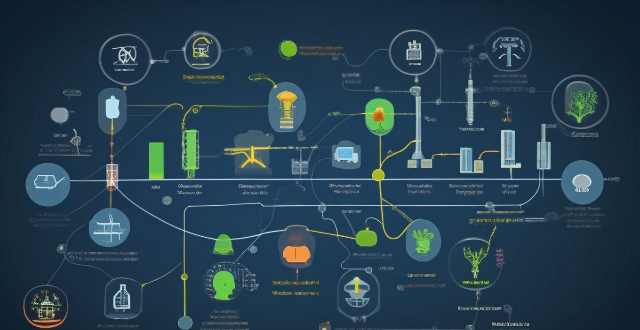

The most effective methods for improving industrial energy efficiency include process optimization, using energy-efficient equipment, harnessing renewable energy sources, thermal management, power management, employee training and awareness, employing energy information systems, and complying with policy and regulatory standards. These methods can reduce operational costs, conserve resources, and minimize environmental impact.

Most Effective Methods for Improving Industrial Energy Efficiency

Improving industrial energy efficiency is crucial in reducing operational costs, conserving resources, and minimizing environmental impact. Here are some of the most effective methods:

1. Process Optimization

- Energy Audits: Conduct comprehensive energy audits to identify areas of energy waste and inefficiency.

- Lean Manufacturing: Implement lean manufacturing principles to streamline processes and reduce energy consumption.

- Process Control: Use advanced process control systems to optimize energy usage during production.

2. Energy-Efficient Equipment

- High-Efficiency Machinery: Upgrade to high-efficiency machinery that uses less energy to perform the same tasks.

- Maintenance Programs: Establish regular maintenance programs to ensure equipment operates at peak efficiency.

- Replace Old Equipment: Replace old, outdated equipment with modern, energy-efficient models.

3. Renewable Energy Sources

- Solar Power: Install solar panels to harness solar energy for industrial use.

- Wind Power: Utilize wind turbines where feasible to generate electricity.

- Bioenergy: Use biomass from agricultural waste or dedicated energy crops as a renewable fuel source.

4. Thermal Management

- Insulation: Properly insulate buildings and equipment to reduce heat loss or gain.

- Heat Recovery Systems: Install heat recovery systems to capture waste heat for reuse.

- Thermal Wheels: Use thermal wheels in ventilation systems to preheat incoming air with outgoing air.

5. Power Management

- Energy-Efficient Lighting: Switch to LED or other energy-efficient lighting solutions.

- Motion Sensors: Install motion sensors to automatically turn off lights and equipment when not in use.

- Power Quality Management: Ensure power quality management to prevent energy losses due to voltage fluctuations.

6. Employee Training and Awareness

- Training Programs: Offer training programs on energy conservation practices.

- Awareness Campaigns: Run awareness campaigns to encourage employees to adopt energy-saving habits.

- Recognition and Rewards: Implement recognition and reward systems for employees who contribute to energy savings.

7. Energy Information Systems

- Monitoring and Targeting (M&T): Implement M&T protocols to track energy consumption and set reduction targets.

- Building Automation Systems: Use building automation systems to optimize heating, ventilation, and air conditioning (HVAC) operations.

- Data Analytics: Leverage data analytics to identify trends and opportunities for energy savings.

8. Policy and Regulatory Compliance

- Government Incentives: Take advantage of government incentives for energy-efficient upgrades.

- Environmental Standards: Adhere to environmental standards and regulations that promote energy efficiency.

- Carbon Footprint Reduction: Implement strategies to actively reduce the company's carbon footprint.

By employing these methods, industries can significantly improve their energy efficiency, leading to cost savings, increased competitiveness, and a reduced environmental impact.