Safety Hazard

What are the OSHA standards for electrical safety in the workplace ?

OSHA has established standards for electrical safety in the workplace to protect employees from hazards associated with electricity. These standards cover training, lockout/tagout procedures, arc flash hazard protection, grounding and bonding, and maintenance of electrical wiring and equipment. Specific requirements vary depending on the type of workplace, such as construction sites, industrial settings, and office environments. By following these standards and implementing appropriate controls, employers can create a safe work environment and reduce the risk of electrical accidents and injuries.

What are the most common workplace safety hazards ?

The most common workplace safety hazards include slips, trips, and falls, fires and explosions, electrical hazards, chemical exposure, repetitive strain injuries (RSIs), noise-induced hearing loss (NIHL), violence and harassment, and ergonomic hazards. Employers should conduct regular risk assessments and provide appropriate training and personal protective equipment (PPE) to mitigate these hazards. Employees should report any potential hazards to their supervisors and participate in safety meetings and training sessions.

What are some common safety hazards that children should be aware of ?

Children should be aware of various safety hazards to ensure their well-being, including stranger danger, traffic rules, water safety, fire safety measures, electrical safety, choking hazards, falls and injuries, poisonous substances, internet safety, and natural disasters. They should know how to identify potential threats and take appropriate precautions to prevent accidents or injuries.

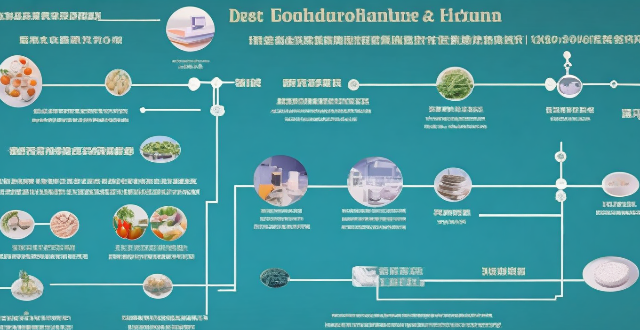

What is HACCP (Hazard Analysis and Critical Control Points) and why is it important for food safety ?

HACCP(危害分析和关键控制点)是确保食品安全的重要工具,通过识别、评估和控制食品安全危害的系统方法来预防潜在风险。该系统侧重于预防而非依赖最终产品测试,包括识别生物、化学和物理危害,确定并实施关键控制点(CCPs),以及进行监测和验证以确保CCPs有效执行。同时,记录保持和持续改进也是HACCP系统的关键组成部分,有助于食品行业减少食源性疾病暴发的风险,保护公众健康。

Can you explain the Hazard Analysis and Critical Control Points (HACCP) system ?

本文介绍了危害分析和关键控制点(HACCP)系统,这是一种系统的食品安全管理方法,涉及生产过程中危害的识别、评估和控制。文章讨论了HACCP系统的关键方面,包括其七个原则:进行危害分析、识别关键控制点(CCPs)、为每个CCP建立临界限制、监控CCPs、建立纠正措施、验证HACCP系统的有效运行以及保持记录和文档。实施HACCP有助于预防食源性疾病,提高产品质量,减少浪费并增强客户满意度。通过遵循HACCP原则,公司可以展示其对食品安全的承诺并遵守监管要求。

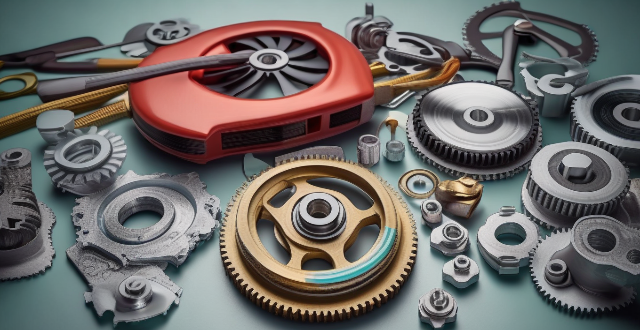

Are there any safety concerns associated with using a combination motor drive ?

The text discusses the safety concerns associated with using combination motor drives, which combine the functions of an electric motor and a gearbox. Safety issues include electrical hazards such as overheating and electrical shock, mechanical hazards like gearbox failure and injuries from rotating parts, and chemical hazards from lubricants and fluids. To ensure safe operation, it is important to follow proper safety procedures, regularly maintain the equipment, and use appropriate personal protective equipment.

How can we improve safety measures in the construction industry ?

Improving safety measures in the construction industry is crucial for protecting workers and ensuring project completion without delays. A comprehensive approach to enhancing safety includes implementing rigorous training programs, developing comprehensive safety policies, enforcing the use of personal protective equipment (PPE), conducting regular inspections and maintenance, promoting a safety culture, utilizing modern technology, improving housekeeping and orderliness, conducting risk assessments, adopting best practices, and partnering with safety organizations. By prioritizing safety measures, the construction industry can significantly reduce accidents and create a secure environment for all stakeholders involved.

How do safety drills help identify potential hazards in the workplace ?

Safety drills are crucial exercises to simulate and identify potential hazards in the workplace. They help highlight weak links in safety procedures, test equipment and infrastructure, enhance visibility of hazardous areas, train for unexpected circumstances, and promote a culture of safety. By conducting regular drills, organizations can reduce accidents and ensure a safer environment for employees.

What are the different types of safety signs and their meanings ?

This text describes the different types of safety signs and their meanings. Prohibition, warning, mandatory, fire safety, first aid, and information signs are all used to provide important safety information in a variety of environments. Each type of sign has a specific shape, color, and symbol or text that conveys a particular message about what actions should or should not be taken.

Can you explain the Occupational Safety and Health Administration (OSHA) safety regulations ?

The text provides an introduction to OSHA safety regulations, which are enforced by the United States' federal agency, Occupational Safety and Health Administration. The goal of these regulations is to ensure safe and healthy working conditions for employees. The text covers several topics including: 1) General Duty Clause, which requires employers to provide a workplace free from recognized hazards; 2) Specific Standards, which cover various topics such as electrical wiring and equipment, hazardous chemicals and substances, and fire prevention and protection; 3) Recordkeeping, which requires employers to maintain accurate records of work-related injuries and illnesses; 4) Inspections, which are conducted by OSHA compliance officers to ensure compliance with safety regulations; and 5) Training and Education, which are provided by OSHA to help employers and employees understand their rights and responsibilities under safety regulations. The text concludes that OSHA safety regulations are essential for ensuring employee health and safety in the workplace, and employers must comply with these regulations to avoid legal consequences and create a safe working environment for their workers.

What is the role of respirators in chemical protection, and how are they classified ?

Respirators play a crucial role in chemical protection by filtering out harmful particles and chemicals from the air. They are designed to protect workers from inhaling toxic substances, such as gases, vapors, and particulate matter, that may be present in their work environment. Respirators are essential for ensuring worker safety and preventing respiratory diseases caused by exposure to hazardous chemicals. Respirators can be classified into two main categories based on their design and function: air-purifying respirators (APRs) and atmosphere-supplying respirators (ASRs). APRs remove contaminants from the air before it is inhaled, while ASRs provide clean air from an external source through a hose or pipeline. When selecting a respirator for chemical protection, several factors must be considered, including the type of hazard, level of protection required, fit and comfort, and maintenance and care. By understanding the different types of respirators and selecting the appropriate one based on the specific hazard, employers can help ensure the safety and health of their employees.

How can schools improve their food safety standards ?

Improving food safety standards in schools is crucial for protecting the health of students and staff. Here are some ways that schools can enhance their food safety practices: 1. Implement a HACCP System 2. Train Staff on Food Safety 3. Use Proper Handling and Cooking Techniques 4. Maintain Cleanliness and Sanitation 5. Enforce Strict Ingredient Sourcing Policies 6. Establish Clear Policies for Illness Reporting 7. Conduct Regular Audits and Reviews

What are the legal requirements for displaying safety signs in a workplace ?

Legal Requirements for Displaying Safety Signs in a Workplace: Identify hazards, provide clear messages, ensure visibility, use standardized design, maintain signs, comply with regulations, and provide training.

Why is it important to have regular safety training for construction workers ?

Construction sites are dangerous places with numerous potential hazards. Regular safety training for construction workers is essential to mitigate these risks. It enhances awareness of potential hazards, promotes a culture of safety, and ensures compliance with regulations and standards. Ongoing education and training helps workers identify new hazards, develop preventive measures, build a shared responsibility for safety, reinforce safe work habits, meet legal requirements, and maintain insurance coverage. By investing in regular safety training, construction companies can create safer work environments, protect their employees, and avoid costly fines and legal liabilities.

What role do safety regulations play in preventing workplace accidents ?

The role of safety regulations in preventing workplace accidents is crucial. They establish standards, provide training and education, enforce compliance, create a culture of safety, and reduce liability and costs. By adhering to these regulations, employers can protect their workforce and maintain a safe working environment.

What are some common electrical hazards ?

Electrical hazards are a common occurrence in homes, workplaces, and public areas. They can cause serious injuries or even death if not handled properly. Here are some of the most common electrical hazards: ## Overloaded Circuits An overloaded circuit occurs when too many appliances are plugged into a single outlet or circuit. This can cause the circuit to overheat, leading to a fire. It is important to distribute the load across multiple outlets and avoid using extension cords as permanent solutions. ## Faulty Wiring Faulty wiring is another common electrical hazard. This can occur due to poor installation, wear and tear, or damage to the wires. Faulty wiring can cause short circuits, sparks, and electrical shocks. Regular inspections and maintenance by a licensed electrician can help prevent this hazard. ## Water and Electricity Water and electricity do not mix. If water comes into contact with electrical devices or wiring, it can cause electrocution or electrical fires. It is important to keep electrical devices away from water sources and ensure that all electrical appliances are properly grounded. ## Ungrounded Outlets Ungrounded outlets lack a third prong that grounds the outlet to the earth. This can lead to electrical shocks and increase the risk of electrical fires. It is important to have all outlets in your home or workplace grounded for safety. ## Damaged Cords and Plugs Damaged cords and plugs are also common electrical hazards. If a cord is frayed or cracked, it can expose live wires and cause electrical shocks. Similarly, damaged plugs can cause sparks and short circuits. It is important to replace damaged cords and plugs immediately. ## Improper Use of Extension Cords Extension cords should only be used temporarily and never as a permanent solution for powering appliances. Overloading an extension cord can cause it to overheat and start a fire. It is important to use extension cords sparingly and ensure they are rated for the amount of power being drawn through them.

What is listeria and how does it relate to food safety, particularly in ready-to-eat foods ?

**Listeria: An Overview and Its Relation to Food Safety** The text provides an overview of Listeria, focusing on its relation to food safety. It explains that Listeria is a genus of bacteria, with *Listeria monocytogenes* being the most notable species in terms of food safety. This bacterium can cause listeriosis, a serious illness affecting vulnerable populations. The text highlights the prevalence of this bacterium in ready-to-eat foods, which are not intended to be cooked or reheated before consumption, making them potential vehicles for transmitting the bacterium directly to consumers. It lists high-risk RTE foods and discusses sources of contamination, control measures, and the importance of consumer awareness in ensuring food safety. Overall, the text emphasizes the significance of stringent food safety practices throughout the entire food supply chain and the role of consumer education in mitigating the risk of contamination and infection.

How often should safety signs be reviewed and updated in a facility ?

Safety signs should be reviewed annually and updated immediately when necessary to maintain a safe environment in a facility.

How do safety regulations apply to the mining industry ?

The text discusses safety regulations in the mining industry, emphasizing the importance of equipment maintenance, worker training, emergency response procedures, and personal protective equipment (PPE) requirements to ensure a safe working environment for employees. It highlights the need for regular inspections, maintenance schedules, repair protocols, initial and ongoing training, hazard identification, evacuation plans, first aid kits, communication systems, hard hats, gloves, safety glasses or goggles, and hearing protection as crucial elements of these regulations. The article concludes by stressing the significance of prioritizing safety above all else to minimize risks and prevent accidents in the mining industry.

How do you manage risks associated with working at height in construction ?

Managing risks associated with working at height in construction requires proper risk assessment, use of appropriate equipment and tools, worker training, implementation of control measures, and ongoing monitoring and review of safety measures. By following these strategies, you can help ensure the safety of workers and prevent accidents while working at height.

Can you explain the hierarchy of safety signage (i.e., prohibition, warning, mandatory, and emergency) ?

The hierarchy of safety signage is divided into four categories: prohibition, warning, mandatory, and emergency. Prohibition signs indicate actions that are not allowed, while warning signs alert individuals to potential hazards. Mandatory signs indicate required actions for safety, and emergency signs provide critical information during emergencies. Understanding this hierarchy is crucial for creating a safe work environment.

How can workplace accidents be prevented ?

Workplace accidents can be prevented through risk assessment, safety training, personal protective equipment (PPE), safe work procedures, equipment maintenance, open communication, and promoting a culture of safety. Leaders should prioritize safety and encourage employee participation in safety initiatives.

How do safety regulations affect the manufacturing industry ?

Safety regulations are critical in manufacturing for worker safety, environmental protection, and product quality assurance but can increase costs and administrative burden while potentially slowing innovation.

Is there a difference between PPE for medical use versus industrial use ?

The text discusses the differences between personal protective equipment (PPE) for medical use and industrial use. It explains that these differences mainly concern the level of protection required, the type of hazards encountered, and the specific features of the equipment designed to address those hazards. Medical professionals often deal with infectious diseases and thus require PPE that can protect them from pathogens like viruses and bacteria. This typically involves higher levels of protection, such as respiratory protection with N95 respirators or equivalent, which filter out airborne particles, and blood-borne pathogen protection with gloves, gowns, and face shields or goggles to prevent contact with blood and bodily fluids. Industrial workers face different types of hazards, including chemical exposure, physical injuries, and environmental factors. Their PPE tends to focus on chemical protection with protective suits, gloves, and boots made from materials resistant to specific chemicals or solvents, and physical protection with hard hats, safety glasses, and high-visibility clothing to prevent injuries from machinery or construction sites. The primary hazard in a medical setting is biological agents, such as viruses, bacteria, and other pathogens that may be present in patients' blood or other bodily fluids. Workers in industrial settings face a variety of hazards, including but not limited to chemical exposure from handling toxic substances, physical dangers from heavy machinery and equipment operation, and environmental risks such as extreme temperatures or noise pollution. PPE for medical use often includes features like fluid resistance with materials that are impermeable to liquids to prevent contamination, antimicrobial treatment with some PPE items having an antimicrobial coating to reduce the growth of microorganisms, and compatibility with other medical equipment designed to be used in conjunction with other medical tools and devices without interference. PPE for industrial use emphasizes features like durability with materials that can withstand harsh conditions and repeated use, comfort and mobility often lighter and more flexible materials to allow for ease of movement over long periods, and specialized functionality such as gloves having enhanced grip or shoes having steel toes for added protection against physical impacts.

How can technology improve workplace safety ?

The article discusses how technology can enhance workplace safety by using wearable devices to monitor employee health, Internet of Things (IoT) for environmental control, artificial intelligence and machine learning for hazard prediction, and drones and robotics for performing dangerous tasks.

How can parents effectively teach their children about safety ?

Teaching children about safety is crucial for their well-being. Parents can effectively teach their children about safety by establishing clear rules, educating them about potential dangers, practicing safety drills, encouraging open communication, and modeling safe behavior. By doing so, children will develop awareness and the ability to protect themselves from potential dangers.

Are lithium batteries safe to use ?

Lithium batteries have become an integral part of modern technology, powering a wide range of devices from smartphones to electric vehicles. However, concerns about their safety have been raised due to incidents of overheating and fires. In this article, we will explore the safety aspects of lithium batteries and provide guidance on how to use them safely. One of the main safety concerns with lithium batteries is the risk of overheating and catching fire. This can occur if the battery is damaged, improperly charged, or exposed to extreme temperatures. When a lithium battery overheats, it can cause a chemical reaction that leads to thermal runaway, which is a self-sustaining process that can result in a fire or explosion. Another safety concern associated with lithium batteries is the potential for chemical hazards. The chemicals used in lithium batteries can be toxic and harmful to human health if they are ingested, inhaled, or come into contact with skin or eyes. It is important to handle these batteries with care and dispose of them properly to avoid any potential risks. To minimize the risks associated with lithium batteries, it is essential to follow some basic safety tips: 1. Use genuine products from reputable manufacturers to ensure that the battery meets safety standards. 2. Avoid overcharging by not leaving your device charging unattended and avoiding using cheap chargers that may overcharge the battery. 3. Store your lithium batteries in a cool, dry place away from direct sunlight and extreme temperatures. 4. Inspect your batteries regularly for any signs of damage or swelling, and replace them if necessary. 5. Dispose of your old lithium batteries properly by taking them to a recycling center or following the manufacturer's instructions. 6. Follow the manufacturer's guidelines for your specific device and battery. 7. Keep lithium batteries out of reach of children as they may pose a choking hazard. 8. Use protective cases or covers for your devices to prevent damage to the battery. 9. Avoid dropping or mishandling your device as this can damage the battery and increase the risk of overheating. 10. Seek professional help if you notice any issues with your battery, such as swelling or leakage. In conclusion, while there are some safety concerns associated with lithium batteries, following these safety tips can help reduce the risks and ensure that you use them safely. By being cautious and responsible, you can enjoy the benefits of these powerful batteries without compromising your safety.

What safety measures are in place on cruise ships ?

Cruise ships implement various safety measures to ensure the well-being of passengers and crew, including muster drills, life-saving equipment, fire safety systems, medical facilities, security personnel, emergency response plans, navigation systems, and regular maintenance checks.

How can technology be used to enhance child safety education ?

Technology can significantly enhance child safety education through various strategies such as interactive learning applications, virtual reality experiences, online safety courses, wearable devices, and social media engagement. These tools not only make learning fun and engaging but also provide practical, real-world simulations that help children develop essential safety skills. By utilizing these modern methods, we can equip the younger generation with the knowledge and confidence needed to stay safe in a rapidly changing world.