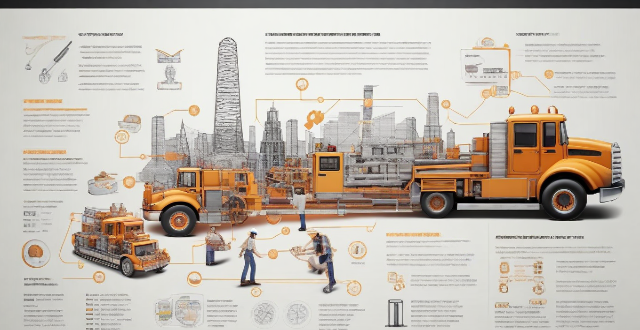

Safety Construction

How do weather conditions affect building safety during construction ?

The text discusses the impact of various weather conditions on building safety during construction. It highlights the risks associated with extreme heat, cold weather, rain and water, strong winds, snow and ice, and lightning and thunderstorms. The conclusion emphasizes the importance of monitoring weather forecasts and adjusting working procedures to ensure worker safety.

How often should safety inspections be conducted on a construction site ?

Safety inspections are crucial for construction sites to prevent accidents and ensure worker well-being. The frequency of these inspections depends on the project's size, complexity, type of work, and local regulations. This guide provides a detailed overview of how often safety inspections should be conducted: 1. Daily Inspections: Include visual checks, tools and equipment, and personal protective equipment (PPE). 2. Weekly Inspections: Cover structural integrity, electrical systems, and fire safety. 3. Monthly Inspections: Assess environmental hazards, emergency response plans, and site cleanliness. 4. Quarterly Inspections: Conduct comprehensive site assessments, review training updates, and ensure regulatory compliance. Unannounced spot checks should also be performed throughout the project to maintain safety awareness among workers. Safety should always be a top priority on any construction site, and regular inspections are essential for achieving this goal.

How can we improve safety measures in the construction industry ?

Improving safety measures in the construction industry is crucial for protecting workers and ensuring project completion without delays. A comprehensive approach to enhancing safety includes implementing rigorous training programs, developing comprehensive safety policies, enforcing the use of personal protective equipment (PPE), conducting regular inspections and maintenance, promoting a safety culture, utilizing modern technology, improving housekeeping and orderliness, conducting risk assessments, adopting best practices, and partnering with safety organizations. By prioritizing safety measures, the construction industry can significantly reduce accidents and create a secure environment for all stakeholders involved.

Why is it important to have regular safety training for construction workers ?

Construction sites are dangerous places with numerous potential hazards. Regular safety training for construction workers is essential to mitigate these risks. It enhances awareness of potential hazards, promotes a culture of safety, and ensures compliance with regulations and standards. Ongoing education and training helps workers identify new hazards, develop preventive measures, build a shared responsibility for safety, reinforce safe work habits, meet legal requirements, and maintain insurance coverage. By investing in regular safety training, construction companies can create safer work environments, protect their employees, and avoid costly fines and legal liabilities.

What is the role of personal protective equipment (PPE) in ensuring construction site safety ?

The article discusses the crucial role of Personal Protective Equipment (PPE) in ensuring safety on construction sites. It emphasizes the importance of PPE in protecting workers from physical, chemical, biological, and environmental hazards. The article also highlights the legal implications of not using PPE, as well as its potential to enhance worker productivity. Furthermore, it outlines various types of PPE used on construction sites, such as head protection, eye and face protection, hearing protection, hand protection, foot protection, respiratory protection, and fall protection. The article also provides best practices for using PPE effectively, including proper fit and comfort, maintenance and replacement, training and awareness, and storage and accessibility. Finally, the article concludes that PPE is an essential component of any construction project's health and safety protocols.

What are the consequences of ignoring safety standards in construction work ?

Ignoring safety standards in construction work can lead to severe consequences, including risk to human life, project delays, financial losses, reputation damage, legal implications, environmental impact, and public safety concerns. Adhering to these standards is crucial for the well-being of all involved parties and the success of the project.

How can technology be utilized to enhance safety protocols in construction projects ?

The text discusses how technology can enhance safety protocols in construction projects. Wearable technology, such as smart helmets and vests, drone technology for aerial surveillance and 3D mapping, Internet of Things (IoT) sensors for environmental and structural health monitoring, Virtual Reality (VR) and Augmented Reality (AR) for safety training and real-time information, and mobile applications for immediate communication and health monitoring are some of the tools and systems that have been developed to reduce risks and ensure the well-being of workers on site. The integration of these technologies is not just about introducing new gadgets, but about creating a culture of proactive risk management.

What are the legal requirements for health and safety training on a construction site ?

Legal Requirements for Health and Safety Training on a Construction Site: - Regulatory Bodies: OSHA, EPA, DOL - Types of Training: HAZWOPER, Confined Space Entry, Fall Protection, Electrical Safety, Scaffold Safety - Frequency of Training: Annual refresher courses, on-site training sessions before starting work, regular toolbox talks during work hours - Best Practices: Implementing a safety culture, providing adequate equipment and facilities, conducting regular safety meetings.

How does poor project management contribute to construction hazards ?

This text discusses the impact of poor project management on construction hazards, including inadequate planning, communication breakdown, ineffective risk management, unrealistic timelines and budgets, and inadequate supervision and training. It emphasizes the importance of effective project management practices for ensuring safety and success in construction projects.

What are some best practices for preventing falls at construction sites ?

Preventing falls at construction sites is crucial for worker safety. Best practices include using fall protection systems like safety nets, personal fall arrest systems, and guardrails; training workers on fall prevention; maintaining a clean and organized work area; conducting regular safety inspections; and ensuring workers wear proper footwear. Following these practices can help prevent accidents and keep workers safe.

How do you manage risks associated with working at height in construction ?

Managing risks associated with working at height in construction requires proper risk assessment, use of appropriate equipment and tools, worker training, implementation of control measures, and ongoing monitoring and review of safety measures. By following these strategies, you can help ensure the safety of workers and prevent accidents while working at height.

How do building energy efficiency standards affect the construction industry ?

Building energy efficiency standards have a significant impact on the construction industry by affecting cost implications, design philosophy, regulatory compliance, and market trends. These standards require higher initial costs due to advanced technologies and materials but offer long-term benefits like reduced energy consumption and maintenance costs. They also shift the focus of design towards energy performance and sustainability, leading to integrated design processes and innovative solutions. Compliance with these standards is crucial to avoid penalties and legal issues, while certifications like LEED or WELL can provide a competitive advantage. Finally, building energy efficiency standards influence market trends by driving demand for sustainable construction methods and educating clients about their benefits.

What is green building and why is it important for the construction industry ?

Green building is an approach to design, construction, operation, and maintenance of buildings that aims to minimize environmental impact and resource consumption throughout a building's lifecycle. It focuses on sustainability, energy efficiency, water conservation, materials selection, and indoor environmental quality. The importance of green building in the construction industry stems from environmental concerns, economic benefits, and social responsibility. Green buildings reduce carbon footprint, conserve resources, preserve biodiversity, save energy costs, have higher asset values, and promote healthier living conditions. They also set community standards for sustainable practices and help companies stay ahead of compliance requirements. Green building drives innovation in materials science, design techniques, and construction technology. Overall, green building represents a fundamental shift towards more sustainable and responsible practices within the construction industry.

In what ways do building codes contribute to overall structural safety ?

Building codes are regulations that ensure the design, construction, and maintenance of buildings adhere to certain standards, promoting structural safety. They prevent the use of substandard materials and shoddy workmanship, require buildings to withstand environmental factors, mandate fire-resistant materials and safety features, address accessibility and egress issues, and encourage energy efficiency. Overall, building codes contribute significantly to creating safer, more resilient structures.

How often should workplace safety inspections be conducted ?

The frequency of workplace safety inspections is determined by factors like the nature of the business, potential hazards, and regulatory requirements. High-risk industries need more frequent checks, while low-risk ones can be less frequent. Identifying potential hazards, such as physical, chemical, or biological risks, is crucial for setting inspection schedules. Legal requirements, including OSHA guidelines and local regulations, also play a significant role. Adopting best practices like regular training, encouraging employee reports, and periodic reviews can further enhance safety. Overall, a proactive approach to safety inspections helps create a secure work environment.

Are there any legal requirements for personal safety training that businesses need to comply with ?

The article discusses the legal requirements for personal safety training in businesses. Under the Occupational Health and Safety Act (OHSA), employers have a duty of care towards their employees to provide a safe working environment, including adequate personal safety training. Some industries may have specific regulations related to personal safety training, such as the construction industry requiring workers to undergo specific safety training courses. While not mandatory, some businesses may choose to follow voluntary standards and obtain certifications related to workplace health and safety, which often include requirements for personal safety training. In conclusion, businesses are legally required to provide personal safety training to their employees under the OHSA, with additional requirements possible depending on the industry.

Are there any safety concerns associated with using a combination motor drive ?

The text discusses the safety concerns associated with using combination motor drives, which combine the functions of an electric motor and a gearbox. Safety issues include electrical hazards such as overheating and electrical shock, mechanical hazards like gearbox failure and injuries from rotating parts, and chemical hazards from lubricants and fluids. To ensure safe operation, it is important to follow proper safety procedures, regularly maintain the equipment, and use appropriate personal protective equipment.

What are the safety regulations for working at heights ?

This article discusses the importance of safety regulations for working at heights, including general safety measures and specific safety regulations. It emphasizes the need for proper training and education, personal protective equipment, inspection and maintenance of equipment, and work area preparation. The article also covers fall protection systems, ladder safety, and scaffolding safety. Overall, it highlights the significance of prioritizing safety when working at heights to minimize the risk of accidents and ensure worker well-being.

How often should personal safety training be conducted for employees ?

Personal safety training is crucial for workplace safety and should be conducted regularly. The frequency of training depends on factors such as the nature of the job, level of risk involved, and organization's policies. Recommended frequencies include annual, quarterly, monthly, and on-the-job training. By considering these factors, organizations can ensure that employees are well-prepared to handle potential accidents and emergencies.

How do safety regulations influence the use of protective equipment in the workplace ?

Safety regulations play a crucial role in ensuring that workers use protective equipment in the workplace. They enforce compliance by requiring employers to provide necessary protective equipment to their employees, mandate regular training sessions for workers about the importance of using protective equipment, conduct safety inspections periodically to ensure that protective equipment is up-to-date, functional, and used correctly, and drive continuous improvement based on new technologies, changing work environments, and lessons learned from incidents. These measures collectively create a safer work environment for all employees.

How do safety regulations affect the manufacturing industry ?

Safety regulations are critical in manufacturing for worker safety, environmental protection, and product quality assurance but can increase costs and administrative burden while potentially slowing innovation.

What are the essential elements of an effective emergency response plan for construction sites ?

An effective emergency response plan for construction sites is essential to ensure safety, minimize damage, and comply with legal requirements. Key components include hazard identification, prevention measures, emergency procedures, recovery strategies, coordination, and legal compliance. Implementation involves training, drills, and regular updates based on feedback and incident debriefing.

How can parents effectively teach their children about safety ?

Teaching children about safety is crucial for their well-being. Parents can effectively teach their children about safety by establishing clear rules, educating them about potential dangers, practicing safety drills, encouraging open communication, and modeling safe behavior. By doing so, children will develop awareness and the ability to protect themselves from potential dangers.

What safety measures are in place on cruise ships ?

Cruise ships implement various safety measures to ensure the well-being of passengers and crew, including muster drills, life-saving equipment, fire safety systems, medical facilities, security personnel, emergency response plans, navigation systems, and regular maintenance checks.

How can technology be used to enhance child safety education ?

Technology can significantly enhance child safety education through various strategies such as interactive learning applications, virtual reality experiences, online safety courses, wearable devices, and social media engagement. These tools not only make learning fun and engaging but also provide practical, real-world simulations that help children develop essential safety skills. By utilizing these modern methods, we can equip the younger generation with the knowledge and confidence needed to stay safe in a rapidly changing world.

What is the importance of using standardized safety symbols and colors on safety signs ?

Using standardized safety symbols and colors on safety signs is crucial for promoting a safe working environment. These signs convey clear, concise information to employees, visitors, and emergency responders about potential hazards and necessary precautions. The importance of these symbols and colors in enhancing safety awareness and reducing accidents will be discussed in this response.

What are the most common workplace safety hazards ?

The most common workplace safety hazards include slips, trips, and falls, fires and explosions, electrical hazards, chemical exposure, repetitive strain injuries (RSIs), noise-induced hearing loss (NIHL), violence and harassment, and ergonomic hazards. Employers should conduct regular risk assessments and provide appropriate training and personal protective equipment (PPE) to mitigate these hazards. Employees should report any potential hazards to their supervisors and participate in safety meetings and training sessions.

What are the legal requirements for workplace safety ?

Legal requirements for workplace safety include compliance with occupational health and safety laws, implementation of a health and safety management system, provision of personal protective equipment (PPE), reporting of injuries and illnesses, and employee participation in health and safety decisions. These measures ensure the well-being of employees and protect the company from potential legal liabilities.

How do safety drills help identify potential hazards in the workplace ?

Safety drills are crucial exercises to simulate and identify potential hazards in the workplace. They help highlight weak links in safety procedures, test equipment and infrastructure, enhance visibility of hazardous areas, train for unexpected circumstances, and promote a culture of safety. By conducting regular drills, organizations can reduce accidents and ensure a safer environment for employees.

How can we measure the success of a safety drill ?

The article discusses the importance of evaluating safety drills to improve emergency response and preparedness. Key factors to consider include compliance with safety procedures, participant engagement, effectiveness of communications, availability and functionality of equipment and resources, and overall performance. By measuring the success of a safety drill, organizations can identify areas for improvement and ensure that their employees are well-prepared to handle emergency situations effectively.