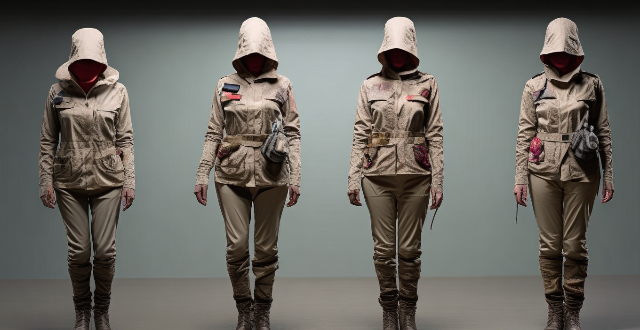

Use Protective

How should protective clothing be properly disposed of after use ?

Proper Disposal of Protective Clothing After Use: - Remove clothing carefully in a designated area to avoid cross-contamination. - Place used clothing in a sealable plastic bag and seal tightly. - Label the bag with "Biohazard" or "Contaminated" and include the date and time of disposal. - Dispose of the bag properly according to your organization's protocols or local waste management facility guidance. - Clean and disinfect the area where you removed your protective clothing. - Wash your hands thoroughly with soap and water for at least 20 seconds. - If exposed to a contagious disease, monitor for symptoms and seek medical attention if necessary.

What is the difference between disposable and reusable protective clothing ?

The article discusses the differences between disposable and reusable protective clothing in terms of their usage, durability, cost, and environmental impact. Disposable protective clothing is made from lightweight materials and designed for short-term use, while reusable protective clothing is made from more durable materials and designed for long-term use. The choice between the two depends on factors such as budget, frequency of use, and level of protection required.

How do safety regulations influence the use of protective equipment in the workplace ?

Safety regulations play a crucial role in ensuring that workers use protective equipment in the workplace. They enforce compliance by requiring employers to provide necessary protective equipment to their employees, mandate regular training sessions for workers about the importance of using protective equipment, conduct safety inspections periodically to ensure that protective equipment is up-to-date, functional, and used correctly, and drive continuous improvement based on new technologies, changing work environments, and lessons learned from incidents. These measures collectively create a safer work environment for all employees.

In what scenarios is it necessary to use chemical protective measures in an industrial setting ?

Industrial settings often require chemical protective measures to ensure worker safety. These scenarios include handling hazardous chemicals, working in confined spaces, performing maintenance on chemical process equipment, disposing of hazardous waste, and emergency response to chemical incidents. Workers must wear appropriate personal protective equipment (PPE) such as gloves, aprons, goggles, and respiratory protection devices to prevent exposure to harmful chemicals. Examples of these scenarios include manufacturing processes involving strong acids or bases, tank cleaning in the petrochemical industry, repairing valves or pipes in chemical processing plants, disposal of chemical waste at landfill sites, and firefighting and rescue operations during chemical fires or explosions. By implementing these chemical protective measures in relevant industrial scenarios, employers can help safeguard their employees from potential health hazards associated with chemical exposure.

How often should protective clothing be replaced or cleaned ?

Protective clothing is essential in various industries and situations to ensure the safety and health of workers. It is crucial to maintain the effectiveness of protective clothing by replacing or cleaning it regularly. The frequency of replacement or cleaning depends on various factors such as the type of protective clothing, level of exposure, manufacturer's recommendations, and personal hygiene. Disposable protective clothing should be replaced after each use, while reusable protective clothing can be cleaned and reused multiple times. Always follow the manufacturer's recommendations and maintain personal hygiene by changing into clean protective clothing when necessary. By doing so, you can ensure the effectiveness of protective clothing in preventing contamination and protecting workers from hazardous substances.

What are the most common materials used in the production of protective clothing ?

Protective clothing is designed to safeguard individuals from hazardous environments or conditions. The materials used for such garments play a crucial role in providing the necessary protection while ensuring comfort and functionality. In this article, we will explore the most common materials used in the production of protective clothing: Polyester, Cotton, Nylon, Neoprene, and Gore-Tex.

Can a protective iPhone case prevent damage from drops and falls ?

A protective iPhone case can significantly reduce the risk of damage from drops and falls by providing shock absorption, impact dispersion, raised edges, and durability. There are several types of protective cases available, including rubber, hard plastic, and hybrid cases. When choosing a protective case, consider the material, design, brand reputation, and price to ensure you get the best protection for your device.

What are the different types of protective clothing available ?

Protective clothing is essential in various industries and environments to ensure the safety and well-being of individuals. It is designed to protect against hazards such as chemicals, biological agents, radiation, heat, cold, electrical shocks, and physical injuries. There are different types of protective clothing available, including chemical protective clothing, biological protective clothing, radiation protective clothing, thermal protective clothing, electrical protective clothing, and physical protective clothing. Each type of protective clothing is designed to protect against specific hazards and includes a range of garments and accessories.

Is it necessary to wear protective gear when applying disinfectants in household settings ?

In conclusion, wearing protective gear when applying disinfectants in household settings is necessary to protect yourself from potential harm. Disinfectants contain chemicals that can be harmful if not used properly, and there are risks associated with their use. Personal Protective Equipment (PPE) such as gloves, goggles, masks, and protective clothing can help minimize these risks. While it may not be necessary to wear full PPE every time you clean your home, there are certain situations where it is recommended. It is always better to err on the side of caution and wear appropriate PPE when using disinfectants to ensure your safety and health.

How often should I replace my iPhone case to maintain its protective qualities ?

The article discusses the importance of replacing iPhone cases to maintain their protective qualities and suggests different intervals for various types of cases based on signs of wear and tear.

How do I choose the right personal protective equipment (PPE) for working with electricity ?

When working with electricity, it is crucial to choose the right personal protective equipment (PPE) to ensure your safety. Here are some guidelines to help you make the right choice: 1. Assess the risk level before choosing any PPE. 2. Choose appropriate footwear, such as insulated boots or shoes with non-conductive soles. 3. Wear insulating gloves, such as Class 00 or Class 1 gloves. 4. Use insulating tools and equipment, such as insulating wrenches and screwdrivers, mats, and barriers. 5. Wear protective clothing, such as flame-resistant clothing, long sleeve shirts, and long pants. 6. Use head protection, such as hard hats and face shields or safety goggles. 7. Follow the manufacturer's instructions when using PPE and ensure that all equipment is properly maintained and inspected regularly.

Can you explain the different levels of chemical resistance in protective clothing ?

Chemical resistance is a crucial aspect of protective clothing, especially for those working in hazardous environments. The level of chemical resistance required depends on the type and concentration of chemicals present in the work area. Here, we will discuss the different levels of chemical resistance in protective clothing: 1. Level A: Highest Level of Protection 2. Level B: Intermediate Level of Protection 3. Level C: Lower Level of Protection 4. Level D: Basic Protection

What are the benefits of wearing protective clothing in a laboratory setting ?

In a laboratory setting, wearing protective clothing is crucial for the safety and well-being of individuals working with hazardous materials or conducting experiments that may pose risks. The benefits of wearing protective clothing include protection from chemical spills and splashes, biological hazards, personal comfort and hygiene, and compliance with safety regulations. By prioritizing safety through proper protective clothing, laboratory personnel can work more confidently and efficiently while minimizing potential risks to their health and well-being.

How do UV-protective fabrics influence the design of outdoor sportswear ?

The integration of UV-protective fabrics in the design of outdoor sportswear has significantly influenced its functionality and safety. Material selection, garment construction, aesthetics, and durability are key considerations in this process. Designers ensure that these garments offer protection from harmful UV rays while also being comfortable, durable, and visually appealing.

Is there a difference between PPE for medical use versus industrial use ?

The text discusses the differences between personal protective equipment (PPE) for medical use and industrial use. It explains that these differences mainly concern the level of protection required, the type of hazards encountered, and the specific features of the equipment designed to address those hazards. Medical professionals often deal with infectious diseases and thus require PPE that can protect them from pathogens like viruses and bacteria. This typically involves higher levels of protection, such as respiratory protection with N95 respirators or equivalent, which filter out airborne particles, and blood-borne pathogen protection with gloves, gowns, and face shields or goggles to prevent contact with blood and bodily fluids. Industrial workers face different types of hazards, including chemical exposure, physical injuries, and environmental factors. Their PPE tends to focus on chemical protection with protective suits, gloves, and boots made from materials resistant to specific chemicals or solvents, and physical protection with hard hats, safety glasses, and high-visibility clothing to prevent injuries from machinery or construction sites. The primary hazard in a medical setting is biological agents, such as viruses, bacteria, and other pathogens that may be present in patients' blood or other bodily fluids. Workers in industrial settings face a variety of hazards, including but not limited to chemical exposure from handling toxic substances, physical dangers from heavy machinery and equipment operation, and environmental risks such as extreme temperatures or noise pollution. PPE for medical use often includes features like fluid resistance with materials that are impermeable to liquids to prevent contamination, antimicrobial treatment with some PPE items having an antimicrobial coating to reduce the growth of microorganisms, and compatibility with other medical equipment designed to be used in conjunction with other medical tools and devices without interference. PPE for industrial use emphasizes features like durability with materials that can withstand harsh conditions and repeated use, comfort and mobility often lighter and more flexible materials to allow for ease of movement over long periods, and specialized functionality such as gloves having enhanced grip or shoes having steel toes for added protection against physical impacts.

How does protective clothing protect against radioactive substances ?

Protective clothing shields wearer from radiation exposure by acting as a barrier between them and the radioactive substance. Shielding materials used, such as lead or other heavy metals, reduce the radiation's intensity and prevent it from reaching the body. Thickness and density of the material are crucial in determining protection level. Maximum coverage area is necessary, including all skin surfaces and extremities. There are two main types: disposable (single-use) and reusable (can be cleaned and reused). Levels of protection vary depending on expected radiation exposure. Proper maintenance and care ensure effectiveness over time.

How does protective clothing work to prevent exposure to hazardous materials ?

Protective clothing shields wearers from hazardous materials through barrier materials, sealed enclosures, breathability features, and disposability. Its effectiveness depends on proper training, fit, maintenance, and responsible disposal practices.

How often should chemical protective gear be replaced or maintained ?

Chemical protective gear is essential for workers exposed to hazardous chemicals. The frequency of replacement or maintenance depends on the type of gear, level of exposure, and manufacturer's recommendations. Regular visual inspections and testing are crucial to ensure that the gear remains effective and safe. By following the manufacturer's guidelines, workers can minimize their risk of exposure to hazardous chemicals and protect their health and well-being.

Are lithium batteries safe to use ?

Lithium batteries have become an integral part of modern technology, powering a wide range of devices from smartphones to electric vehicles. However, concerns about their safety have been raised due to incidents of overheating and fires. In this article, we will explore the safety aspects of lithium batteries and provide guidance on how to use them safely. One of the main safety concerns with lithium batteries is the risk of overheating and catching fire. This can occur if the battery is damaged, improperly charged, or exposed to extreme temperatures. When a lithium battery overheats, it can cause a chemical reaction that leads to thermal runaway, which is a self-sustaining process that can result in a fire or explosion. Another safety concern associated with lithium batteries is the potential for chemical hazards. The chemicals used in lithium batteries can be toxic and harmful to human health if they are ingested, inhaled, or come into contact with skin or eyes. It is important to handle these batteries with care and dispose of them properly to avoid any potential risks. To minimize the risks associated with lithium batteries, it is essential to follow some basic safety tips: 1. Use genuine products from reputable manufacturers to ensure that the battery meets safety standards. 2. Avoid overcharging by not leaving your device charging unattended and avoiding using cheap chargers that may overcharge the battery. 3. Store your lithium batteries in a cool, dry place away from direct sunlight and extreme temperatures. 4. Inspect your batteries regularly for any signs of damage or swelling, and replace them if necessary. 5. Dispose of your old lithium batteries properly by taking them to a recycling center or following the manufacturer's instructions. 6. Follow the manufacturer's guidelines for your specific device and battery. 7. Keep lithium batteries out of reach of children as they may pose a choking hazard. 8. Use protective cases or covers for your devices to prevent damage to the battery. 9. Avoid dropping or mishandling your device as this can damage the battery and increase the risk of overheating. 10. Seek professional help if you notice any issues with your battery, such as swelling or leakage. In conclusion, while there are some safety concerns associated with lithium batteries, following these safety tips can help reduce the risks and ensure that you use them safely. By being cautious and responsible, you can enjoy the benefits of these powerful batteries without compromising your safety.

Can protective clothing be reused after being exposed to chemicals or biological agents ?

The reusability of protective clothing after exposure to chemicals or biological agents is determined by factors such as the type of garment, nature of contaminants, and level of exposure. Potential risks include inadequate decontamination, material degradation, and cross-contamination. Best practices for handling and disposal involve immediate removal, proper storage, appropriate decontamination processes, and safe disposal methods like incineration or landfill disposal according to local regulations. Adherence to these practices is crucial for maintaining safety and preventing further contamination.

What role do personal protective equipment (PPE) play in maintaining biosafety ?

PPE is vital for maintaining biosafety by preventing exposure to harmful biological agents, reducing contamination, complying with regulations, and promoting safety awareness. Types of PPE include physical barriers like gloves and gowns, eye and face protection, respiratory protection, and head protection. Best practices involve ensuring proper fit, following correct donning and doffing procedures, replacing damaged or contaminated PPE, storing it properly, and regularly inspecting it for wear or damage.

Is there a standard size for protective clothing, or can it be customized for individual needs ?

The topic of this text is protective clothing, focusingThe topic of this text is protective clothing, focusing there is a standard size for focusing on the question of whether there is a standard size for such garments or if they can be customized to meet individual needs. The text explores the advantages and disadvantages of both standard sizes and customization options in terms of consistency, cost-effectiveness, ease of use, fit, accommodation for unique requirements, performance, availability, and production time. It concludes that while standard sizes offer consistency and affordability, customization allows for a tailored fit that prioritizes comfort and protection but comes at a higher cost and longer production time. The choice between standard sizes and customization depends on factors such as job requirements, budget constraints, and personal preferences.

What types of chemicals require specialized personal protective equipment (PPE) ?

When working with hazardous chemicals, it is crucialWhen working with hazardous chemicals, it is crucial protective equipment (PPE) it is crucial to use the appropriate personal protective equipment (PPE) to ensure safety and prevent exposure. Here are some types of chemicals that require specialized PPE: Corrosive Chemicals: When handling corrosive chemicals, wear chemical-resistant gloves, aprons or gowns, safety goggles or face shields, and respiratory protection if necessary. Toxic Chemicals: When handling toxic chemicals, wear nitrile or chemical-resistant gloves, lab coats or coveralls, safety goggles or face shields, and respiratory protection depending on the type of toxic chemical. Flammable Chemicals: When handling flammable chemicals, wear flame-resistant clothing, gloves made from materials like nitrile or neoprene, safety goggles or face shields, and respiratory protection if necessary. Radioactive Chemicals: When handling radioactive chemicals, wear lead aprons or shields, gloves made from materials like latex or vinyl, safety goggles or face shields, and respiratory protection if necessary.

What is the role of personal protective equipment (PPE) in ensuring construction site safety ?

The article discusses the crucial role of Personal Protective Equipment (PPE) in ensuring safety on construction sites. It emphasizes the importance of PPE in protecting workers from physical, chemical, biological, and environmental hazards. The article also highlights the legal implications of not using PPE, as well as its potential to enhance worker productivity. Furthermore, it outlines various types of PPE used on construction sites, such as head protection, eye and face protection, hearing protection, hand protection, foot protection, respiratory protection, and fall protection. The article also provides best practices for using PPE effectively, including proper fit and comfort, maintenance and replacement, training and awareness, and storage and accessibility. Finally, the article concludes that PPE is an essential component of any construction project's health and safety protocols.

What is the importance of personal protective equipment (PPE) in the workplace ?

The Importance of Personal Protective Equipment (PPE) in the Workplace Personal protective equipment (PPE) is essential in the workplace to ensure the safety and health of employees. PPE includes items such as gloves, goggles, masks, hearing protection, and more. Here are some reasons why PPE is important: - Protection from Hazards: PPE protects workers from various hazards that may be present in their work environment, such as chemicals, biological agents, radiological materials, physical hazards, and mechanical hazards. - Compliance with Regulations: Employers are required by law to provide a safe and healthy working environment for their employees, which includes providing appropriate PPE when necessary. - Reduced Workplace Accidents: PPE can help prevent accidents in the workplace by protecting workers from harm, such as cuts, burns, and eye injuries. - Improved Employee Morale: Providing PPE shows employees that their employer values their safety and wants them to return home safely at the end of each workday, which can lead to improved morale and job satisfaction.

How can I safely move an injured person without causing further harm ?

Moving an injured person requires caution and care to avoid causing further harm. Here are some guidelines to follow: 1. Assess the situation and determine whether it's necessary to move the person immediately. 2. Call for emergency medical services or ask someone else to do so. 3. Protect yourself by wearing appropriate protective gear, such as gloves and masks. 4. Get assistance from others who are nearby. 5. Use proper techniques to minimize the risk of further harm, such as keeping the spine straight and supporting the head and neck. 6. Use equipment designed for moving injured persons, such as a stretcher or backboard. 7. Be gentle and careful when handling the injured person to avoid exacerbating their injuries.

How often should I use a language learning app to see significant improvement ?

To see significant improvement with a language learning app, it's recommended to use the app daily for at least 10-15 minutes, setting weekly targets and focusing on consistency over intensity. Combining app use with real-world interactions and adjusting your routine based on progress tracking are also key strategies.

Can I use multiple coupon codes on a single transaction ?

The ability to use multiple coupon codes on a single transaction varies by retailer. Some, like Amazon and Target, allow it while others, such as Best Buy and Macy's, do not. To maximize savings, shoppers should read coupon terms carefully, stack coupons when allowed, use them wisely, sign up for newsletters, and follow retailers on social media for exclusive offers.

What are the safety regulations for electrical work ?

Electrical work involves a high level of risk, and it is essential to follow strict safety regulations to prevent accidents and injuries. Here are some of the key safety regulations for electrical work: - Always wear appropriate personal protective equipment (PPE), such as insulated gloves, safety glasses, and non-conductive shoes. - Turn off the power before starting any electrical work, and use a lockout/tagout system to prevent accidental energization of equipment. - Use insulating materials and tools designed for live work when working near live circuits. - Assess confined spaces for potential hazards before entering and use ventilation systems to maintain safe air quality. - Only qualified personnel should work with high voltage circuits, using specialized tools and following specific procedures for testing and inspection. - Know emergency procedures, including the location of emergency equipment and how to call for help.