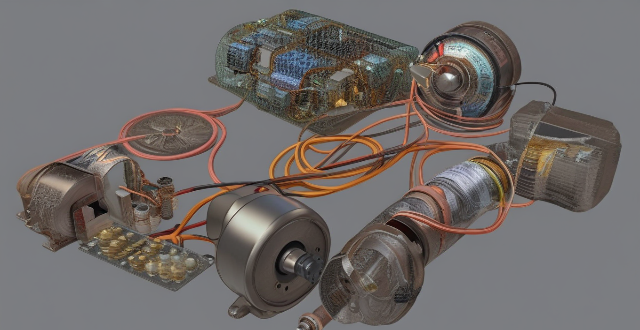

Electromagnetic motors are electric motors that use electromagnetic force to convert electrical energy into mechanical energy. They consist of a stator (stationary part) and a rotor (rotating part), along with components like a commutator, brushes, and an armature. The operation involves generating magnetic fields, current flow in rotor coils, interaction between these fields, continuous rotation facilitated by the commutator, and mechanical output through the shaft. Types include DC motors, AC motors, stepper motors, and universal motors, each suitable for different applications.

What is an Electromagnetic Motor?

An electromagnetic motor is a type of electric motor that uses electromagnetic force to convert electrical energy into mechanical energy. It operates on the principle of interaction between magnetic fields and current-carrying conductors. Let's delve deeper into understanding the components and operation of an electromagnetic motor.

Key Components of an Electromagnetic Motor:

1. Stator (Stationary Part): This is the outer part of the motor, which produces a magnetic field using either permanent magnets or an electromagnet created by winding wire around a core.

2. Rotor (Rotating Part): The rotor is located inside the stator and contains a series of coils or permanent magnets. When electricity flows through these coils, it generates a magnetic field.

3. Commutator: In some types of electromagnetic motors, such as DC motors, a commutator is used to switch the direction of current in the rotor coils, allowing continuous rotation.

4. Brushes: These are metal contacts that transfer electrical current from the static wires to the rotating parts of the motor.

5. Armature: The armature is the rotating coil or set of coils in which current flows and interacts with the magnetic field to produce motion.

6. Shaft: The shaft is connected to the rotor and transmits the mechanical motion produced by the motor to perform work.

How Does an Electromagnetic Motor Work?

Steps Involved in the Operation:

1. Magnetic Field Generation: The stator generates a magnetic field, either through permanent magnets or an electromagnet.

2. Current Flow in Rotor Coils: When electricity flows through the rotor coils, it creates another magnetic field.

3. Interaction Between Fields: The magnetic field of the rotor interacts with the stationary magnetic field of the stator. According to Lenz's law, this interaction causes the rotor to move.

4. Continuous Rotation: As the rotor turns, the commutator reverses the direction of current in the rotor coils for DC motors, ensuring continuous rotation. For AC motors, the alternating nature of the current naturally changes the direction of the magnetic field.

5. Mechanical Output: The movement of the rotor is transmitted via the shaft to perform the desired mechanical work.

Types of Electromagnetic Motors:

- DC Motors: Use direct current and often include a commutator for continuous rotation.

- AC Motors: Operate on alternating current and can be synchronous or asynchronous based on their rotor speed relative to the frequency of the supply current.

- Stepper Motors: Move in precise steps controlled by electrical pulses sent to its coils.

- Universal Motors: Can run on both AC and DC and are commonly found in portable power tools.

In summary, an electromagnetic motor is a versatile machine that harnesses the power of electromagnetism to convert electrical energy into mechanical motion, serving a wide range of applications from home appliances to industrial machinery.