This article compares the efficiency of an electromagnetic motor with other types of motors such as DC motors, AC motors, stepper motors, and servo motors. Electromagnetic motors have a high efficiency rate, typically ranging from 80% to 95%, making them suitable for applications where energy consumption is a concern. DC motors have lower efficiency rates, typically around 50% to 70%, while AC motors have higher efficiency rates, up to 95% or more, but are generally less efficient than electromagnetic motors due to losses in the windings and core. Stepper motors have relatively low efficiency rates compared to other types of motors, typically around 30% to 50%, while servo motors have moderate efficiency rates, typically around 60% to 80%. Overall, the choice of motor depends on various factors such as cost, size, weight, and required performance characteristics.

Efficiency of an Electromagnetic Motor Compared to Other Motors

Introduction

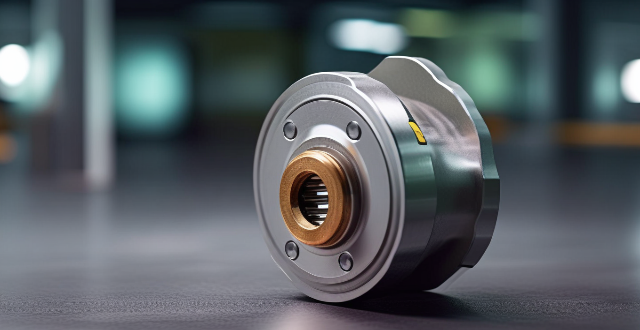

An electromagnetic motor is a type of electric motor that uses the principles of electromagnetism to generate mechanical energy. It consists of a rotor (the moving part) and a stator (the stationary part). The efficiency of an electromagnetic motor depends on various factors such as the design, materials used, and operating conditions. In this article, we will compare the efficiency of an electromagnetic motor with other types of motors.

Types of Motors

Before comparing the efficiency of an electromagnetic motor with other types of motors, let's briefly discuss some common types of motors:

1. DC Motors: These motors use direct current (DC) to operate and are commonly used in battery-powered devices.

2. AC Motors: These motors use alternating current (AC) to operate and are widely used in industrial applications.

3. Stepper Motors: These motors move in precise steps and are commonly used in robotics and CNC machines.

4. Servo Motors: These motors provide precise control over position, velocity, and acceleration and are commonly used in robotics and automation systems.

Efficiency Comparison

Now let's compare the efficiency of an electromagnetic motor with other types of motors:

Electromagnetic Motors

Electromagnetic motors have a high efficiency rate, typically ranging from 80% to 95%. This means that most of the electrical energy supplied to the motor is converted into mechanical energy, with only a small portion lost as heat or other forms of energy dissipation. The high efficiency of electromagnetic motors makes them suitable for applications where energy consumption is a concern, such as electric vehicles and renewable energy systems.

DC Motors

The efficiency of DC motors varies depending on their design and size. Small DC motors, such as those found in toys and electronic devices, have lower efficiency rates, typically around 50% to 70%. Larger DC motors, such as those used in electric vehicles and industrial equipment, can have higher efficiency rates, up to 90% or more. However, they are generally less efficient than electromagnetic motors due to losses in the commutator and brushes.

AC Motors

The efficiency of AC motors also varies depending on their design and size. Small AC motors, such as those found in household appliances, have lower efficiency rates, typically around 60% to 80%. Larger AC motors, such as those used in industrial equipment and HVAC systems, can have higher efficiency rates, up to 95% or more. However, they are generally less efficient than electromagnetic motors due to losses in the windings and core.

Stepper Motors

Stepper motors have relatively low efficiency rates compared to other types of motors, typically around 30% to 50%. This is because stepper motors are designed for precision rather than efficiency, and they require additional power to maintain their position and hold torque. However, recent advancements in stepper motor technology have led to improvements in efficiency.

Servo Motors

Servo motors have moderate efficiency rates compared to other types of motors, typically around 60% to 80%. This is because servo motors are designed for precise control rather than maximum efficiency, and they require additional power for feedback control mechanisms. However, recent advancements in servo motor technology have led to improvements in efficiency.

Conclusion

In conclusion, electromagnetic motors have the highest efficiency rates among all types of motors discussed in this article. Their high efficiency makes them suitable for applications where energy consumption is a concern, such as electric vehicles and renewable energy systems. However, the choice of motor depends on various factors such as cost, size, weight, and required performance characteristics.