Motor Drive

How does a single motor drive compare to a dual motor drive ?

This article compares single motor drives and dual motor drives based on their performance, efficiency, cost, and applications. Single motor drives can only control one motor at a time, while dual motor drives can control two motors simultaneously. Dual motor drives offer higher overall torque and better synchronization between multiple motors, but they also consume more power and require more maintenance. Single motor drives are typically less expensive and well-suited for low power applications with simple movement profiles, while dual motor drives are appropriate for high power applications with complex movement profiles requiring precise synchronization. The choice between a single motor drive and a dual motor drive depends on the specific requirements of the application.

What are the advantages and disadvantages of using a combination motor drive compared to a single motor drive ?

The combination motor drive has several advantages over a single motor drive, including improved performance, enhanced reliability, flexibility in design, energy efficiency, and modularity and scalability. However, it also has disadvantages such as complexity, cost, space requirements, synchronization issues, and integration challenges.

What are the benefits of using a combination motor drive system ?

Combination motor drive systems offer benefits such as improved efficiency, increased reliability, flexibility, and enhanced control. These systems combine the advantages of different types of motors to create a more efficient and reliable drive system. They are ideal for a wide range of applications and can help businesses save money on energy costs while reducing downtime and maintenance requirements.

How do I choose the right drive motor for my application ?

When selecting a drive motor for your application, considerWhen selecting a drive motor for your application, considerrque and speed, power duty cycle, cost, size, control compatibility, safety compliance, maintenance, and manufacturer reputation. This comprehensive guide helps ensure you choose a motor that meets your needs effectively and efficiently.

What are the advantages of using a single motor drive system ?

A single motor drive system is a type of electric motor control system that uses only one motor to power a machine or equipment. This system has several advantages over other types of drive systems, including simplified design and maintenance, improved efficiency and performance, increased reliability and longevity, and greater flexibility and versatility. These benefits make it an attractive option for many industrial applications where precise control and efficient operation are essential.

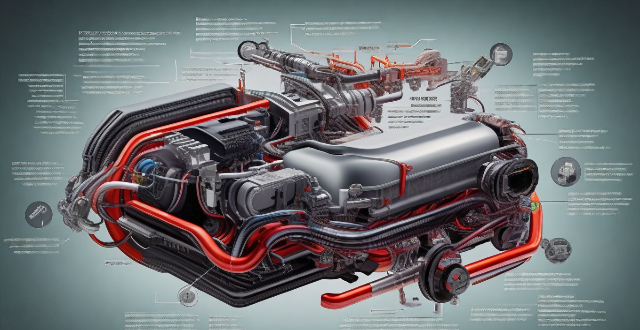

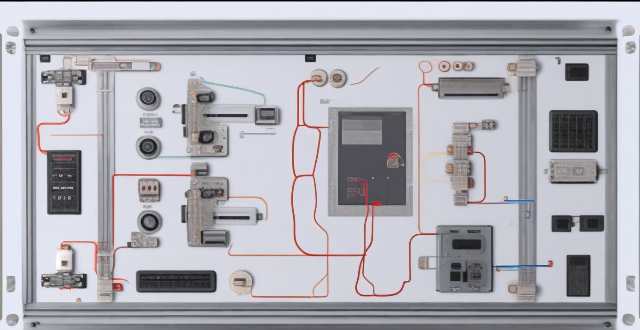

How do I install and maintain a combination motor drive system ?

A combination motor drive system, also known as an integrated drive system or hybrid drivetrain, is a complex assembly of components designed to deliver power from the engine to the wheels of a vehicle. It typically includes an internal combustion engine, one or more electric motors, and a transmission that may incorporate both mechanical and electronic control systems. This guide will walk you through the installation and maintenance process for such a system.

Is it possible to upgrade a machine to a single motor drive ?

The text discusses the possibility of upgrading a machine to a single motor drive. It outlines key considerations such as compatibility, performance requirements, and cost considerations. It also provides steps for upgrading to a single motor drive, including evaluating the machine, selecting a suitable motor drive, modifying the machine, installing the motor drive, and testing and optimizing the machine.

What is the difference between single motor and multi-motor drives ?

Single motor drives control only one motor and are simple, cost-effective, and easy to maintain. Multi-motor drives control multiple motors simultaneously and offer increased flexibility, improved performance, and enhanced functionality but are more complex and expensive. The choice between these two types of drives depends on the specific requirements of the application.

What are the challenges faced when designing a multi-motor drive system ?

The article discusses the challenges of designing a multi-motor drive system, including coordination between motors, power distribution, and synchronization. It emphasizes the importance of control algorithms, communication systems, mechanical design, efficiency optimization, power management, thermal management, timing control, feedback mechanisms, and mechanical design in achieving proper operation of the system. The article concludes that careful consideration of these factors is crucial for creating efficient and effective multi-motor drive systems.

How can I choose the right combination motor drive for my application ?

When selecting a combination motor drive for your application, consider factors such as the type of motor (AC, DC, stepper, or servo), application requirements (load characteristics, speed and torque needs, control precision), appropriate drive technology (VFDs, electronic speed controls, stepper motor drives, servo amplifiers), compatibility and integration with existing systems, performance features (efficiency, dynamic response, protection features), budget and cost considerations (initial and operating costs), and seek professional advice from manufacturers and technical support.

How does a single motor drive work ?

The motor drive converts incoming AC power to DC, controls the motor's speed via PWM, regulates its torque by monitoring current and adjusting voltage, and ensures proper operation through feedback control.

What are the key factors to consider when designing a combination motor drive system ?

Designing a combination motor drive system requires careful consideration of several key factors, including load requirements, efficiency and performance, control strategies, reliability and safety, and environmental considerations. Load requirements play a significant role in determining the type and size of the motor required for the drive system, while efficiency and performance are critical factors to consider when designing a motor drive system. Control strategies used in the motor drive system are also crucial, with common strategies including open-loop control, closed-loop control, and adaptive control. Reliability and safety are essential factors to consider when designing a motor drive system, with redundancy, fault detection and protection, and safety interlocks being key considerations. Finally, environmental considerations should also be taken into account when designing a motor drive system, with temperature, humidity, vibration, and shock loads being important factors to consider.

What are the advantages of using a drive motor in industrial equipment ?

Drive motors are crucial components in industrial equipment, offering advantages such as increased efficiency, improved accuracy and precision, flexibility and customization, reduced maintenance and downtime, enhanced safety, and environmental benefits. By optimizing processes for maximum productivity and energy savings, drive motors lead to reduced operating costs and increased profitability for businesses. They also provide precise control over machinery movements, allowing for accurate positioning and repeatable operations, which is particularly important in applications where precision is critical. Drive motors offer flexibility in adjusting the speed, direction, and torque of machinery, accommodating changes and meeting specific requirements. Modern drive motors are designed with reliability and durability, minimizing downtime and increasing productivity. They can also be equipped with safety features to prevent accidents and injuries. Finally, drive motors have positive environmental impacts by improving efficiency and reducing energy consumption, leading to reduced greenhouse gas emissions and less waste material produced during manufacturing processes.

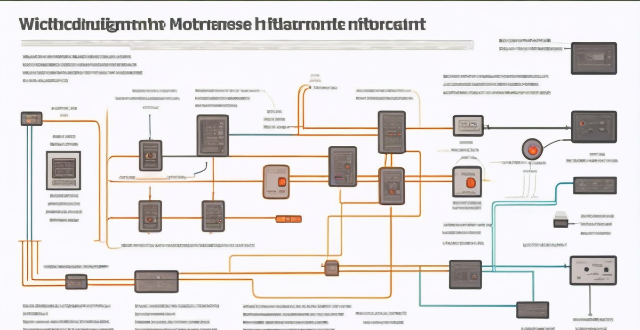

How does a multi-motor drive system work ?

The text explains how a multi-motor drive system works, its components, and benefits. It describes the process of power conversion, control signals, motor operation, mechanical transmission, and feedback adjustment in such systems. The advantages include improved efficiency, increased redundancy, and enhanced control.

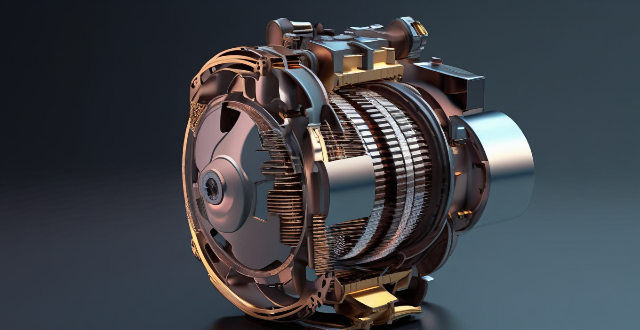

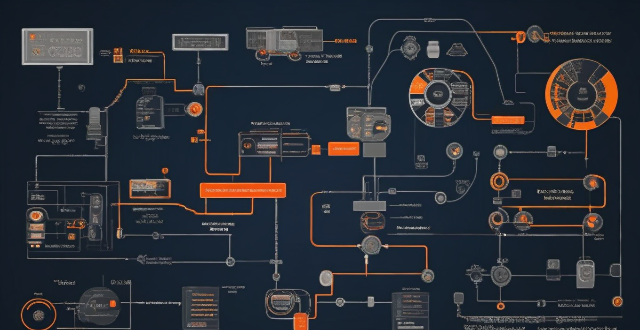

How does a combination motor drive work ?

Combination motor drives integrate VFD and servo controller functionalities to achieve precise speed and torque control for AC induction and permanent magnet synchronous motors. They enhance performance, reduce energy consumption, and extend motor lifespan by offering smooth speed control and reducing wear and tear. Key components include a VFD, servo controller, electric motor, encoder, and user interface. The system uses feedback from an encoder to adjust the motor's input signals, ensuring accurate motion profiles.

Can a combination motor drive improve energy efficiency in my facility ?

Combination motor drives can improve energy efficiency in facilities by optimizing electric motor performance, reducing energy consumption, and extending equipment lifespan. They offer variable speed control, soft start/stop capabilities, and reactive power compensation features that contribute to lower energy bills, reduced maintenance costs, and environmental benefits like reduced greenhouse gas emissions.

How does a multi-motor drive system contribute to energy savings in industrial processes ?

A multi-motor drive system contributes to energy savings in industrial processes by optimizing the operation of multiple motors. It balances loads, controls speed optimally, provides reactive power compensation, enables regenerative braking, and reduces maintenance costs. This technology helps businesses improve their bottom line while reducing their environmental footprint.

How do hub motors compare to mid-drive motors ?

Electric bicycle motors come in two primary configurations: hub motors and mid-drive motors, each with unique characteristics, advantages, and disadvantages suitable for different riding styles and preferences. Hub motors are integrated directly into the bicycle wheel hub, while mid-drive motors are mounted in the center of the bicycle, near the bottom bracket. Hub motors are generally simpler to install and maintain, quieter, and less expensive than mid-drive motors but are less efficient at higher speeds and can affect bike handling due to changes in wheel diameter and weight distribution. Mid-drive motors offer more efficient power delivery at higher speeds, better weight distribution, and adaptability to various wheel sizes but are generally more complex to install and maintain, louder during operation, and more expensive. Choosing between a hub motor and a mid-drive motor depends on what you value most in an e-bike, such as simplicity, quiet operation, lower cost, efficiency at higher speeds, better weight distribution, or adaptability.

How do I maintain and troubleshoot a drive motor ?

Maintaining and troubleshooting a drive motor is crucial for ensuring its longevity and optimal performance. Here are some tips on how to do it: ### Maintenance Tips 1. Keep the motor clean by removing dust, dirt, and debris from the exterior and interior components. This helps prevent overheating and damage to the motor. 2. Ensure that the motor bearings are properly lubricated to reduce friction and wear. Follow the manufacturer's recommendations for the type and frequency of lubrication. 3. Check the cooling system (if applicable) regularly to ensure it is functioning correctly. Clean or replace filters as needed to maintain proper airflow. 4. Inspect electrical connections for signs of corrosion, damage, or looseness. Tighten or replace connections as necessary to prevent electrical issues. 5. Monitor the voltage and amperage of the motor to ensure they are within the recommended range. Excessive voltage or amperage can cause damage to the motor. 6. Ensure that thermal protection devices are functioning correctly to prevent overheating and potential damage to the motor. 7. Conduct periodic inspections of the motor, including checking for unusual noises, vibrations, or smells. Address any issues promptly to avoid further damage. ### Troubleshooting Tips If you encounter issues with your drive motor, here are some troubleshooting steps to follow: 1. Ensure that the motor is receiving the correct voltage and amperage. A faulty power supply can cause the motor to malfunction or fail. 2. Check for loose, damaged, or corroded wiring connections. Repair or replace any faulty wiring to restore proper functionality. 3. If you hear unusual noises coming from the motor, such as grinding or humming, it could indicate a problem with the bearings or other internal components. Consult a professional mechanic for further diagnosis and repair. 4. If the motor is overheating, check the cooling system for any blockages or issues with airflow. Clean or replace filters as needed to improve cooling efficiency. 5. Test thermal protection devices to ensure they are functioning correctly. Faulty devices may not provide adequate protection against overheating, leading to motor damage. 6. If you are unable to identify or resolve the issue, consult the manufacturer's guide or contact their support team for assistance. They may be able to provide additional troubleshooting steps or recommend a professional mechanic for further inspection and repair. By following these maintenance and troubleshooting tips, you can help ensure the longevity and optimal performance of your drive motor. Remember to always prioritize safety when working on any machinery and seek professional assistance if necessary.

Are there any safety concerns associated with using a combination motor drive ?

The text discusses the safety concerns associated with using combination motor drives, which combine the functions of an electric motor and a gearbox. Safety issues include electrical hazards such as overheating and electrical shock, mechanical hazards like gearbox failure and injuries from rotating parts, and chemical hazards from lubricants and fluids. To ensure safe operation, it is important to follow proper safety procedures, regularly maintain the equipment, and use appropriate personal protective equipment.

What are the different types of combination motor drives available in the market ?

The article discusses different types of combination motor drives, including AC, DC, servo, and stepper motor drives. It highlights their unique features such as precise speed control, high torque output, regenerative braking, position control, feedback systems, and microstepping capabilities. The article emphasizes the importance of selecting the appropriate type of motor drive based on the specific needs and requirements of the application.

What are the maintenance requirements for a single motor drive system ?

Maintenance requirements for a single motor drive system include daily visual and auditory inspections, weekly lubrication and cleanliness checks, monthly electrical connection and belt tension inspections, quarterly cooling system cleaning and bearing lubrication, yearly motor performance testing and preventative replacement of parts, additional environmental factor considerations, and following manufacturer's guidelines for maintenance and servicing.

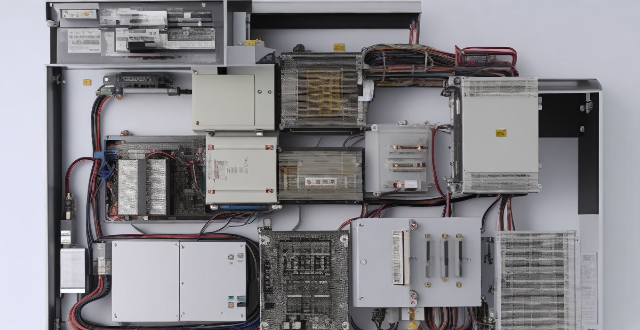

How has the development of power electronics influenced the design of modern drive motors ?

The advancement of power electronics has significantly influenced the design and performance of contemporary drive motors. This technological progress has led to more efficient, reliable, and sophisticated motor control systems, offering a wide array of benefits across various sectors. Here are some key points: - **Enhanced Efficiency and Performance**: Power electronics have enabled advanced control techniques like FOC and DTC, optimizing motor operation for better dynamic response and efficiency. The introduction of VFDs allows motors to operate at varying speeds without mechanical gearboxes or belt drives, enhancing energy efficiency and reducing mechanical wear. - **Improved Reliability and Durability**: Integrated power electronics can monitor motor conditions in real-time, enabling predictive maintenance that reduces downtime and repair costs. Modern drive motors often include protection features like overcurrent, overvoltage, and temperature monitoring, thanks to the integration of power electronics. These safeguards extend the motor's lifespan and ensure stable operation. - **Customizable and Smarter Motors**: Power electronics enable motors with programmable settings that can be tailored to specific applications, improving performance and adaptability. The inclusion of power electronics paves the way for IoT integration, where motors can communicate with other devices, enabling smart grid functionalities and remote diagnostics. - **Environmental Benefits**: By allowing motors to operate at optimal speeds and loads, power electronics contribute to significant energy savings, aligning with global efforts to reduce energy consumption and greenhouse gas emissions. Modern drive motors utilizing power electronics often operate more smoothly, resulting in reduced noise pollution compared to traditional motor designs. - **Scalability and Cost-Effectiveness**: Power electronic components can be designed modularly, making it easier to scale motor designs up or down to meet specific power requirements without starting from scratch. As power electronic components become more standardized and mass-produced, their cost decreases, making advanced motor designs more accessible to a broader range of industries and applications.

Can a single motor drive be used for heavy-duty tasks ?

A single motor drive can indeed be used for heavy-duty tasks, but it depends on several factors such as the type of motor, its power rating, and the nature of the task. There are various types of motors available, each with its own set of advantages and disadvantages. The power rating of a motor is an important factor to consider when determining whether it can handle heavy-duty tasks. The nature of the task is another critical factor to consider. By carefully considering these factors and choosing the right motor for the job, you can ensure that your system is reliable, efficient, and effective.

What is single motor drive ?

Single motor drive is a type of electric drive system that uses one motor to power a machine or device, offering efficiency, precision, simplicity, flexibility, and reliability. It has numerous applications across various industries, such as manufacturing, transportation, robotics, HVAC, and agriculture.

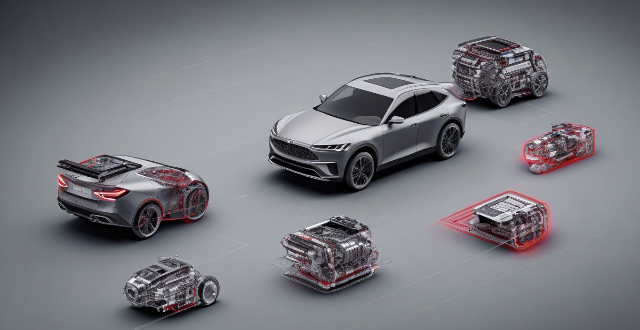

What are the advantages and disadvantages of multi-motor drives in electric vehicles ?

Multi-motor drives in electric vehicles provide enhanced performance, efficiency, redundancy, and design flexibility. However, they also come with increased complexity, cost, battery drain, weight, space constraints, and control challenges. The decision to use a multi-motor system should consider these factors based on the vehicle's goals and requirements.

What is a hub motor ?

A hub motor is an electric motor integrated into a vehicle's wheel hub, offering direct drive, simplified design, quiet operation, and space efficiency. However, it has limitations such as limited power output, overheating concerns, and cost considerations. Hub motors are commonly used in electric vehicles like bicycles, scooters, motorcycles, and cars.

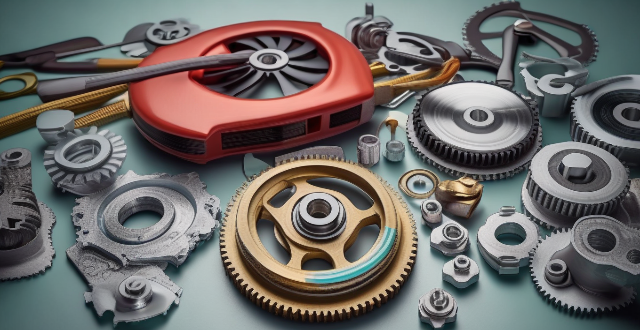

What is a drive motor and how does it work ?

A drive motor, also known as a motor or electric motor, is a device that converts electrical energy into mechanical energy. It operates on the principle of electromagnetism, using magnetic fields to produce motion. Drive motors are used in various applications such as transportation, industrial machinery, and consumer electronics. The working principle of a drive motor is based on **electromagnetic induction**, which refers to the process of generating an electric current within a conductor when it is exposed to a changing magnetic field. In a typical AC (Alternating Current) motor, a rotating magnetic field is created inside the motor using multiple coils of wire connected to an alternating current source. The alternating current causes the direction of the magnetic field produced by each coil to change continuously. As these fields change, they create a rotational force called **torque**, which turns the motor shaft. The interaction between the rotating magnetic field and the stationary part of the motor generates motion. This movement can be harnessed to perform work, such as driving a fan blade or lifting weights. The components of a drive motor include the stator, rotor, bearings, windings, commutator (in DC motors), and shaft. There are several types of drive motors, including DC Motors, AC Motors, Stepper Motors, and Servo Motors. Each type has its advantages and disadvantages, making it suitable for specific applications based on factors like efficiency, size, cost, and control complexity.

What are the benefits of using multi-motor drive systems ?

The benefits of using multi-motor drive systems include improved efficiency and performance, increased reliability and redundancy, and greater flexibility and scalability. These advantages make them an attractive option for many industrial applications where precise control and high reliability are critical.

What are the benefits of a single motor drive in electric vehicles ?

The text discusses the benefits of a single motor drive in electric vehicles, including simplified design, lightweight construction, improved efficiency, lower cost, easier maintenance, and better packaging.