to seek advice from trusted friends, family, or professionals. - Attend workshops or read literature on healthy relationships. - Consider couples counseling if issues persist. #### **Conclusion** Navigating power dynamics in relationships requires a conscious effort to maintain equality, respect, and open communication. By employing strategies like setting clear boundaries, fostering shared decision-making, and encouraging personal growth, women can ensure their voices are heard and their needs are met within their relationships. It's essential to address any signs of unhealthy power dynamics promptly and to seek support when necessary to preserve a balanced and fulfilling partnership.

Can a combination motor drive improve energy efficiency in my facility ?

Combination motor drives can improve energy efficiency in facilities by optimizing electric motor performance, reducing energy consumption, and extending equipment lifespan. They offer variable speed control, soft start/stop capabilities, and reactive power compensation features that contribute to lower energy bills, reduced maintenance costs, and environmental benefits like reduced greenhouse gas emissions.

Can you explain the differences between AC and DC drive motors ?

Electric motors are essential components in various industries, ranging from manufacturing to transportation. Two of the most common types of electric motors are AC (Alternating Current) and DC (Direct Current) drive motors. While both serve similar functions, there are several differences between them that affect their performance and applications. AC and DC drive motors differ in their construction and design, with AC motors having a simpler design with fewer parts, while DC motors have more complex designs with additional components such as brushes and commutators. This complexity can lead to higher maintenance costs for DC motors compared to AC motors. One of the main differences between AC and DC drive motors is their ability to control speed. AC motors generally operate at a fixed speed, which makes them less suitable for applications requiring variable speed control. On the other hand, DC motors offer precise speed control, making them ideal for applications such as robotics, CNC machines, and conveyor systems. AC motors are generally more efficient than DC motors due to their simpler design and lower power consumption. However, the efficiency of a motor also depends on its size, load capacity, and operating conditions. In some cases, DC motors may be more energy-efficient when used in low-power applications or when precise speed control is required. Another difference between AC and DC drive motors is their starting torque. AC motors generally have a higher starting torque than DC motors, which makes them better suited for heavy-duty applications such as pumps, fans, and compressors. DC motors, on the other hand, provide a smoother start-up but may require additional components to achieve the desired starting torque. The cost and availability of AC and DC drive motors vary depending on their size, type, and manufacturer. Generally, AC motors are more widely available and less expensive than DC motors due to their simpler design and lower production costs. However, the total cost of ownership should also consider factors such as maintenance, repair, and energy consumption over the motor's lifetime.