Motor Electric

Can a speed controller be used to control the speed of an electric motor ?

A speed controller is a device that adjusts the electrical power supplied to an electric motor to change its speed. There are several types of speed controllers available for electric motors, including variable frequency drives (VFDs), DC motor controllers, and phase controllers. Using a speed controller has benefits such as energy efficiency, improved performance, extended motor lifespan, and enhanced safety.

How does a Series Hybrid Electric Vehicle work ?

A series hybrid electric vehicle (SHEV) is a type of hybrid car that utilizes two power sources: an internal combustion engine (ICE) and an electric motor. The ICE generates electricity to charge the battery pack, which in turn powers the electric motor to propel the vehicle. The main components of a series hybrid electric vehicle include the ICE, battery pack, and electric motor. The working process of a series hybrid electric vehicle involves starting the vehicle with the electric motor drawing power from the battery pack, driving at low speeds or during city driving using only the electric motor, increasing speed or accelerating by starting up the ICE to generate electricity and charge the battery pack, regenerative braking to convert kinetic energy into electrical energy and store it in the battery pack, charging the battery pack when its state of charge falls below a certain level, steady-state driving on highways with the ICE running at its optimal speed while the electric motor provides necessary power, and shutting down both the ICE and electric motor when the vehicle is turned off. Series hybrid electric vehicles offer benefits such as improved fuel efficiency, lower emissions, reduced wear and tear on the ICE, and regenerative braking.

How much power can a hub motor generate ?

Hub motors are electric motors built into the wheel's hub and are commonly found in electric vehicles, wheelchairs, and other space-limited applications. The power generation of a hub motor is influenced by its design, size, and the type of battery it uses. Larger motors generally produce more power but require more energy to operate. The control system managing the motor's power output can also affect performance. Examples of hub motor power generation include small electric bikes (250-500 watts), medium electric bikes (500-1000 watts), large electric bikes (over 1000 watts), electric wheelchairs (250-1000 watts), and other applications like golf carts and electric cars with varying power ratings.

How does a parallel hybrid electric vehicle (PHEV) work ?

Parallel hybrid electric vehicles (PHEVs) are a type of hybrid vehicle that combines an internal combustion engine (ICE) with an electric motor. The two power sources can work independently or together, depending on the driving conditions. PHEVs have three operating modes: ICE only, electric motor only, and combined power. The energy management system controls the operation of the ICE and electric motor, deciding which power source to use based on driving conditions, battery state of charge, and other factors. PHEVs offer benefits such as improved fuel efficiency, reduced emissions, tax incentives, and reduced dependence on fossil fuels.

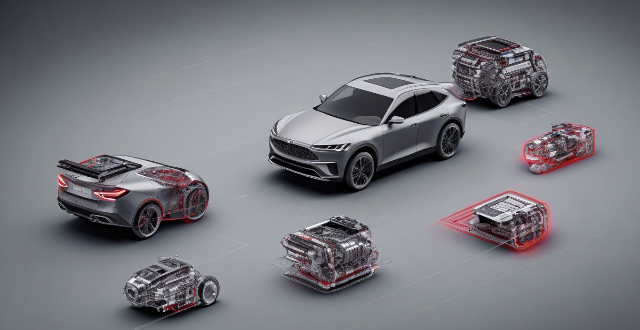

What are the advantages and disadvantages of multi-motor drives in electric vehicles ?

Multi-motor drives in electric vehicles provide enhanced performance, efficiency, redundancy, and design flexibility. However, they also come with increased complexity, cost, battery drain, weight, space constraints, and control challenges. The decision to use a multi-motor system should consider these factors based on the vehicle's goals and requirements.

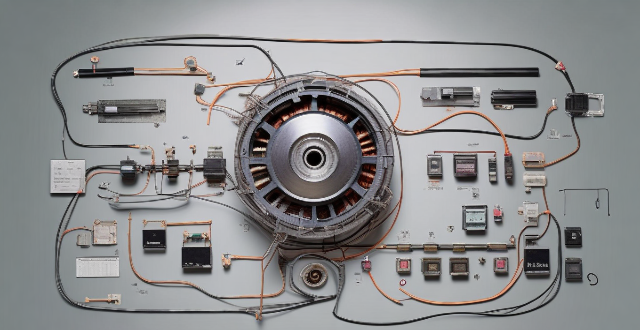

What is a hub motor ?

A hub motor is an electric motor integrated into a vehicle's wheel hub, offering direct drive, simplified design, quiet operation, and space efficiency. However, it has limitations such as limited power output, overheating concerns, and cost considerations. Hub motors are commonly used in electric vehicles like bicycles, scooters, motorcycles, and cars.

What is a Series Hybrid Electric Vehicle (SHEV) ?

A Series Hybrid Electric Vehicle (SHEV) is a type of hybrid vehicle that uses an internal combustion engine and an electric motor to power the wheels. The engine generates electricity to charge the battery pack or provide power to the electric motor, which then drives the wheels. Some SHEVs have regenerative braking systems that capture energy during braking and use it to recharge the battery pack. Advantages of a SHEV include improved fuel economy, reduced emissions, increased torque, and quiet operation. Disadvantages include complexity, weight, limited range, and higher cost.

How efficient is a Series Hybrid Electric Vehicle ?

Series hybrid electric vehicles (SHEVs) combine internal combustion engines and electric motors to power wheels, offering efficiency benefits through regenerative braking, engine optimization, and electric drive. However, added weight, system complexity, and battery depletion can be drawbacks. The efficiency of SHEVs hinges on design and driving habits.

Can you provide some examples of applications where multi-motor drives are used ?

Multi-motor drives are used in various applications where multiple motors need to be controlled simultaneously, including industrial automation, CNC machines, electric vehicles, wind turbines, robotics, and aerospace.

How do electric car batteries work ?

Electric car batteries are the powerhouse of electric vehicles (EVs). Here's a detailed explanation: 1. Basics of an Electric Car Battery 2. Charging Process 3. Discharging Process (Driving the Car) 4. Battery Management System (BMS) 5. Benefits and Challenges

How does a single motor drive work ?

The motor drive converts incoming AC power to DC, controls the motor's speed via PWM, regulates its torque by monitoring current and adjusting voltage, and ensures proper operation through feedback control.

How does an electric car work ?

Electric cars, or EVs, are powered by electricity stored in a battery pack, which is used to power an electric motor that turns the wheels. The process includes starting the car with power from the battery to the controller, which then sends electricity to the motor for acceleration. Braking involves regenerative braking that captures energy to recharge the battery. Charging the battery requires plugging into an external power source managed by an onboard charger. Electric cars boast higher energy efficiency, lower operating costs, reduced environmental impact, quieter operation, and simpler maintenance compared to traditional gasoline vehicles.

How does a multi-motor drive system work ?

The text explains how a multi-motor drive system works, its components, and benefits. It describes the process of power conversion, control signals, motor operation, mechanical transmission, and feedback adjustment in such systems. The advantages include improved efficiency, increased redundancy, and enhanced control.

Can a combination motor drive improve energy efficiency in my facility ?

Combination motor drives can improve energy efficiency in facilities by optimizing electric motor performance, reducing energy consumption, and extending equipment lifespan. They offer variable speed control, soft start/stop capabilities, and reactive power compensation features that contribute to lower energy bills, reduced maintenance costs, and environmental benefits like reduced greenhouse gas emissions.

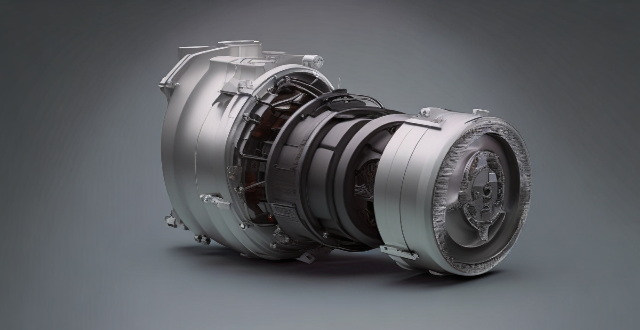

What is an internal rotor motor ?

The text discusses the design, advantages, disadvantages, and applications of internal rotor motors. Internal rotor motors are a type of electric motor where the moving part (rotor) is inside the stationary part (stator). They offer benefits such as high efficiency, good heat dissipation, simplicity in construction, and low inertia. However, they also have limitations like limited torque density, difficulty in cooling, and potential for magnetic saturation. These motors are commonly used in automotive, aerospace, industrial equipment, and consumer electronics applications.

How does a combination motor drive work ?

Combination motor drives integrate VFD and servo controller functionalities to achieve precise speed and torque control for AC induction and permanent magnet synchronous motors. They enhance performance, reduce energy consumption, and extend motor lifespan by offering smooth speed control and reducing wear and tear. Key components include a VFD, servo controller, electric motor, encoder, and user interface. The system uses feedback from an encoder to adjust the motor's input signals, ensuring accurate motion profiles.

Can hub motors be used in bicycles ?

Hub motors, built into the wheel's hub, are compact and lightweight, making them suitable for bicycles. They offer easy installation, quiet operation, and low maintenance but may have limited power output and reduced range. Hub motors are designed for specific wheel sizes and can be more expensive than other electric motors. Despite some disadvantages, they are a popular choice for DIY e-bike projects and those seeking electric power assistance without sacrificing performance or handling characteristics.

How does a Series Hybrid Electric Vehicle compare to a Parallel Hybrid Electric Vehicle ?

Comparison between Series Hybrid Electric Vehicle and Parallel Hybrid Electric Vehicle highlights the differences in power transmission, battery dependency, fuel efficiency, performance, cost, complexity, and regenerative braking capabilities of both types. The series hybrid is more efficient for city driving, while the parallel hybrid suits highway driving better. The choice depends on the user's driving habits and needs, with both offering environmental and economic benefits over traditional vehicles.

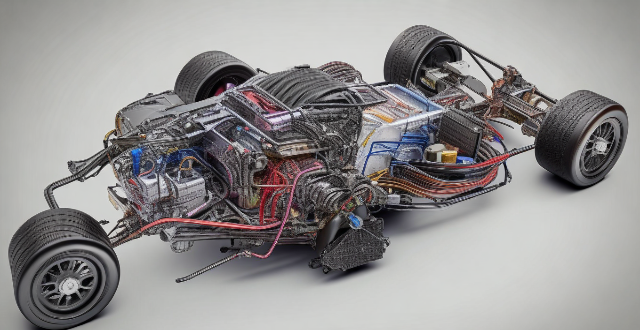

What are the key components of a Series Hybrid Electric Vehicle ?

Key components of a series hybrid electric vehicle (SHEV) include the battery pack, electric motor, internal combustion engine (ICE), generator, transmission, control unit, and regenerative braking system. The battery pack stores energy from the ICE or regenerative braking system and provides it to the electric motor when needed. The electric motor drives the wheels of the vehicle, while the ICE generates electricity to charge the battery pack rather than directly powering the wheels. The generator converts mechanical energy from the ICE into electrical energy to charge the battery pack. The transmission transfers power from the electric motor to the wheels using a single-speed reduction gearbox. The control unit manages the flow of energy between the various components and optimizes their operation. Finally, the regenerative braking system captures energy lost during braking and uses it to recharge the battery pack, increasing fuel efficiency and extending the range of the vehicle.

Are parallel hybrid electric vehicles (PHEVs) environmentally friendly ?

Parallel hybrid electric vehicles (PHEVs) are a type of hybrid vehicle that combines an internal combustion engine with an electric motor. While PHEVs have the potential to be more environmentally friendly than traditional gasoline-powered vehicles, their actual environmental impact depends on several factors, including the source of electricity used to charge the battery, the efficiency of the vehicle's components, and the driving habits of the user. One of the main benefits of PHEVs is their ability to reduce emissions compared to traditional gasoline-powered vehicles. By using both an electric motor and an internal combustion engine, PHEVs can achieve better fuel efficiency and lower emissions than conventional cars. However, the environmental impact of PHEVs also depends on how the battery is charged. If the electricity used to charge the battery comes from renewable sources such as solar or wind power, then the environmental benefits are even greater. On the other hand, if the electricity comes from coal-fired power plants or other non-renewable sources, then the overall environmental benefit may be reduced. Another factor that affects the environmental friendliness of PHEVs is the efficiency of their components. The more efficient the electric motor, battery, and internal combustion engine, the less energy they require to operate, which reduces their environmental impact. Manufacturers are constantly working to improve the efficiency of these components, which will help make PHEVs even more environmentally friendly in the future. Finally, the environmental impact of PHEVs also depends on how they are driven. If a driver primarily uses the electric motor for short trips around town and rarely uses the internal combustion engine, then the vehicle's overall environmental impact will be lower. On the other hand, if a driver frequently uses the internal combustion engine for long trips at high speeds, then the environmental benefits may be less significant. In conclusion, while parallel hybrid electric vehicles (PHEVs) have the potential to be more environmentally friendly than traditional gasoline-powered vehicles, their actual environmental impact depends on several factors. By taking these factors into account and making informed choices about how we use our vehicles, we can help reduce our impact on the environment and create a more sustainable future.

What maintenance is required for a hybrid car ?

Maintaining a hybrid car involves regular checks on the battery health and cooling system, brake inspections, tire care, engine oil changes, coolant flushes, electric motor lubrication, transmission fluid checks, and adhering to scheduled services. Proper maintenance ensures the longevity of high-value components like the battery and electric motor, contributing to improved fuel economy and reduced emissions.

What are the key components of a CHEV's drive system ?

The key components of a CHEV's drive system include the engine, electric motor, transmission, battery pack, and energy management system. The engine generates the majority of the power needed to propel the vehicle, while the electric motor provides additional power during acceleration or hill climbing. The transmission transfers power from the engine and electric motor to the wheels, and may be a conventional automatic or manual transmission or a specialized hybrid transmission. The battery pack stores electrical energy generated by the electric motor during regenerative braking and provides power to the electric motor when needed. The energy management system controls the flow of energy between the engine, electric motor, and battery pack, determining when to use each source of power based on driving conditions, state of charge of the battery, and driver demand. These components work together to provide a seamless driving experience while maximizing fuel efficiency and reducing emissions.

What are the benefits of a single motor drive in electric vehicles ?

The text discusses the benefits of a single motor drive in electric vehicles, including simplified design, lightweight construction, improved efficiency, lower cost, easier maintenance, and better packaging.

Can you drive a hybrid car in electric mode only ?

Hybrid cars offer the fuel efficiency of electric vehicles and the range of gasoline-powered cars. Some hybrids can drive in electric mode under certain conditions, such as battery charge level and speed. Advantages include reduced emissions and a quieter driving experience, but there are also drawbacks like limited range and slower acceleration. Examples include the Toyota Prius and Honda Insight.

What is the driving range of a Series Hybrid Electric Vehicle ?

The driving range of a Series Hybrid Electric Vehicle (SHEV) is influenced by factors such as battery pack size, electric motor efficiency, and vehicle weight. Most SHEVs have a combined driving range of around 30-50 miles per gallon equivalent (MPGe), but actual range may vary due to factors like driving conditions and use of accessories. Proper maintenance and consideration of these factors can help maximize the fuel efficiency and environmental benefits of a SHEV.

How does a brushless motor work ?

Brushless motors, also known as BLDC motors, are electric motors that use an electronic controller to switch the current in their stator windings. They consist of three main components: the rotor, stator, and electronic controller. The working principle of a brushless motor involves initial rotation, commutation, and maintaining rotation. Brushless motors offer several advantages over traditional brushed motors, including higher efficiency, longer lifespan, better performance, and lower maintenance.

What are some popular diesel hybrid car models ?

Diesel hybrid cars are becoming increasingly popular due to their fuel efficiency and lower emissions. Here are some of the most popular diesel hybrid car models: The Audi A3 TDI e-tron is a compact luxury car that combines a 2.0-liter TDI diesel engine with an electric motor. It offers up to 150 horsepower and can travel up to 31 miles on electric power alone. The Volkswagen Jetta TDI Hybrid is a midsize sedan that features a 1.6-liter TDI diesel engine paired with an electric motor. It provides excellent fuel economy and low emissions, making it an ideal choice for environmentally conscious drivers. The Peugeot 308 HDi Hybrid is a compact hatchback that combines a 1.6-liter HDi diesel engine with an electric motor. It offers impressive fuel economy and reduced CO2 emissions, while still providing plenty of power and performance. The Skoda Octavia iV is a spacious family car that features a 2.0-liter TDI diesel engine combined with an electric motor. It offers up to 240 horsepower and can travel up to 37 miles on electric power alone, making it a great option for long trips. The Volkswagen Passat TDI Hybrid is a midsize sedan that combines a 2.0-liter TDI diesel engine with an electric motor. It provides excellent fuel economy and low emissions, while also offering plenty of space and comfort for passengers.

How does a hybrid car work ?

A hybrid car uses a combination of an internal combustion engine and electric motors to achieve better fuel economy and reduced emissions. It consists of key components like the ICE, electric motor(s), battery pack, transmission, control unit, and a charging system that includes regenerative braking. The car operates in various modes: starting with the electric motor, driving with either or both power sources, using regenerative braking for efficiency and battery charging, minimizing idling by shutting down the ICE at stops, and managing the battery's state of charge and health. Benefits include improved gas mileage, lower emissions, enhanced performance, and reduced wear and tear on vehicle components.

How do electric cars compare to hybrid cars ?

Electric cars run solely on electricity and produce zero emissions, while hybrid cars combine a gasoline engine with an electric motor for improved fuel efficiency. Electric cars offer environmental benefits and lower operating costs but have limited range and long charging times. Hybrids provide a balance between gasoline-powered vehicles and electric cars, with improved fuel efficiency and no range limitations but still rely on gasoline and produce emissions. The choice between the two often depends on individual needs and preferences.

What is a brushless motor ?

Brushless motors, also known as BLDC (Brushless Direct Current) motors, are electric motors that use an electronic controller to switch the current in their stator windings. They have higher efficiency, longer lifespan, higher power density, lower maintenance requirements, and quieter operation compared to brushed motors. The working principle of a brushless motor involves three main components: the rotor, stator, and electronic controller. Brushless motors are used in various applications, including aircraft, automotive, appliances, and industrial equipment.